Electromagnetic lens adopting miniaturized frequency selective surface

A technology of frequency selective surface and electromagnetic lens, applied in the direction of electrical components, antennas, etc., can solve the problems of small unit size, large thickness, small lens volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

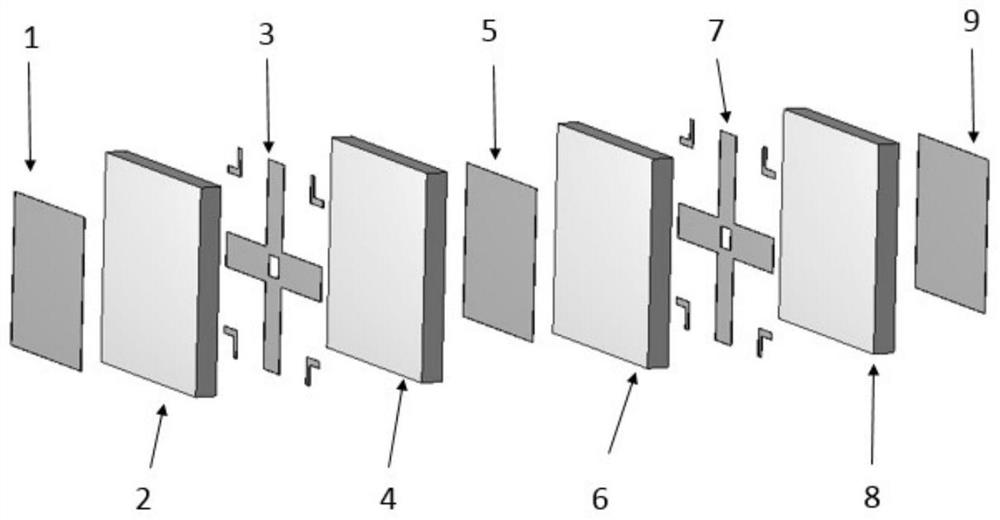

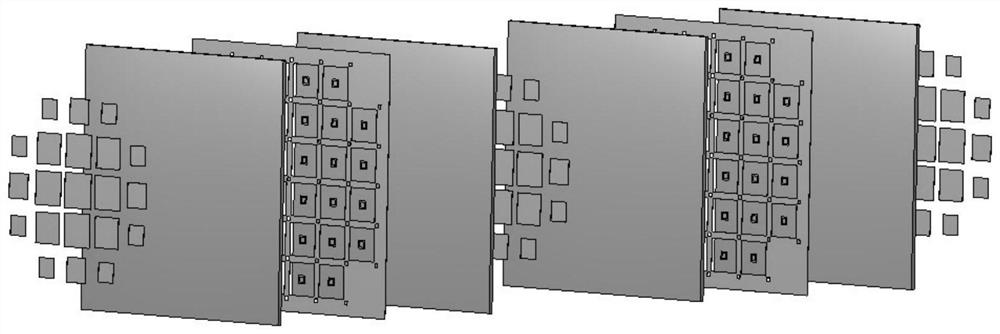

[0038] An electromagnetic lens using a miniaturized frequency selective surface, including several antenna units arranged in a matrix in a circle, the central position antenna unit and the edge position antenna unit are delayed by one wavelength, and the antenna unit includes sequentially the first One unit patch layer 1, first unit dielectric layer 2, first unit grid layer 3, second unit dielectric layer 4, second unit patch layer 5, third unit dielectric layer 6, second unit grid layer 7. The fourth unit dielectric layer 8 and the third unit patch layer 9, the first unit patch layer 1, the second unit patch layer 5 and the third unit patch layer 9 are identical metal layers, so The first unit grid layer 3 and the second unit grid layer 7 are identical, the first unit grid layer 3 and the second unit grid layer 7 are metal crosses, and a square gap is hollowed out in the center, and the cross Four L-shaped metal strips are arranged on the four corners. When arranged accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com