Multilayer co-extrusion transfusion film and manufacturing method thereof

A technology of multi-layer co-extrusion and infusion film, which is applied in the field of multi-layer co-extrusion film and its manufacturing, can solve the problems such as the sanitation index of down-blowing water cooling cannot meet the national standard requirements, the control of microbial limit is not good, and the sanitation index cannot pass, etc. , achieve wide drug compatibility, reduce dispensing time, and keep physical properties from falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

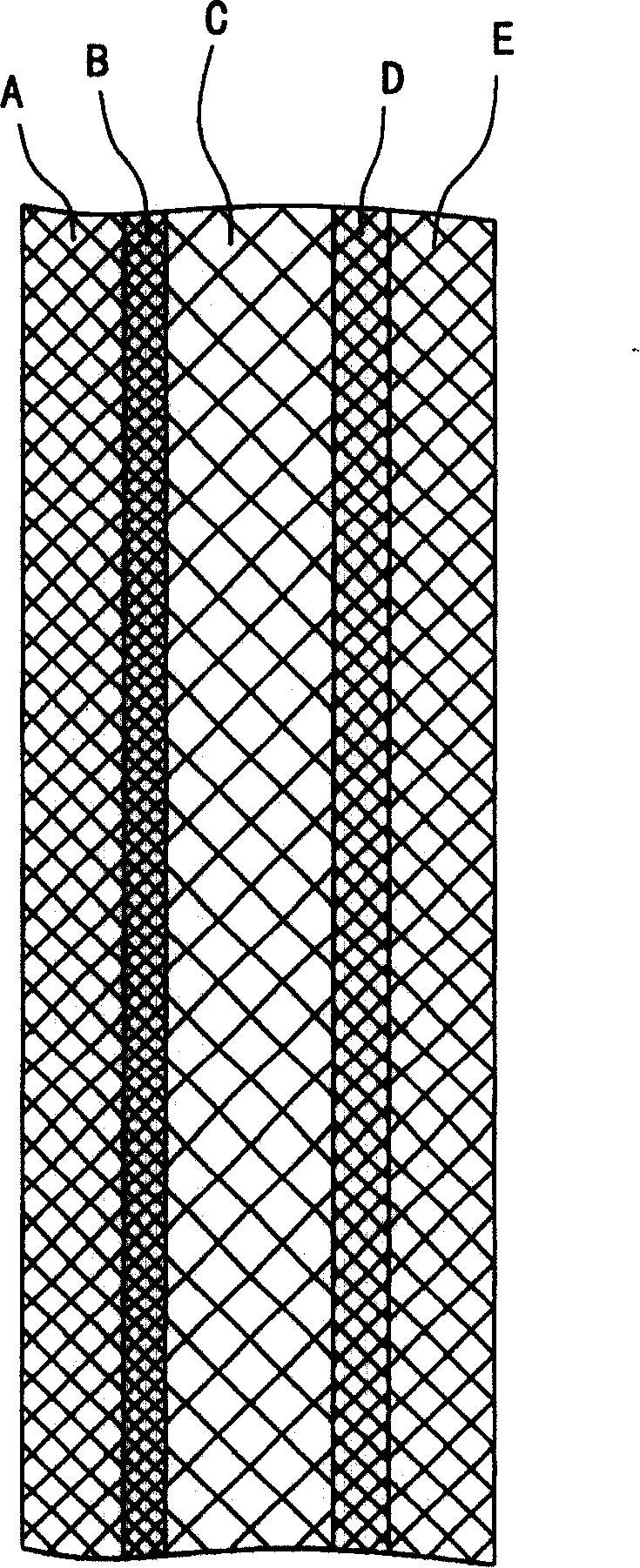

[0035] Such as figure 1 As shown, it reflects the arrangement of the layers of the multilayer co-extruded infusion film of the present invention. It can be seen from the figure that it has a five-layer structure in terms of material composition. The first to fifth layers are heat-sealed inner layer A, adhesive layer B, core layer C, adhesive layer D, and weathering layer E in sequence.

[0036] Choose a melt index of 2.0~15g / 10min and a density of 0.89~0.9g / cm 3 The mixed resin composed of polypropylene and SEBS thermoplastic elastic copolymer, the melt index is 1.5~5g / 10min, the density is 0.89~0.9g / cm 3 Propylene-ethylene copolymer with a melt index of 1~5g / 10min and a density of 0.89~0.92g / cm 3 Propylene-ethylene / a-olefin copolymer elastomer with a melt index of 1.5~5g / 10min and a density of 0.9~0.93g / cm 3 Ethylene methacrylate polymer with a melt index of 4~10g / 10min and a density of 1.1~1.3g / cm 3 The flexible resin polyethylene terephthalate, as the raw material for the manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com