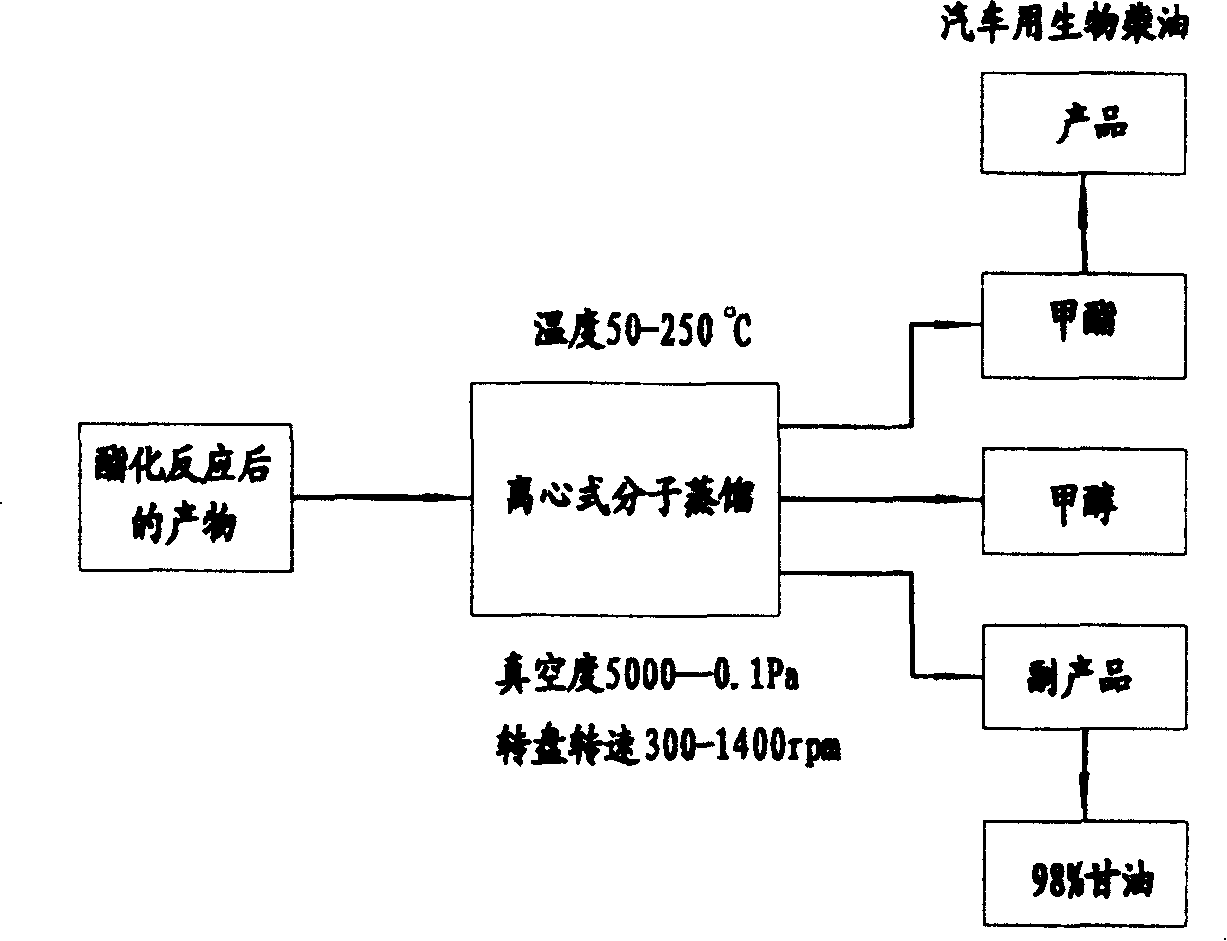

Centrifugal molecular distillating process of producing biological diesel for automobile

A molecular distillation and biodiesel technology, applied in the fields of hydrocarbon distillation, biological raw materials, biofuels, etc., can solve the problems of increasing equipment cost and processing cost, not being able to use high-end automobiles, reducing output rate, etc., and achieving evaporation rate and separation efficiency. The effect of reducing the risk of thermal decomposition and saving water treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

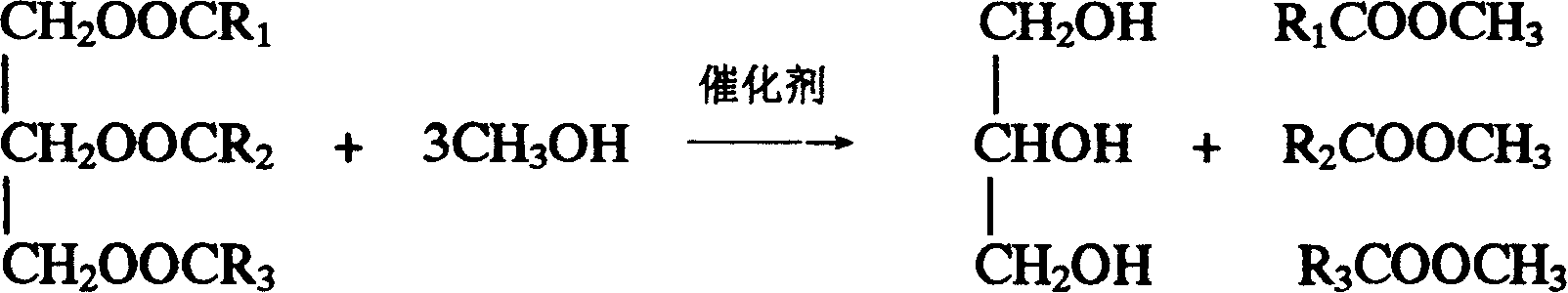

Method used

Image

Examples

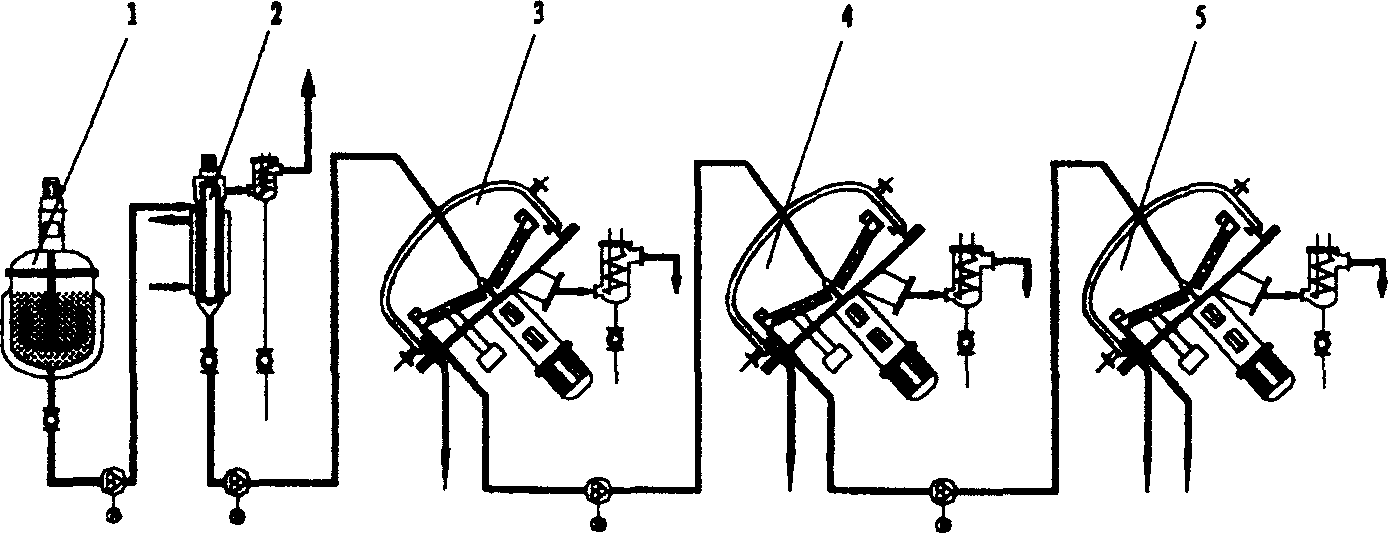

Embodiment 1

[0028] Adopt coconut oil and methanol to carry out esterification, the molar ratio of coconut oil and methanol is 1:6. Such as figure 2 As shown, 800ml of the intermediate product after the reaction enters the buffer tank 1, and then enters the degassing column 2. The degassing temperature is 60°C and the vacuum degree is 5000Pa; after degassing, the product enters the first-stage centrifugal molecular still 3 to separate the esterification reaction Excess methanol, the temperature is 80°C, the vacuum is 1000Pa, and the rotating speed of the turntable is 1200rpm; then it enters the second stage centrifugal molecular still 4 to separate glycerin, the temperature is 120°C, the vacuum is 100Pa, and the rotating speed of the turntable is 1400rpm; finally enters The third-stage molecular distillation tower 5 separates 420 grams of methyl ester, the temperature is 180° C., the vacuum degree is 0.1 Pa, the rotation speed of the turntable is 1200 rpm, and the remaining impurities are...

Embodiment 2

[0030] The esterification reaction is carried out by using tallow and ethanol, and the molar ratio of tallow and ethanol is 1:6.5. Such as figure 2 As shown, after the reaction, 750ml of the intermediate product enters the buffer tank 1, and then enters the degassing column 2. The degassing temperature is 100°C and the vacuum degree is 1000Pa; after degassing, the product enters the first-stage centrifugal molecular still 3 to separate the remaining esterification reaction. ethanol at a temperature of 150°C, a vacuum of 100Pa, and a rotating speed of 600rpm; then enter the second-stage centrifugal molecular still 4 to separate glycerol at a temperature of 250°C, a vacuum of 10Pa, and a rotating speed of 800rpm; The three-stage centrifugal molecular distillation tower 5 separates 405 grams of ethyl ester, the temperature is 250° C., the vacuum degree is 1 Pa, the rotary speed is 800 rpm, and the remaining impurities are discharged. After testing, the purity of the prepared me...

Embodiment 3

[0032] Rapeseed oil and methanol are used for the esterification reaction, and the molar ratio of rapeseed oil to methanol is 1:7. Such as figure 2As shown, 700ml of the intermediate product after the reaction enters the buffer tank 1, and then enters the degassing column 2. The degassing temperature is 80°C and the vacuum degree is 3000Pa; the degassed product enters the first-stage centrifugal molecular still 3 to separate the esterification reaction The remaining methanol has a temperature of 110°C, a vacuum of 500Pa, and a turntable speed of 1000rpm; then enters the second-stage centrifugal molecular still 4 to separate glycerin, a temperature of 180°C, a vacuum of 50Pa, and a turntable speed of 1200rpm; finally enters The third-stage centrifugal molecular distillation tower 5 separates 370 grams of methyl esters, the temperature is 230° C., the vacuum degree is 25 Pa, the rotation speed of the rotating disk is 600 rpm, and the remaining impurities are discharged. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com