Device and method for reducing concentration of nitrogen oxide in discharged tail gas of explosive powder production line

A nitrogen oxide and production line technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high raw material prices, cumbersome process operations, and expensive system operation costs, achieve closed-loop utilization of materials, reduce nitric acid, etc. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

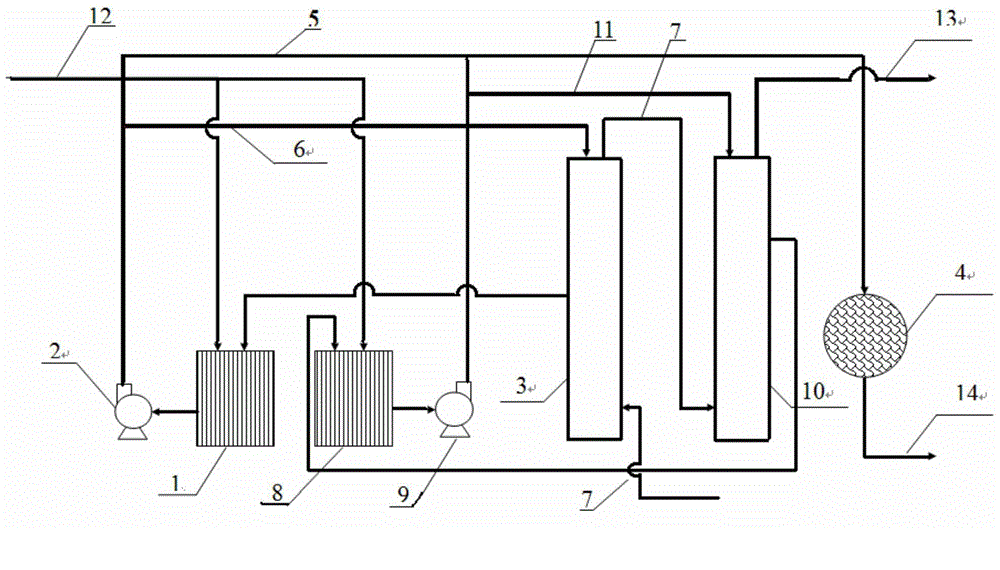

[0036] This embodiment is a method for reducing the concentration of nitrogen oxides in the exhaust gas from a propellant and explosive production line. The processing device used includes two circulation tanks, two circulation pumps, two tail gas decomposition towers and waste acid tank 4, as well as acid replacement pipelines and sulfuric acid circulation pipelines. There are two inlets at the upper end of the first circulation tank 1, the first inlet is communicated with the concentrated sulfuric acid pipeline 12, and the concentrated sulfuric acid comes from the sulfuric acid concentration process, and the concentration of the concentrated sulfuric acid is 93%; the second inlet at the upper end of the first circulation tank 1 An inlet is connected with the first tail gas decomposition tower 3 by pipeline, so that the sulfuric acid injected into the first tail gas decomposition tower 3 can return to the first circulation tank 1; the lower end of the first circulation tank ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com