High pressure vacuum electronic beam welding method for stator ring of air compressor of gas steam turine

A technology of vacuum electron beam welding and vacuum electron beam, which is applied in the direction of electron beam welding equipment, welding equipment, welding equipment, etc., can solve the difficulty of making breakthroughs in the welding and manufacturing technology of key components of gas turbines, and the difficulty of accurately controlling the welding sequence of pre-shrinkage margins , Welding deformation and welding cracks have a great influence, and achieve the effects of shortening the production cycle, low power, and long working distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

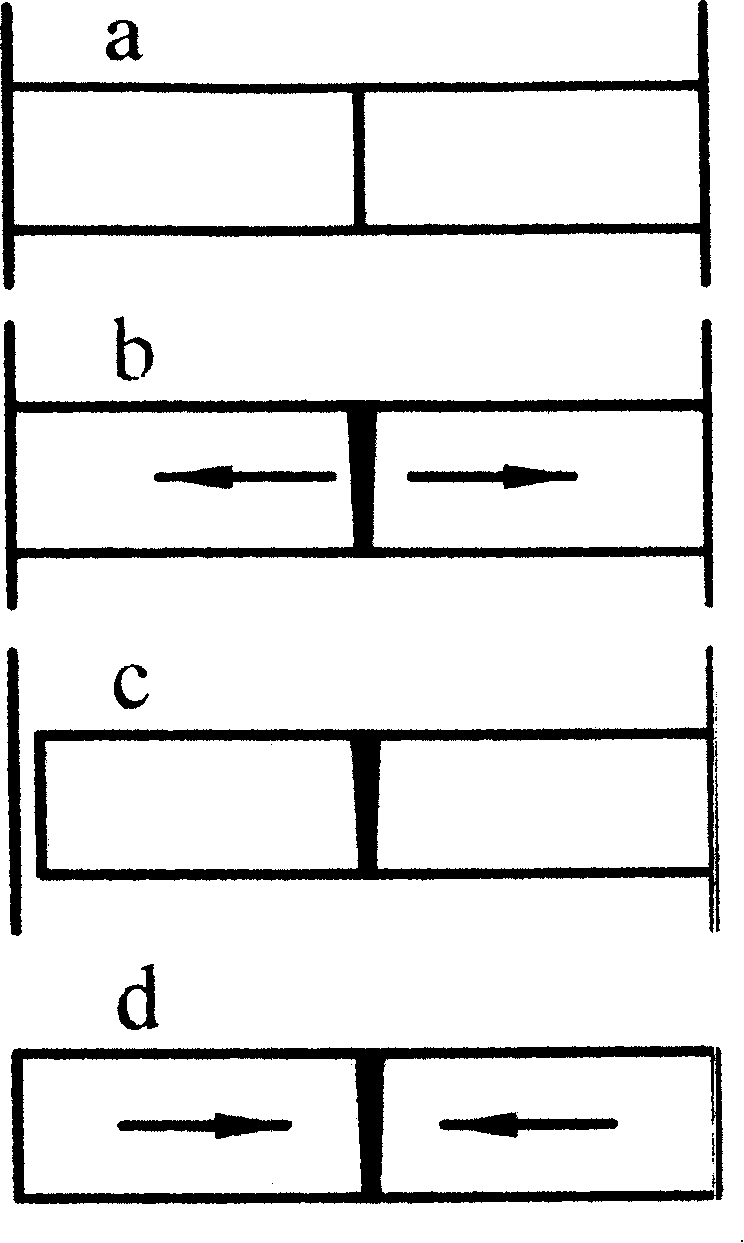

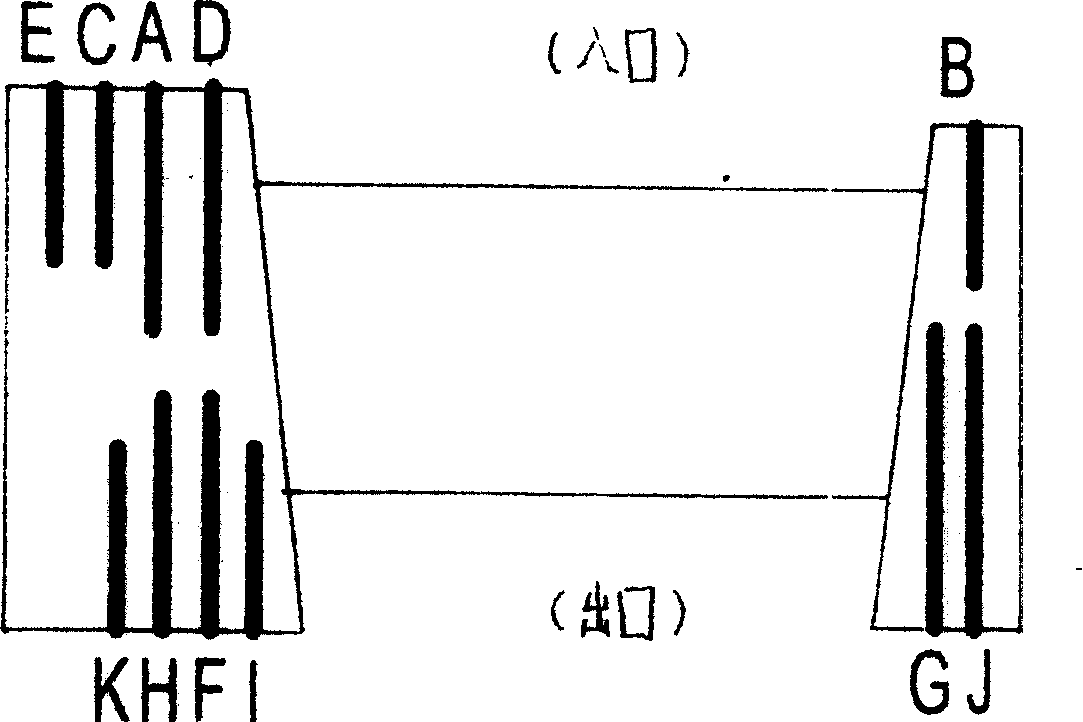

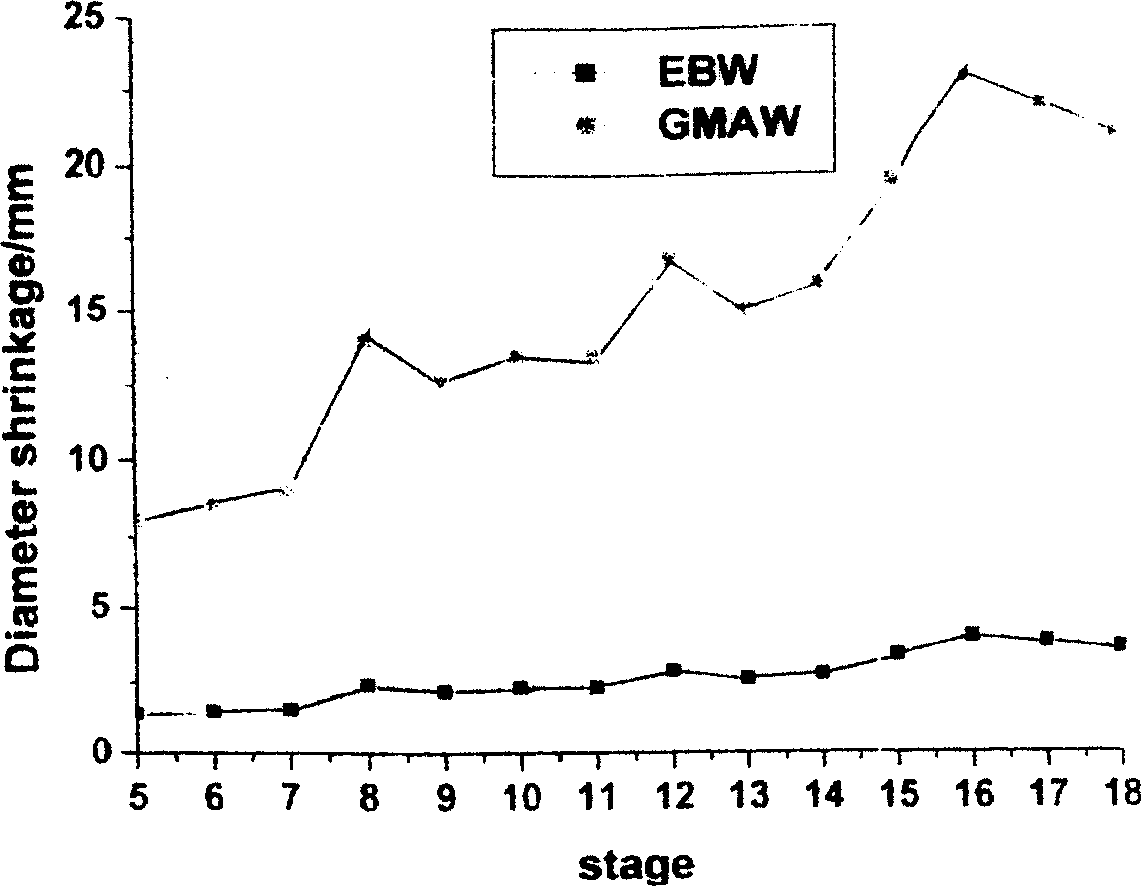

[0024] refer to Figure 1-Figure 6 , Welding deformation and crack analysis: The overall structure of this product is simple, but the rigidity is poor, the size is large, and welding deformation is the main problem. Deformation must be controlled from the aspects of pre-setting welding shrinkage, strengthening rigid fixation, reasonable selection of welding specifications and selection of reasonable assembly welding sequence. The first is the effect of welding stress on deformation. Stresses are generated during the heating and cooling that occurs during welding. Internal welding stresses are those that remain at the weld of the part after cooling to room temperature. Welding stresses or internal welding stresses can lead to the formation of various cracks (hot cracks, shrinkage cracks, etc.), which are the main cause of component deformation. figure 1 It is a schematic diagram of the formation of transverse shrinkage and shrinkage stress in welding. In the figure, a) repres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com