Linear temperature sensing element with window on insulating layer

A technology on the insulating layer and the insulating layer, which is applied in the field of online temperature sensing elements, can solve the problems of difficult construction, no change in elasticity, and increased resistance value of itself and wiring points, etc., to achieve easy construction and installation, and good corrosion resistance , good softness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

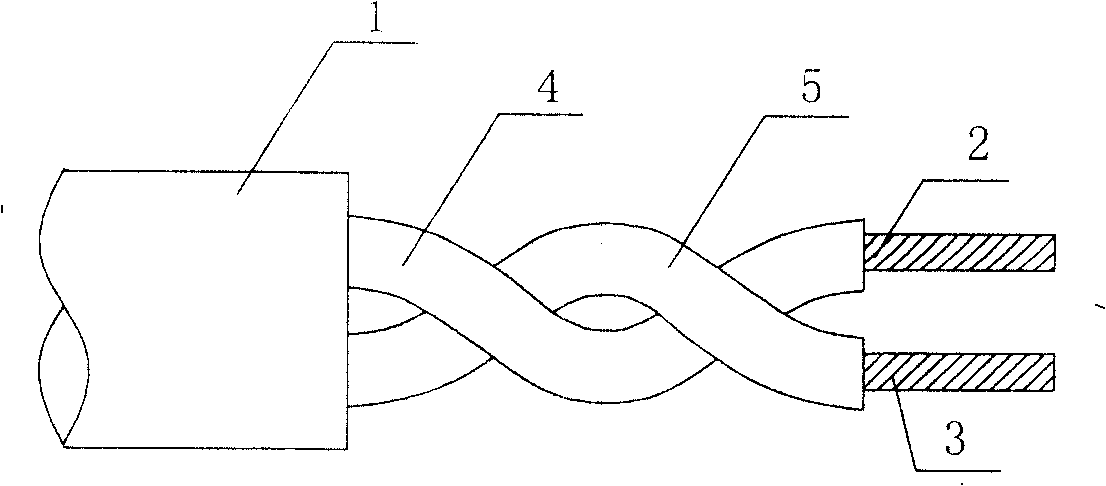

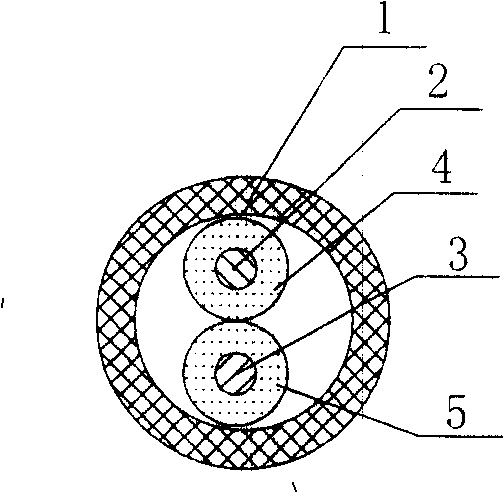

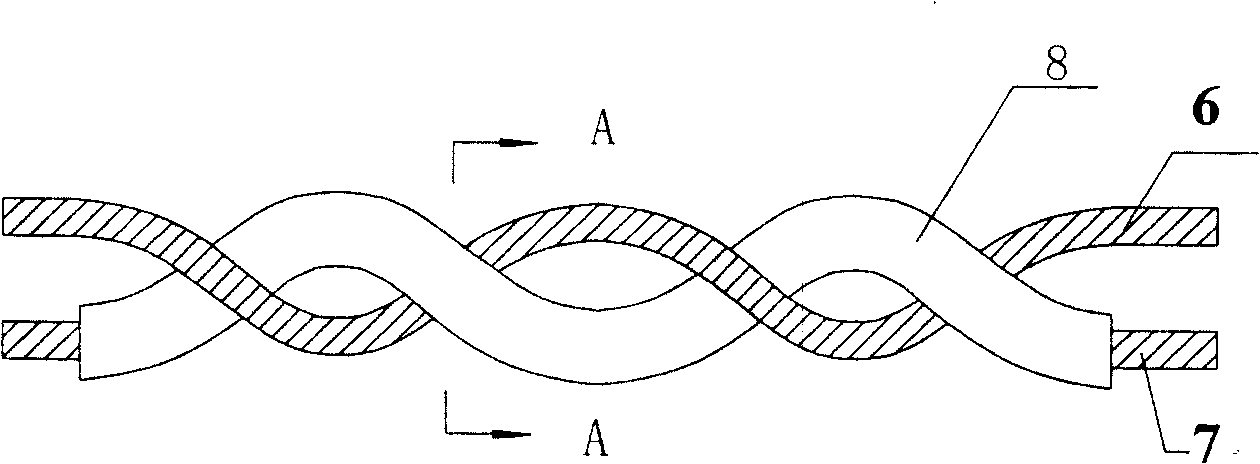

[0018] Such as Figure 3 ~ Figure 4 As shown, the wire-type temperature sensing element provided with windows on the insulating layer provided by the present invention includes an outer sheath, two detection conductors 6, 7 and an insulation layer 8; wherein the two detection conductors 6, 7 are twisted The method is arranged in parallel inside the outer sheath, and at least one of them is a memory alloy wire; the insulating layer 8 is coated on the outer circumferential surface of any one of the two detection conductors 6, 7, and is located on the two detection conductors 6, 7. One or more windows 9 at intervals are formed on the stranded extruding surface between 7 . In the present embodiment, the thickness of the insulating layer 8 is 1 mm, and the detection conductor 7 wrapped inside the insulating layer 8 is a memory alloy wire, and the final temperature Af of the reverse martensitic transformation is set in the range of 50° C. to 100° C. The detection conductor 6 is a c...

Embodiment 2

[0022] This embodiment is an improvement on the basis of the first embodiment: that is, a semiconductor layer is arranged in parallel between the insulating layer 8 and the detection conductor 6 , and the semiconductor layer is coated on the detection conductor 6 in a conventional manner. When the linear temperature sensing element provided with a window on the insulation layer provided by the present invention is heated and reaches the end temperature Af of the reverse martensitic transformation set by the detection conductor 7, the detection conductor 7 will move from the window 9 on the insulation layer 8 to Protrude out so as to contact the semiconductor layer. At this time, the conversion box connected to one end of the linear temperature sensing element will output an alarm signal according to the change value of the electrical parameter (or sampled value) between the detection conductors 6 and 7 .

[0023] The semiconductor layer is selected from one of conductive rubber...

Embodiment 3

[0025] This embodiment is an improvement on the basis of Embodiment 2: that is, the detection conductor 6 adopts a thermocouple wire. Voltage or potential size for fire alarm.

[0026] Described thermocouple wire can adopt a kind of in metal materials such as constantan (copper-nickel), nickel silicon, tungsten, chemically pure iron, test copper, molybdenum, chemically pure copper, nickel chromium, nickel, platinum, silver, also Non-metallic materials such as graphite, silicon carbide, boron, and chromium oxide, or semiconductor materials such as N-type bismuth telluride and P-type bismuth telluride can be used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com