Linear temperature sensing element equipped with fused insulating layer and pressure-sensitive rubber layer

A technology of rubber layer and insulating layer, applied in the field of online temperature sensing components, can solve the problems of false alarm, decrease of detector alarm accuracy, adverse effect of alarm parameters, etc., and achieve the effect of eliminating influence and improving alarm accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

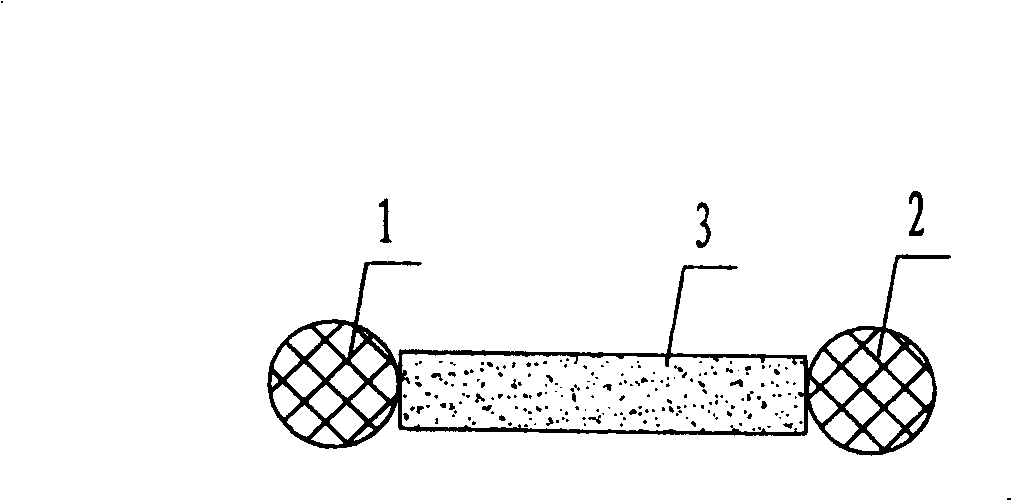

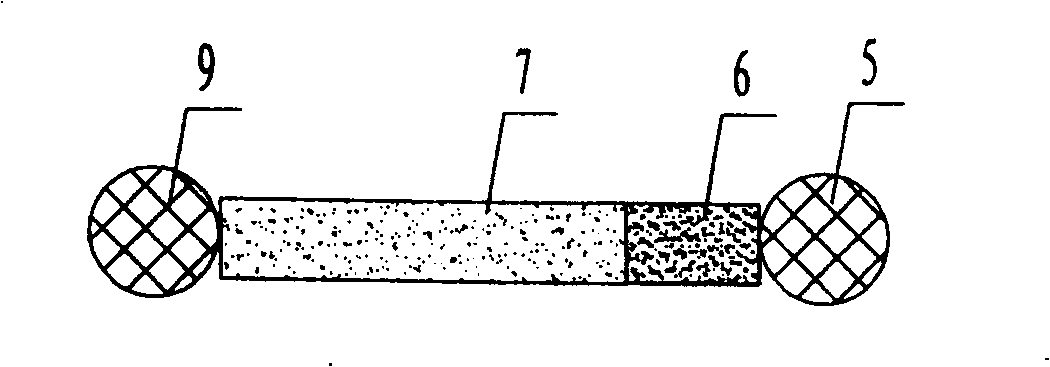

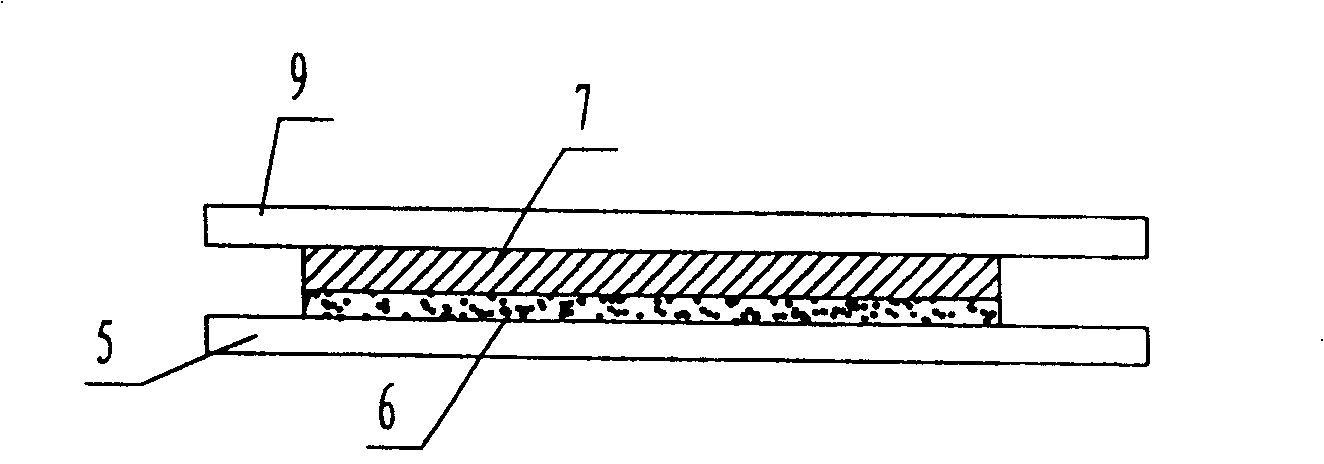

[0016] like figure 2 As shown, the linear temperature sensing element provided with a meltable insulation layer and a pressure-sensitive rubber layer provided by the present invention includes two detection conductors 5, 9 arranged in parallel and a meltable insulation layer arranged in parallel between the detection conductors 5, 9 Layer 6 and pressure sensitive rubber layer 7. The detection conductors 5, 9 can be hollow wires, solid wires or metal fiber braided wires, and the parallel arrangement includes several ways of parallel, winding and coaxial arrangement. like image 3 As shown, when the two detection conductors 5, 9 are arranged in parallel, the meltable insulating layer 6 and the pressure-sensitive rubber layer 7 are arranged in parallel between the detection conductors 5, 9, and are closely attached to each other. like Figure 4 As shown, when the two detection conductors 5, 9 are wound and set, the other can be wound outside one detection conductor, or the tw...

Embodiment 2

[0021] This embodiment is an improvement on the basis of Embodiment 1: that is, a conductive layer arranged in parallel is added between the meltable insulating layer 6 and the pressure-sensitive rubber layer 7 . The conductive layer is made of at least one of materials such as metal wire, non-metal wire, metal sheet, metal foil strip, hollow cylindrical metal sleeve, conductive glue or conductive paint, and can be continuous or intermittent conduction, preferably discontinuous conduction. When materials such as metal wires, non-metal wires, metal sheets, metal foil strips, and hollow cylindrical metal sleeves are used to prepare the intermittent conductive layer, these materials can be used to prefabricate the intermittent conductive layer, or it can be prefabricated. Set up the continuous conduction conductive layer, and then use physical or chemical methods such as mechanical cutting to make it into a discontinuous conduction state. And when using conductive glue or conduc...

Embodiment 3

[0025] This embodiment is an improvement on the basis of Embodiment 1: that is, one of the two parallel detection conductors 5 and 9 uses a memory alloy wire, and the other uses a thermocouple wire. When the linear temperature sensing element is locally heated and reaches the softening (or melting) temperature that can melt the insulating layer 6, the two detection conductors 5 and 9 at the heated part form a temporary thermocouple, which is connected to the conversion at one end of the linear temperature sensing element. The box will send out a fire alarm signal according to the magnitude of the voltage or potential for fire alarm.

[0026]Described thermocouple wire can adopt a kind of in metal materials such as constantan (copper-nickel), nickel silicon, tungsten, chemically pure iron, test copper, molybdenum, chemically pure copper, nickel chromium, nickel, platinum, silver, also Non-metallic materials such as graphite, silicon carbide, boron, and chromium oxide, or semico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com