Electrode for piezoelectric ceramic component and its preparation process

A technology of piezoelectric ceramics and components, which is applied in the field of piezoelectric components and its preparation technology, can solve the problems of low pass rate, poor welding reliability, high product cost, etc., and achieve the problems of poor reliability, uniform coating and reduced processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Deposit tin and silver electrode test to ceramic substrate with vapor deposition equipment

[0015] 1. Test conditions: Use TM-800A evaporation equipment to deposit electrode layers on ceramic substrates. The technological parameters of the equipment used are: vacuum degree, 1.5×10 -2 ~3.0×10 -2 Pa; the distance between the evaporation source and the workpiece, 15-30cm; evaporation current: 1000-1600A. Use the above conditions to deposit tin and silver on the ceramic substrate respectively, and see the experimental results for their adhesion:

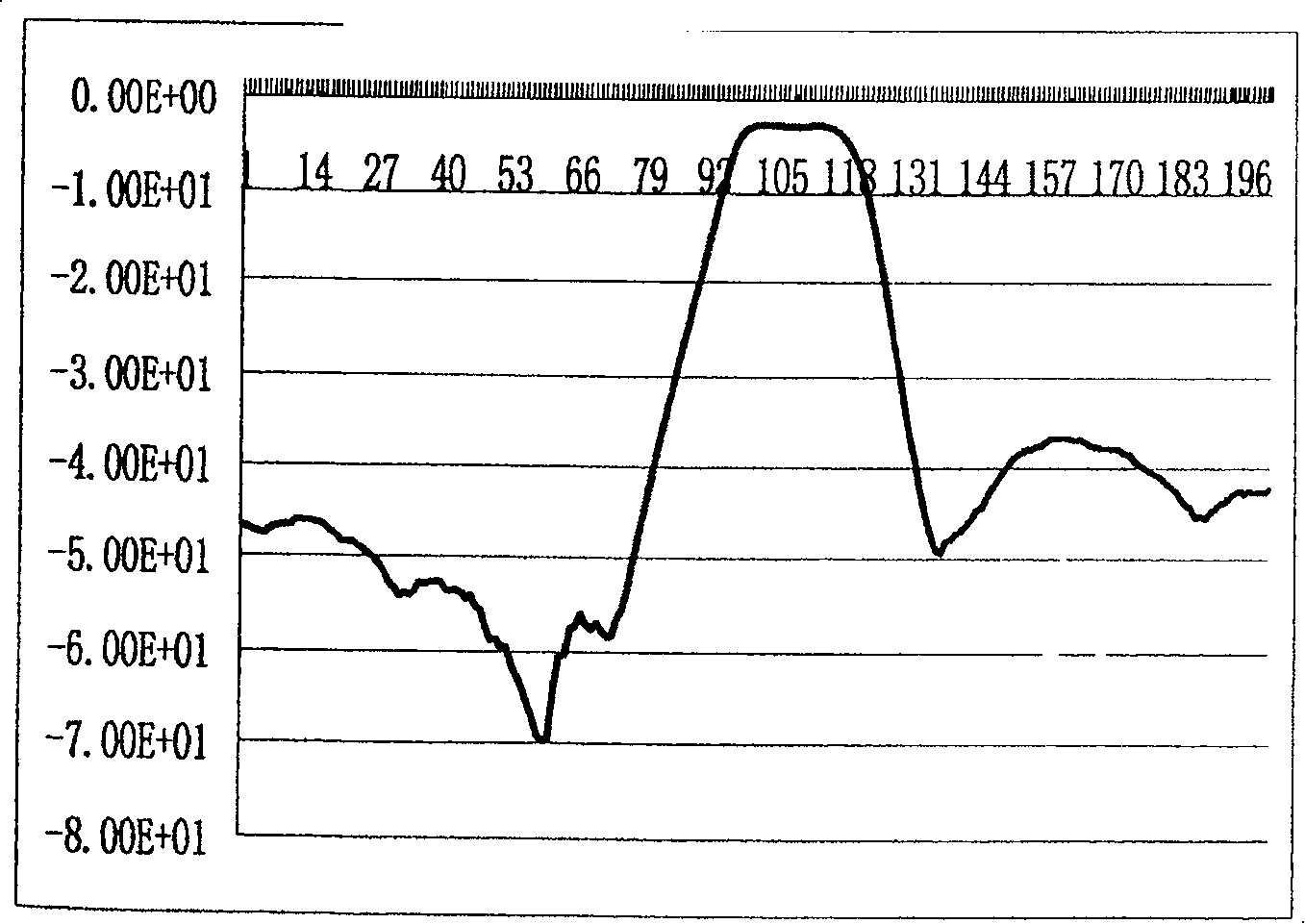

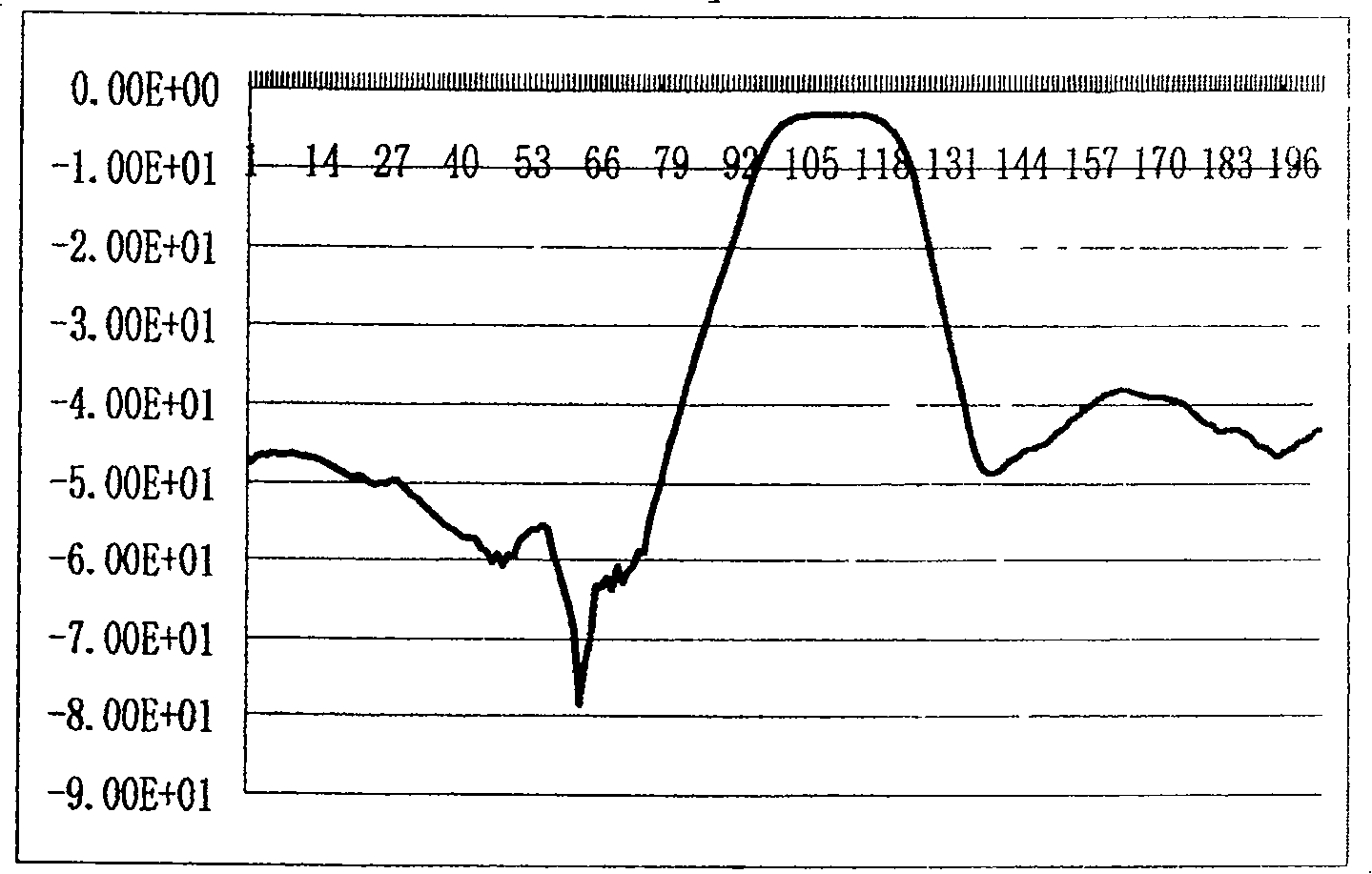

[0016] 2. Experimental results:

[0017] Tin-plated and silver-plated tension comparison: (unit KG solder joint area is 1mm 2 )

[0018]

1

2

3

4

5

6

7

8

9

10

average

Tin plated porcelain

17.9

18.2

19

18.7

15.6

19.8

17.5

20 ...

Embodiment 2

[0027] Embodiment 2: The preparation method of the tin or tin alloy electrode of the piezoelectric ceramic component of the present invention comprises the following steps:

[0028] ① Manufacture inner layer copper electrodes of piezoelectric ceramic components;

[0029] ②Use the vacuum evaporation method, use the TM-800A vacuum evaporation equipment, and the vacuum degree is 1.5×10 -2 3×10 -2 pa, the distance between the evaporation source and the workpiece is 15-30cm, and the evaporation current is 1000-1600A, deposit metal tin or tin alloy outer electrode on the piezoelectric ceramic inner layer copper electrode, so that the thickness of the tin or tin alloy coating is 0.5~5um;

[0030] ③ When aging the polarized ceramic sheet, the tin or tin alloy electrode is treated with an anti-oxidation process;

[0031] ④ Assembly of piezoelectric ceramic components by chip flip-chip immersion tin welding process;

[0032] ⑤ Inspection and storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com