Liquid state forging die method manufactured automobile air compressor piston and its manufacturing technology

A manufacturing process and air compressor technology, which is applied in the field of manufacturing molds for automobile air compressor pistons and the manufacturing process of using the mold to manufacture automobile air compressor pistons. It can solve the problems of complex inner cavity structure, tissue density, mechanical properties and thermal conductivity. Unsatisfactory, inner cavity core demoulding cannot be carried out, etc., to achieve the effect of improving mechanical properties and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

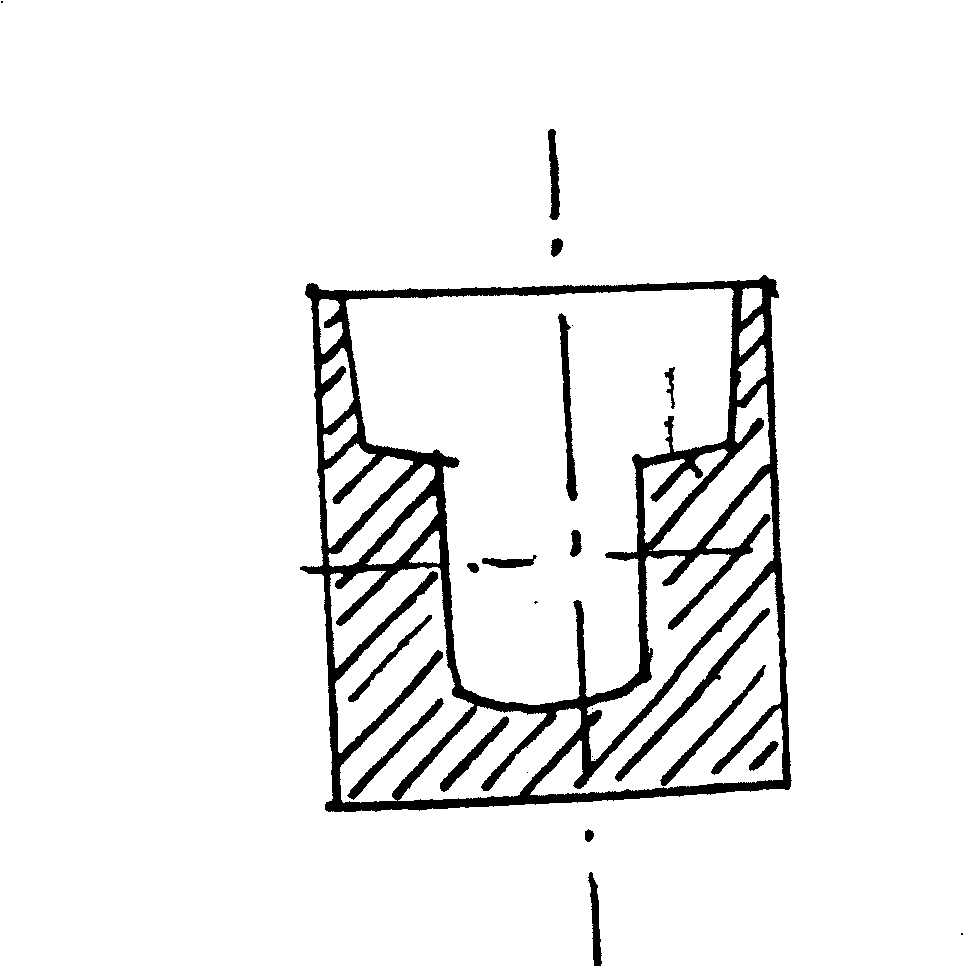

[0017] like figure 1 Shown: a piston of an automobile air compressor, the side of the piston pin seat is flat, and the inner cavity of the skirt is a cavity.

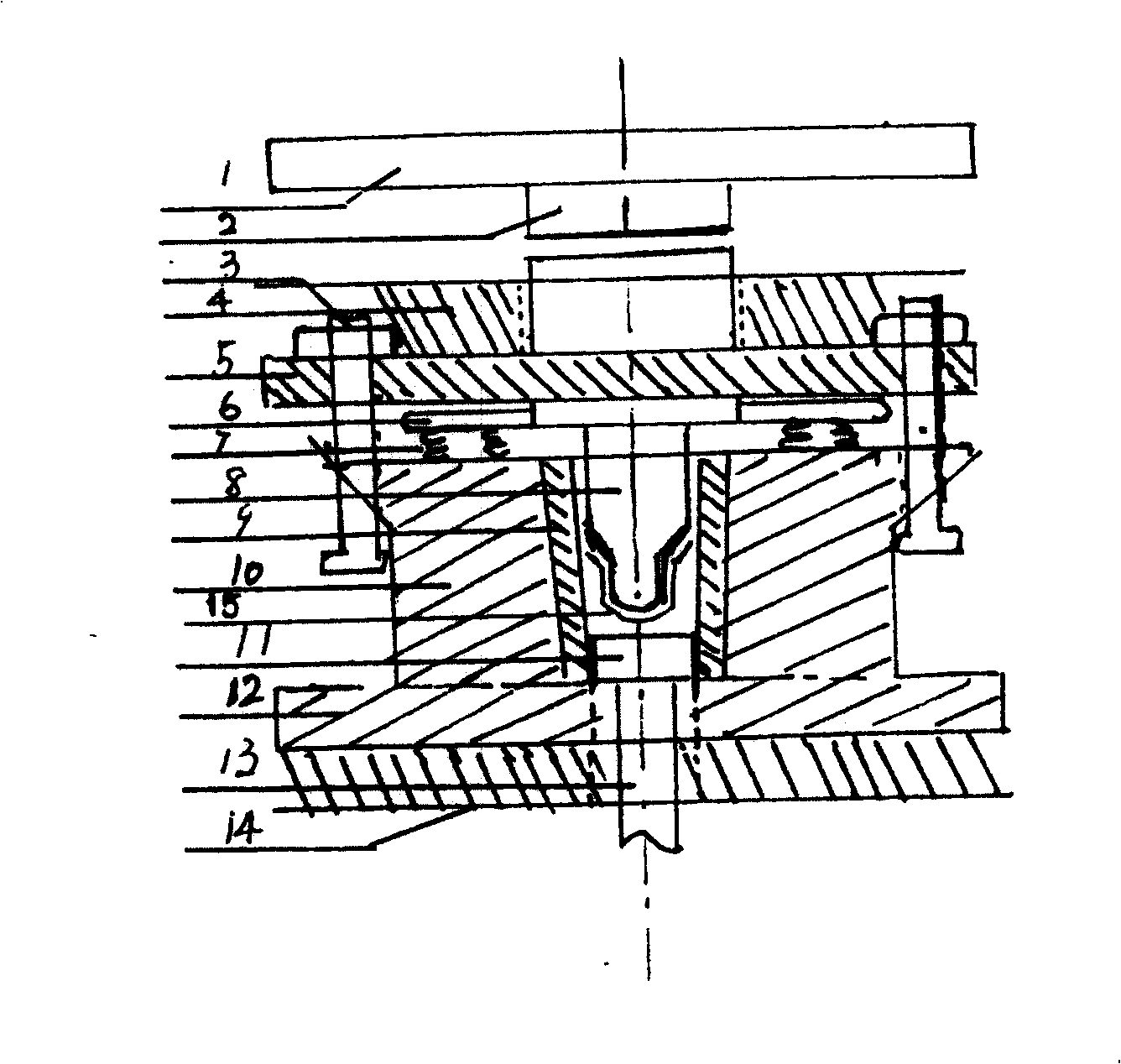

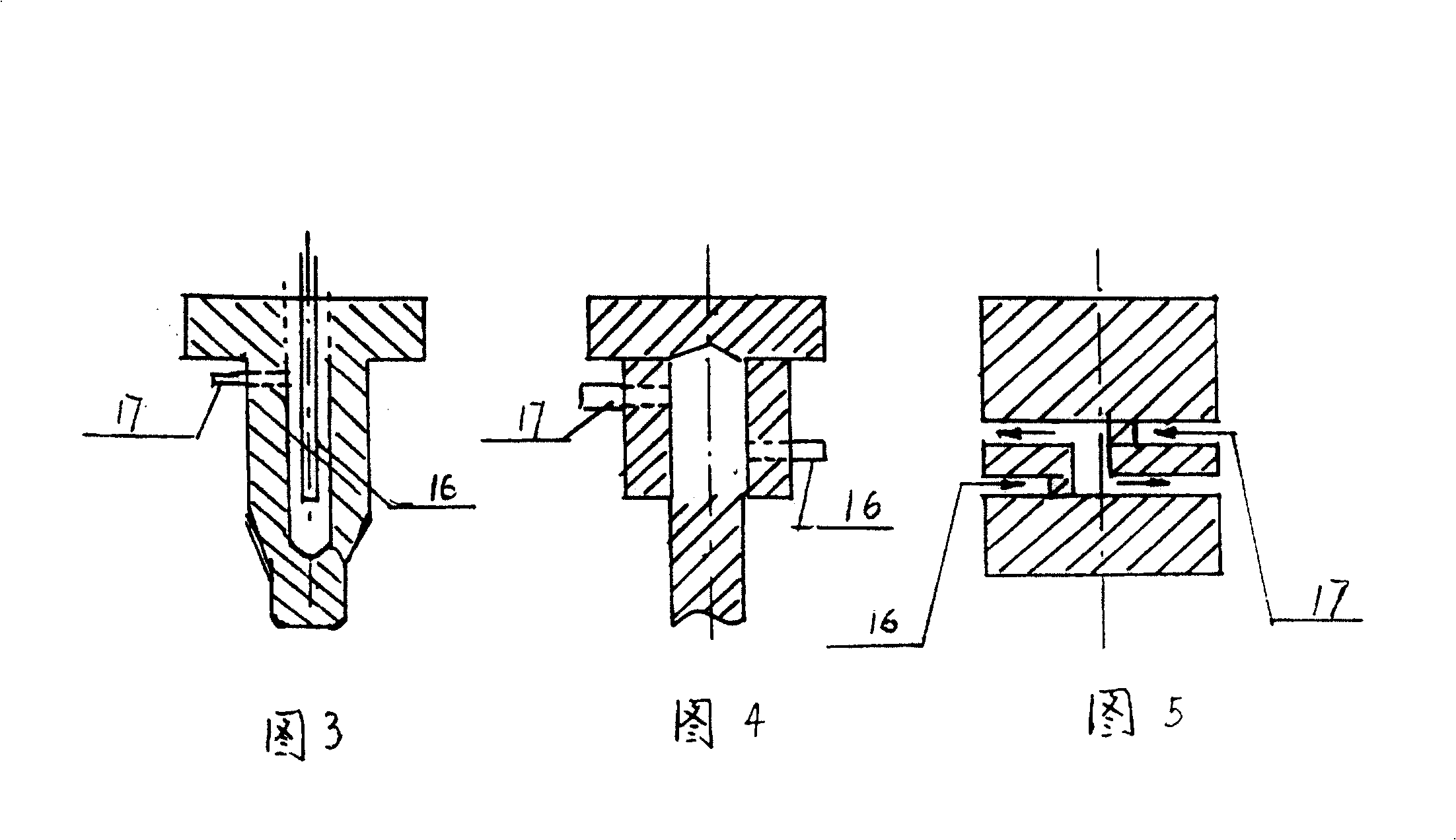

[0018] like figure 2 , 3, 4, and 5 show: 1 is the upper beam, 2 is the main mooring cylinder, 3 is the unloading rod, 4 is the movable scale, 5 is the upper template, 6 is the reset floating platen, 7 is the floating spring, 8 is the core, 9 is the die, and 10 is the Lower mold outer cover 11 is that bottom mold 12 is that lower template 13 is that bottom mold connecting rod 14 is that workbench 15 is unloading ring.

[0019] The mold used for manufacturing the above-mentioned automobile air compressor piston is characterized in that: it is composed of a "convex" shape core that can form the inner cavity of the piston, a discharge ring, a die that can form the external shape of the piston, and a bottom mold: the core is equipped with The unloading ring, and the gap fit between the unloading ring and the core, the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com