Single component surface decorative organic silicon sealing material and its preparation process and application

A sealing material and modification technology, which is applied in the field of one-component surface-modified silicone sealing materials, can solve the problem of high activity of amide crosslinking agent and primary amine group, which does not involve improving the coatability of latex paint, water-based latex Improve the poor effect of paint and other problems, achieve stable performance, improve storage stability, and excellent weather aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]100 parts of hydroxyl-terminated polydimethylsiloxane (25°C, 35,000cP), 100 parts of dry superfine activated calcium carbonate (produced by Hunan Jinxin Chemical Co., Ltd., particle size in 0.04-20μm) mixed in a mixer for 2-3 hours under vacuum airtight to obtain a uniform base rubber, then add 8 parts of methyl tributylketoximosilane and stir in vacuum for 8-15 minutes, then add 0.1 parts of dibutyl dibutyl Tin laurate, 2 parts of self-made modified silane coupling agent 6A or 7A, DL-602, KH-792, stirred for 5-10 minutes under vacuum airtight condition, after removing bubbles and some low molecular substances generated in the reaction, Keep airtight.

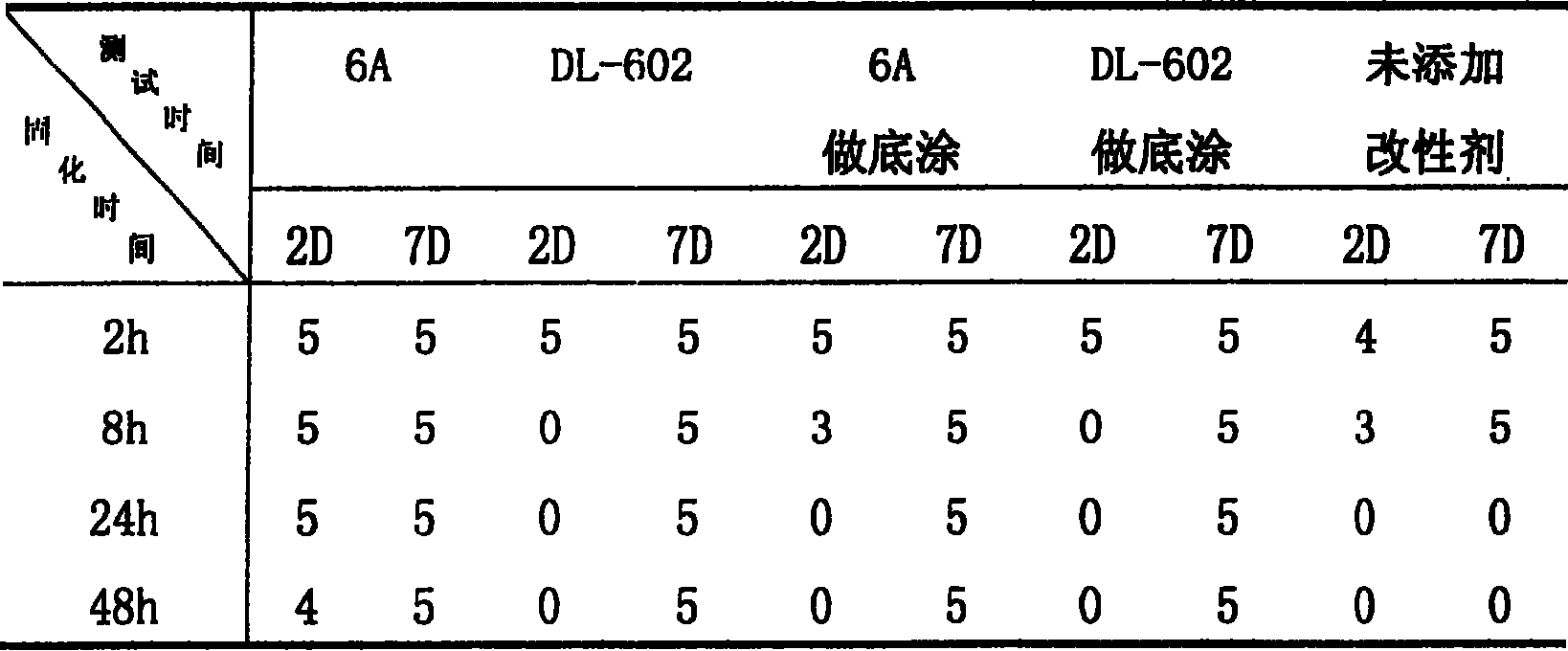

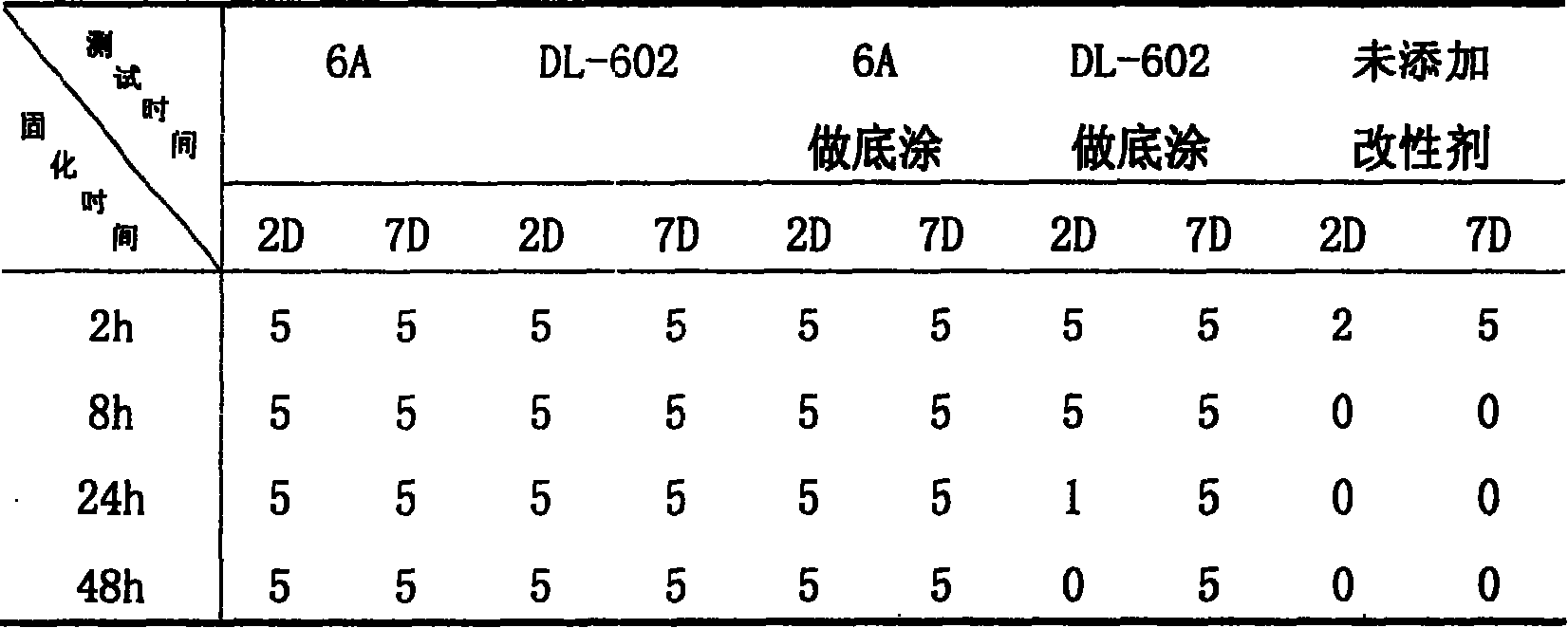

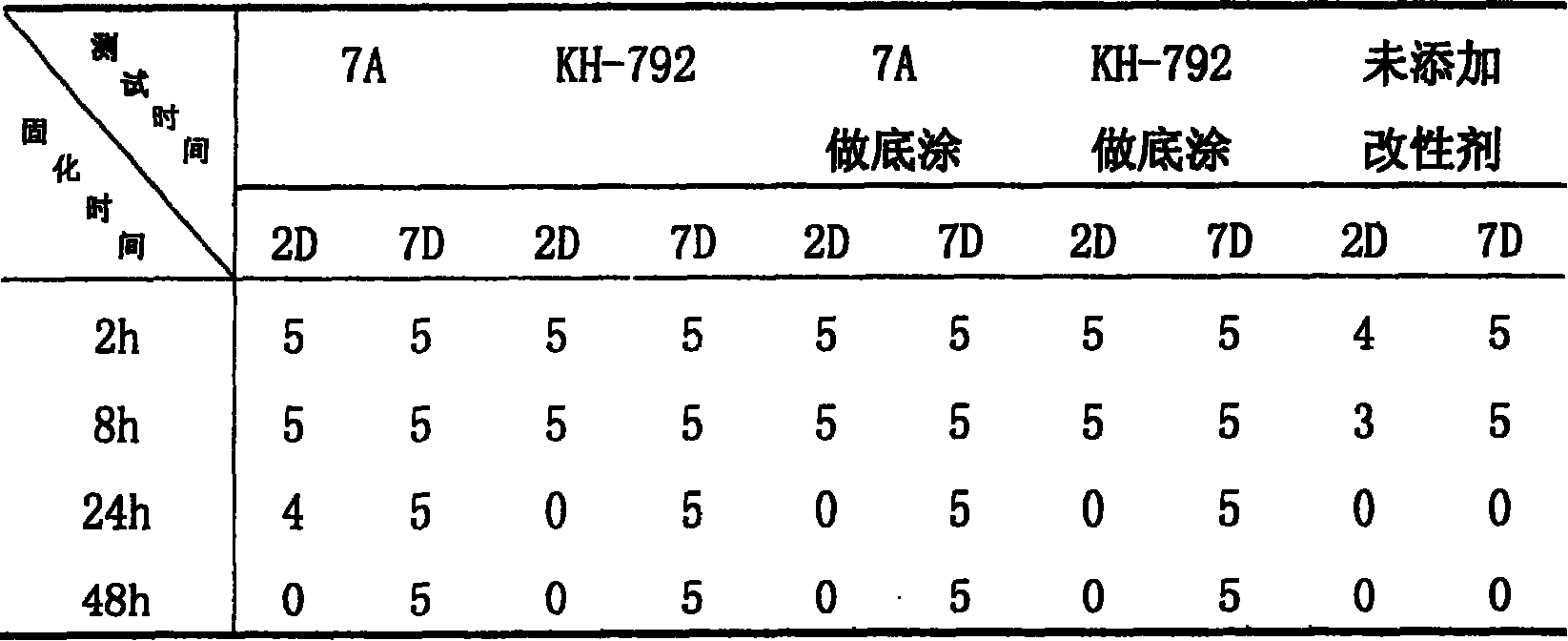

[0026] Apply the prepared silicone sealant evenly in a 2mm deep mold or a thin layer on the cured sealant without modifiers as a primer, and cure at room temperature for 2, 8, 24, 48 Hours later, evenly coat oil-based alkyd paint and polyurethane paint on it. After the coating was cured for 2 and 7 days, respectively, a...

Embodiment 2

[0061] Prepare the silicone sealant according to the method of Example 1, and add 1%, 2% and 3% of 6A respectively under the condition that other components remain unchanged, and test its surface coatability to the oil-soluble paint, as shown in Table 1 rating system to compare how well paint adheres to sealants. The test results are shown in Table 9 and Table 10.

[0062] The national standard GB / T 13477-92 was used for sample preparation and testing, and the silicone sealing material was made into an H-type sample, vulcanized and cross-linked for 28 days at 25°C and 50% RH, and its bonding strength to glass was tested. The group of samples is five samples, and the average test results are shown in Table 11.

[0063] Table 9 Effect of sealant on coatability of alkyd paint when adding different amounts of 6A

[0064]

[0065] Table 10 Effect of sealant on coatability of polyurethane paint when adding different amounts of 6A

[0066]

[0067] It can be seen from Table ...

Embodiment 3

[0072] Prepare the silicone sealant according to the method of Example 1. Under the condition that other components remain unchanged, add 3% methacryloylpropyltrimethoxysilane (trade name KH-570) to the system. Add 10-30% silicone acrylic latex to the acrylic latex paint to test its coatability on the surface of the water-soluble acrylic latex paint, and use the grade system in Table 1 to compare the degree of adhesion of the paint to the sealant.

[0073] Apply the prepared silicone sealant evenly on the mold with a depth of 2 mm and on the cured sealant without modifiers, and cure it at room temperature for 2, 8, 24, and 48 hours, and then apply it on it. Apply a mixture of water-soluble acrylic latex paint, silicone acrylic and oil-soluble acrylic enamel evenly. After the coating has cured for 2 days, 7 days, 18 days and 25 days respectively, determine the coatability of the coating to the surface of the sealant cured according to ASTM / D 3359-83 (Test method for pressure-se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com