Anti-discolouring technology for copper alloy coin blank and special preparation for anti-discolouring thereof

A copper alloy, anti-discoloration technology, applied in the direction of metal material coating process, can solve problems such as discoloration, and achieve the effect of bright surface, remarkable anti-discoloration performance, and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

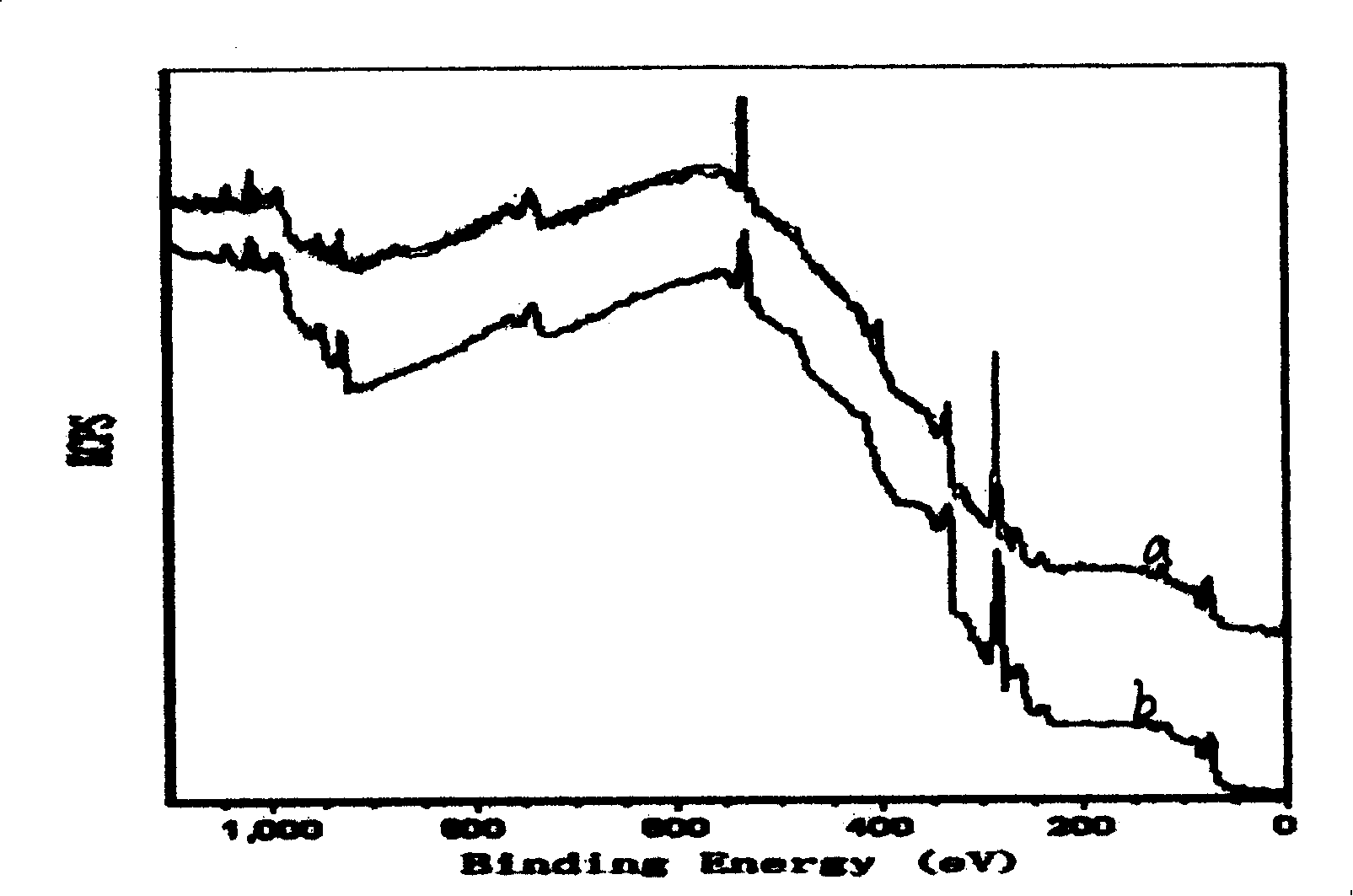

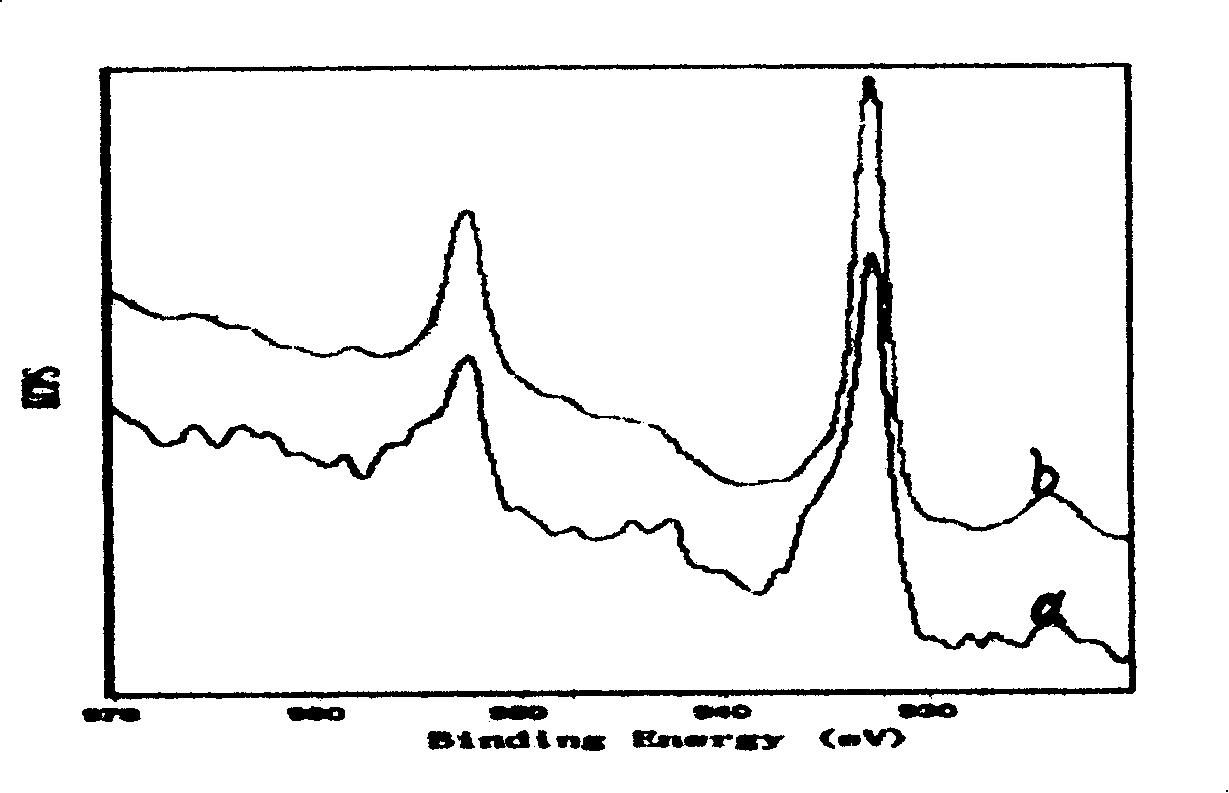

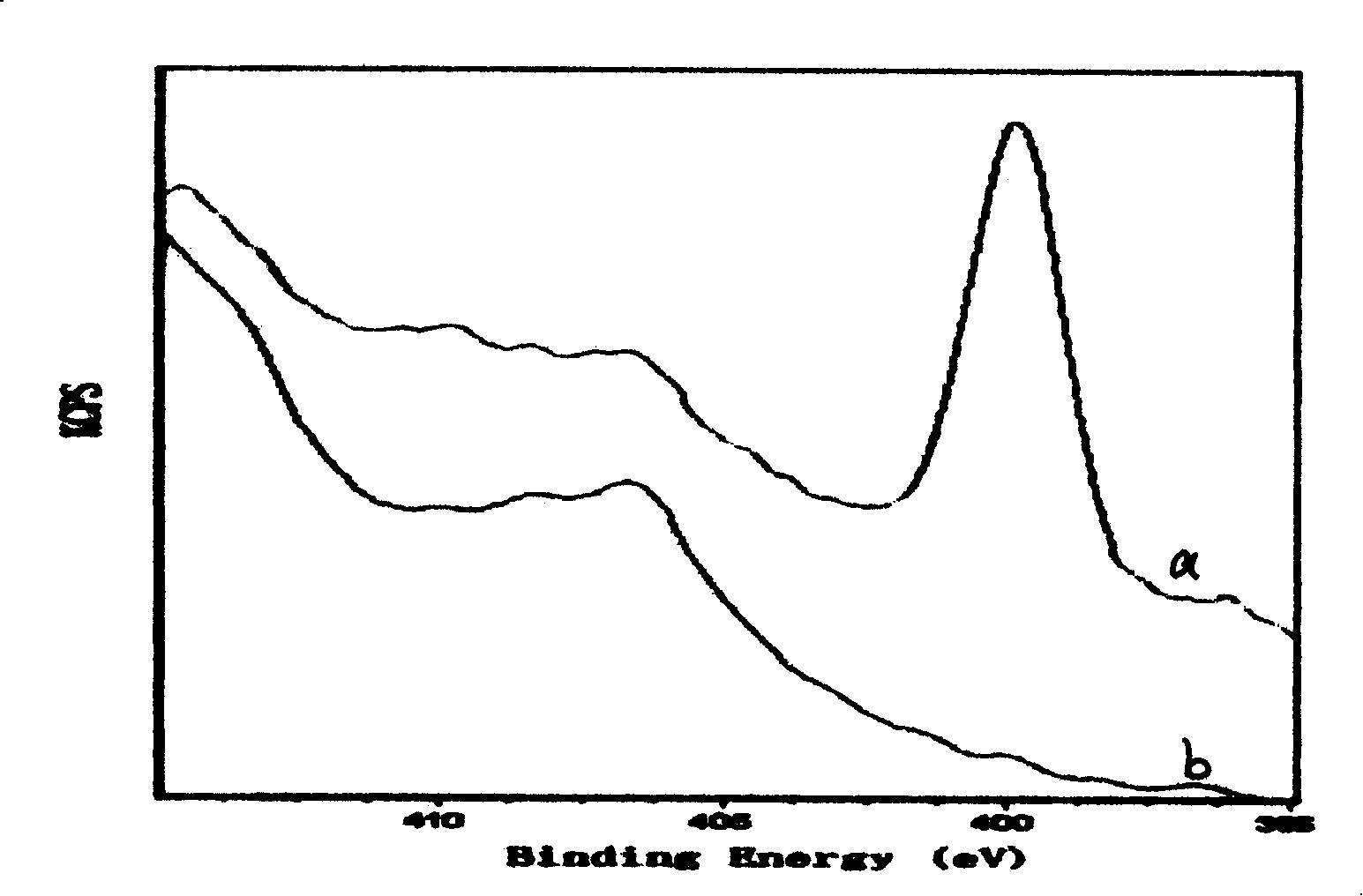

Image

Examples

Embodiment 1

[0061] Copper alloy coin blank cake anti-discoloration process of the present invention:

[0062] Artificial sweat accelerated corrosion test--QJ / SYB07.02-1997

[0063] 1. Annealing: annealing the copper alloy coin blank to make it reach the required hardness index;

[0064] 2. Pickling: Remove oxides on the surface of the copper alloy coin blank cake with a mixed solution of sulfuric acid and phosphoric acid for 25 minutes;

[0065] 3. Rinsing 1: Rinse the copper alloy coin blank cake for the first time with clean water for 8 minutes;

[0066] 4. Polishing: use SC-880, which is easy to clean, to polish and smooth the copper alloy coin blank cake, and the time is 26 minutes;

[0067] 5. Rinse 2: Rinse the copper alloy coin blank cake for the second time with clean water for 9 minutes;

[0068] 6. Anti-corrosion treatment: immerse the surface clean, completely non-oxidized copper alloy coin blank cake in the anti-tarnish preparation for 6 minutes, the copper alloy coin blank...

Embodiment 2

[0083] Copper alloy coin blank cake anti-discoloration process of the present invention:

[0084] Annealing → Pickling → Rinsing 1 → Polishing → Rinsing 2 → Anti-corrosion treatment → Rinsing 3 → Drying

[0085] After the copper alloy blank cake is annealed to reach the required hardness index, the surface oxide is washed away by acid solution. After leveling, the surface is clean and the metal surface is free of oxidation, and then immersed in anti-tarnish solvent, a chemical reaction occurs rapidly, and an organic conversion film is formed on the surface.

[0086] The anti-tarnishing preparation can adopt commercially available products.

Embodiment 3

[0088] The anti-discoloration process of the copper alloy coin blank cake of the present invention is the same as that in Embodiment 1.

[0089] Its anti-tarnish preparation is composed of the following ingredients according to the proportion:

[0090] Benzotriazole: 3g / l

[0091] Nonylphenol polyoxyethylene lauryl ether: 5g / l

[0092] Benzoic acid: 1g / l

[0093] Sodium phosphate: 10g / l

[0094] The preparation method of above-mentioned anti-tarnishing preparation is:

[0095] 1. First heat deionized water to 45 degrees Celsius, add nonylphenol polyoxyethylene lauryl ether 5g / l according to the above composition ratio, and add benzotriazole 3g / l after it is completely dissolved;

[0096] 2. Add 1 g / l of benzoic acid according to the above ratio;

[0097] 3. Add sodium phosphate 10g / l according to the above ratio;

[0098] 4. Stir well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com