Preparation method of self-repairing electrode material based on supramolecular double-network structure

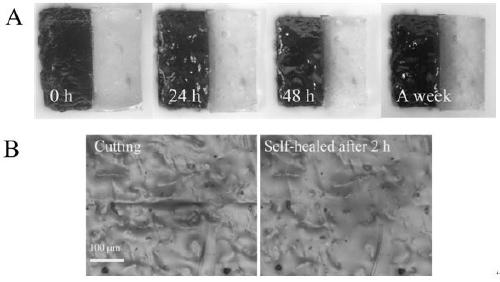

A technology of network structure and electrode material, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, circuits, etc., can solve the problems of limited number of self-repair cycles, hindering the conductivity of conductive paths, and reducing the conductivity. Achieve the effects of simple and efficient synthesis method, recovery of electrical properties, and controllable material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

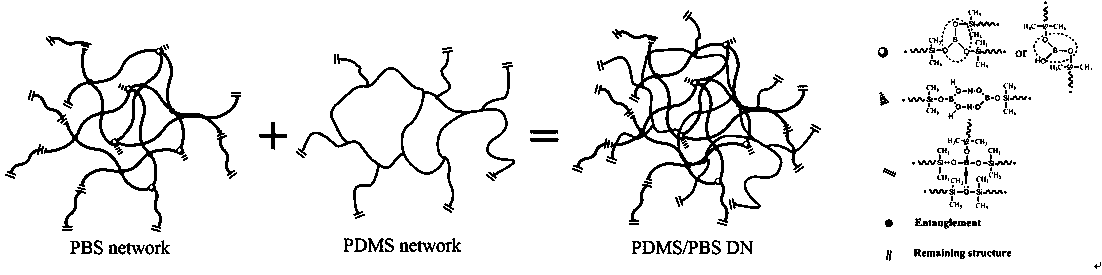

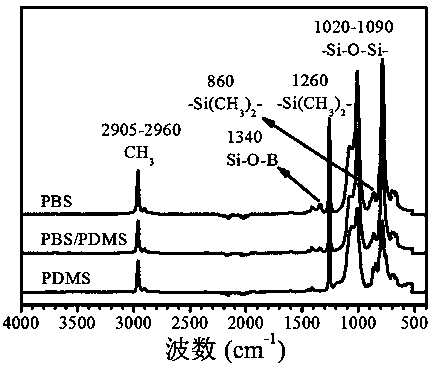

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh boric acid and hydroxyl-terminated polydimethylsiloxane, add them into the reaction flask at a mass ratio of 1:1, and stir thoroughly to completely disperse the boric acid to obtain a boric acid mixture;

[0030] (2) Weigh 0.2 g of commercial silica gel cross-linking agent and 2 g of commercial silica gel into the reaction bottle, and stir thoroughly to completely disperse the cross-linking agent to obtain a commercial silica gel mixture;

[0031] (3) While stirring, add the commercial silica gel mixture obtained in step (2) to the boric acid mixture obtained in step (1) dropwise at a ratio of 10 wt%, and react in a vacuum oven at 120°C for 24 h. After the reaction, the reaction bottle was cooled to room temperature to obtain a colorless and transparent solid, which was an elastomer;

[0032] (4) Hydrophobizing the substrate, that is, dissolving 1H,1H,2H,2H-perfluorooctyltrichlorosilane in n-hexane to make a 2-5mol / mL solution, soaking the substrate for 1 hour...

Embodiment 2

[0034] Example 2: Same as Example 1, the molecular weight of polydimethylsiloxane in step (1) is 85 kg / mol.

Embodiment 3

[0035] Embodiment 3: The stoichiometric ratio of boric acid to polydimethylsiloxane in step (1) is 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com