Micro electromechanic safe coded lock encoded method for processing gear wheel, and process unit

A technology for encoding gears and processing devices, which is applied in transportation and packaging, wheels, metal extrusion dies, etc., can solve the problems of long process cycle, large investment in LIGA technology equipment, and difficulty in reducing component size, achieving short process cycle, Excellent structural strength and reduced component size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

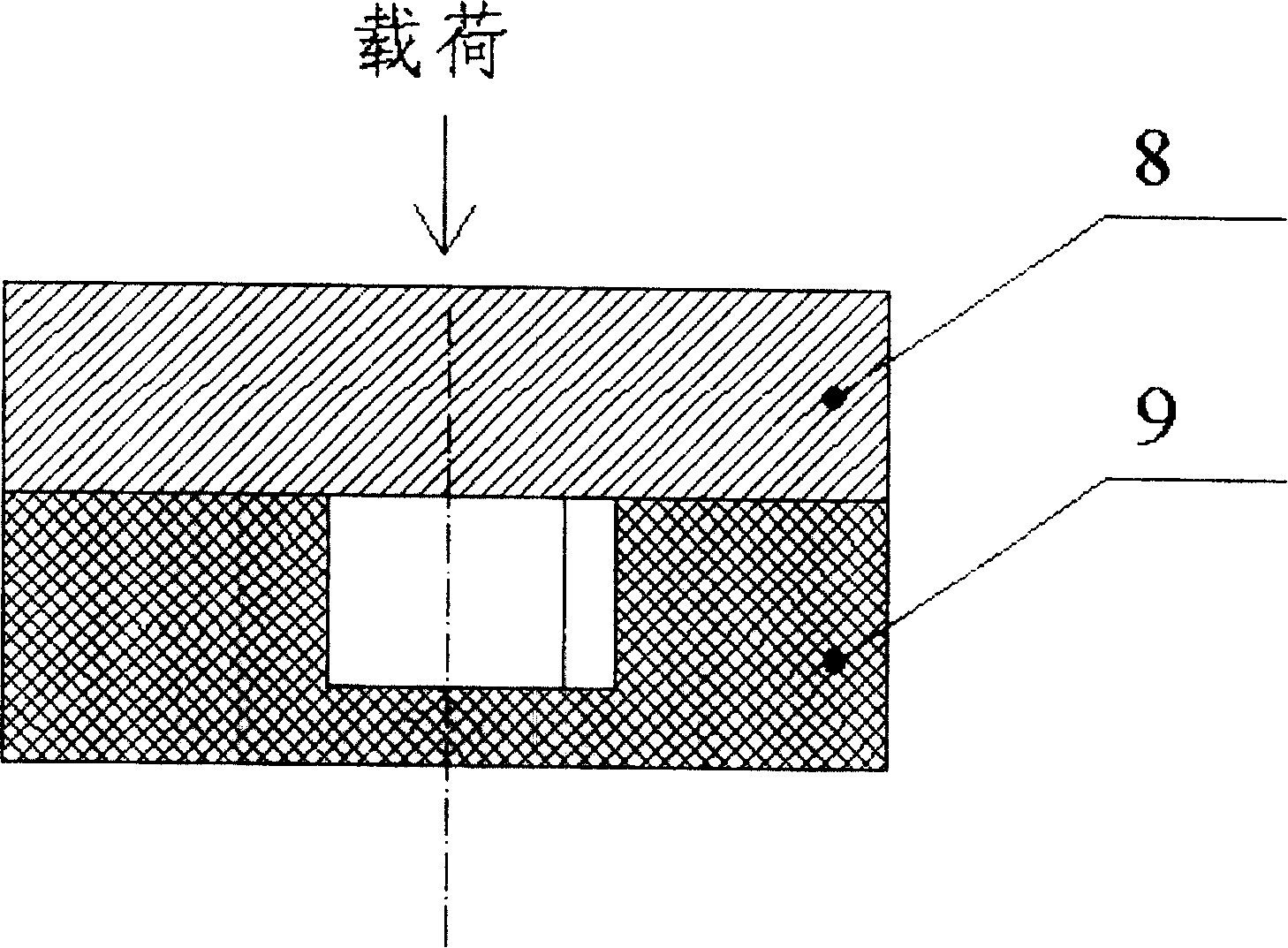

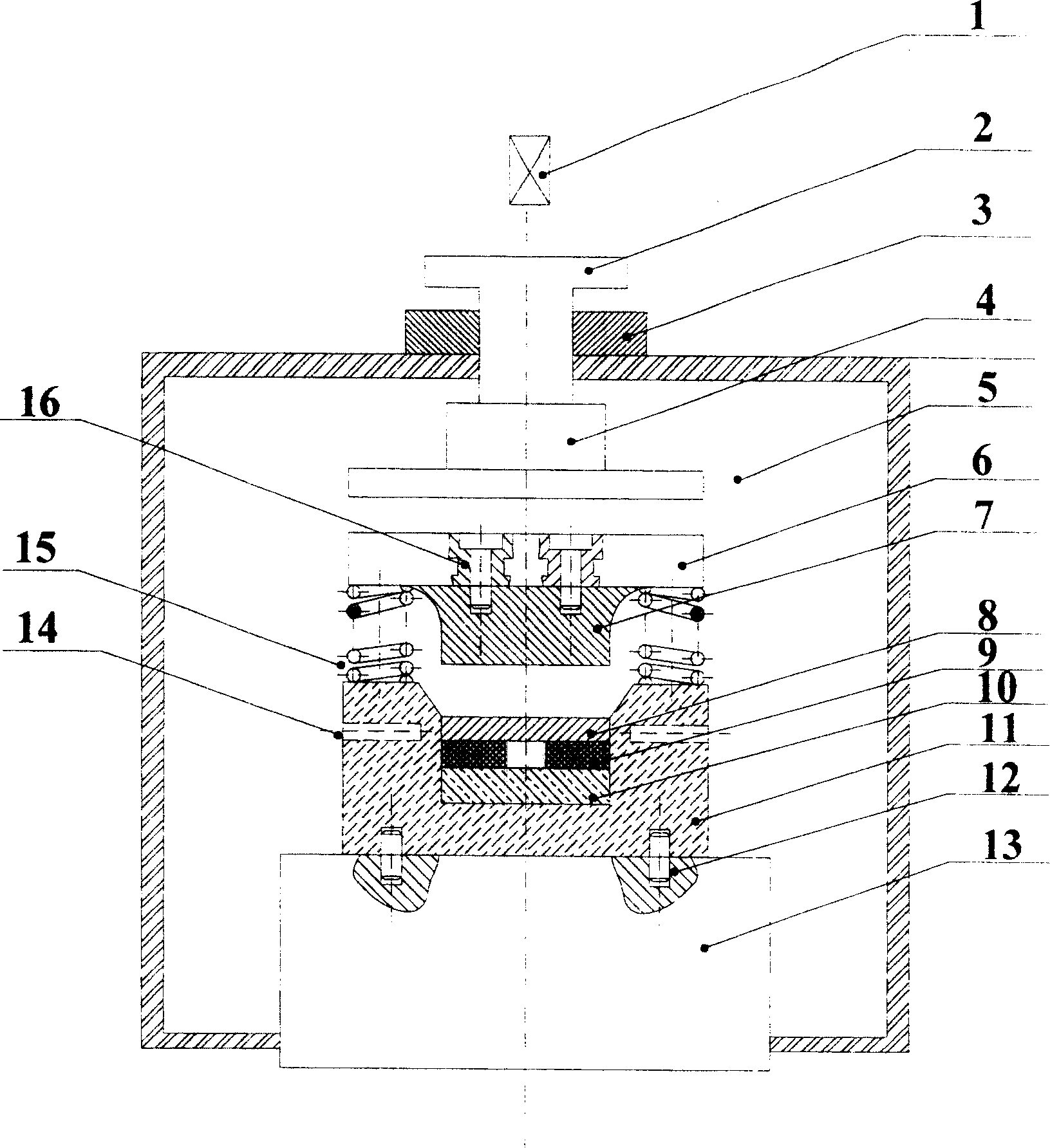

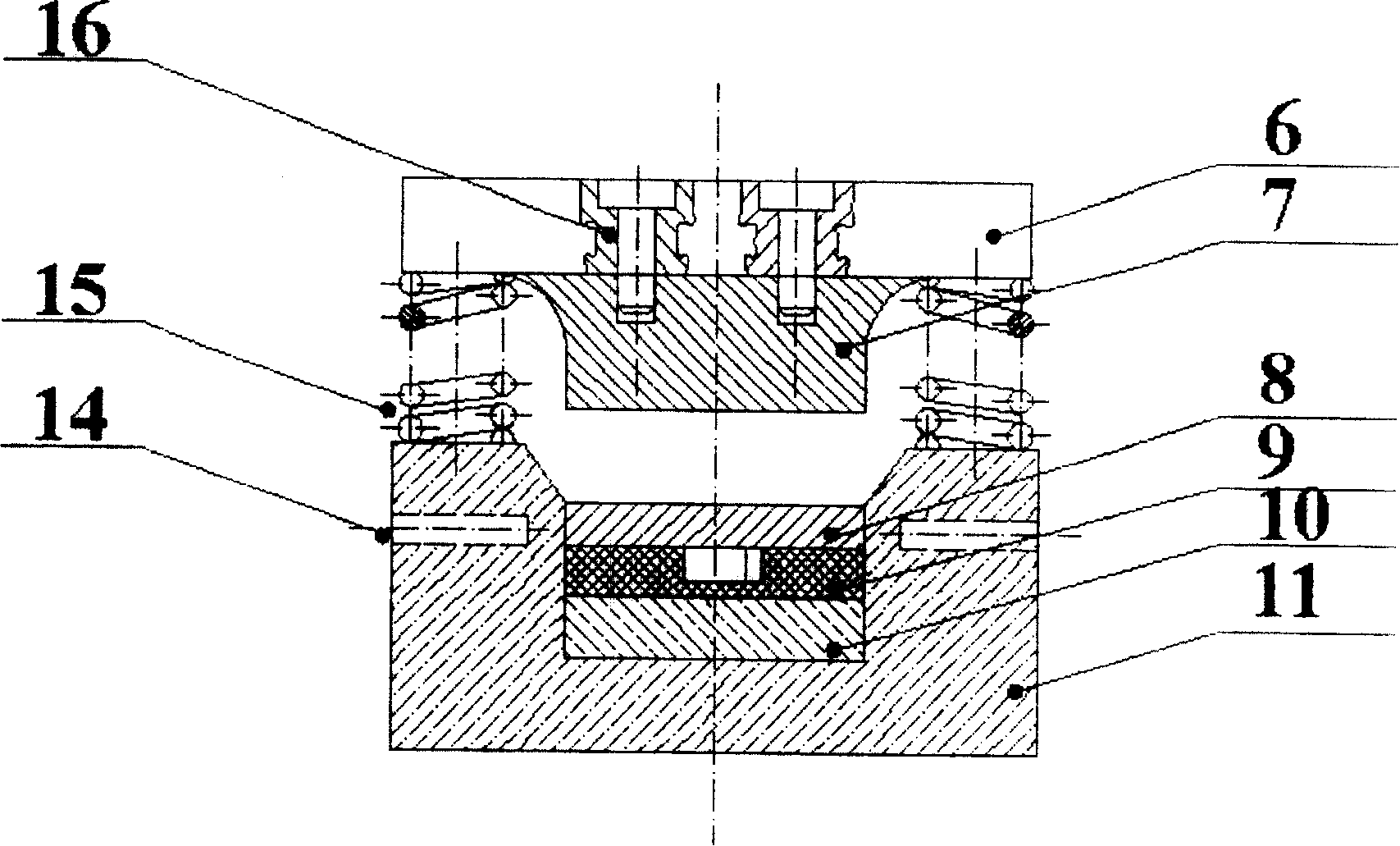

[0045] Combine below figure 2 with Figure 3-1 , 3-2 This embodiment will be specifically described.

[0046] The processing device of the present invention consists of a micro linear motor 1, an upper pressing head 2, a limit sleeve 3, a magnetostrictive actuator 4, a gas-protected non-contact heating furnace 5, a punch base 6, a punch 7, a blank 8, Die 9, cushion block 10, mold base 11, positioning pin 12, lower pressure head 13, temperature measuring blind hole 14, return spring 15 and connecting screw 16, wherein: miniature linear motor 1 is connected with the top of upper pressure head 2, Used to apply a larger output displacement. The neck of the upper pressure head 2 is provided with a limit sleeve 3 to avoid damage to the magnetostrictive actuator 4 due to an excessive stroke. The lower end of the upper pressing head 2 is installed in the gas shielded non-contact heating furnace 5 . The non-contact heating furnace 5 uses a fan to evenly transmit the heat generate...

Embodiment 2

[0056] Combine below figure 2 and Fig. 4-1, 4-2 specifically illustrate this embodiment. The processing device differs from that of Embodiment 1 in that the mold 9 is a double-layer multi-tooth coded gear concave mold.

[0057] The processing technology includes the following steps:

[0058] 1. According to the specific outline size of the coding gear, choose a large piece of Mg with a diameter of 2mm and a thickness of 1.6mm 65 Cu 25 Y 10 Amorphous alloy billet 8 is used to prepare micro-extrusion dies for coded gears.

[0059] 2. Place the processing device equipped with the extrusion die as a whole in the non-contact heating furnace 5, and start heating after introducing 10MPa argon gas, and the heating temperature is between 180 and 200°C (this embodiment takes 180°C as an example) .

[0060] 3. After the temperature of the double-layer multi-tooth extrusion die 9 is stable, quickly put the bulk amorphous alloy billet 8 in, and continue heating until the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com