Single component surface decorative organic silicon sealing material and its preparation process and application

A sealing material, silicone technology, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problem of high activity of amide crosslinking agent and primary amino group, not involved in improving the coatability of latex paint, and improving the water-based latex paint Insufficient effect and other problems, achieve stable performance, improve storage stability, and excellent weather aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]100 parts of hydroxyl-terminated polydimethylsiloxane (25°C, 35,000cP), 100 parts of dry ultrafine activated calcium carbonate (produced by Hunan Jinxin Chemical Co., Ltd., with particle size in 0.04-20μm) in a mixer and under vacuum sealing for 2-3 hours to obtain a uniform base compound, then add 8 parts of methyltributanone oximinosilane and stir in vacuum for 8-15 minutes, then add 0.1 part of dibutyldi Tin laurate, 2 parts of self-made modified silane coupling agent 6A or 7A, DL-602, KH-792, stirred for 5-10 minutes under vacuum sealed conditions, after removing air bubbles and some low molecular weight substances generated in the reaction, Store tightly sealed.

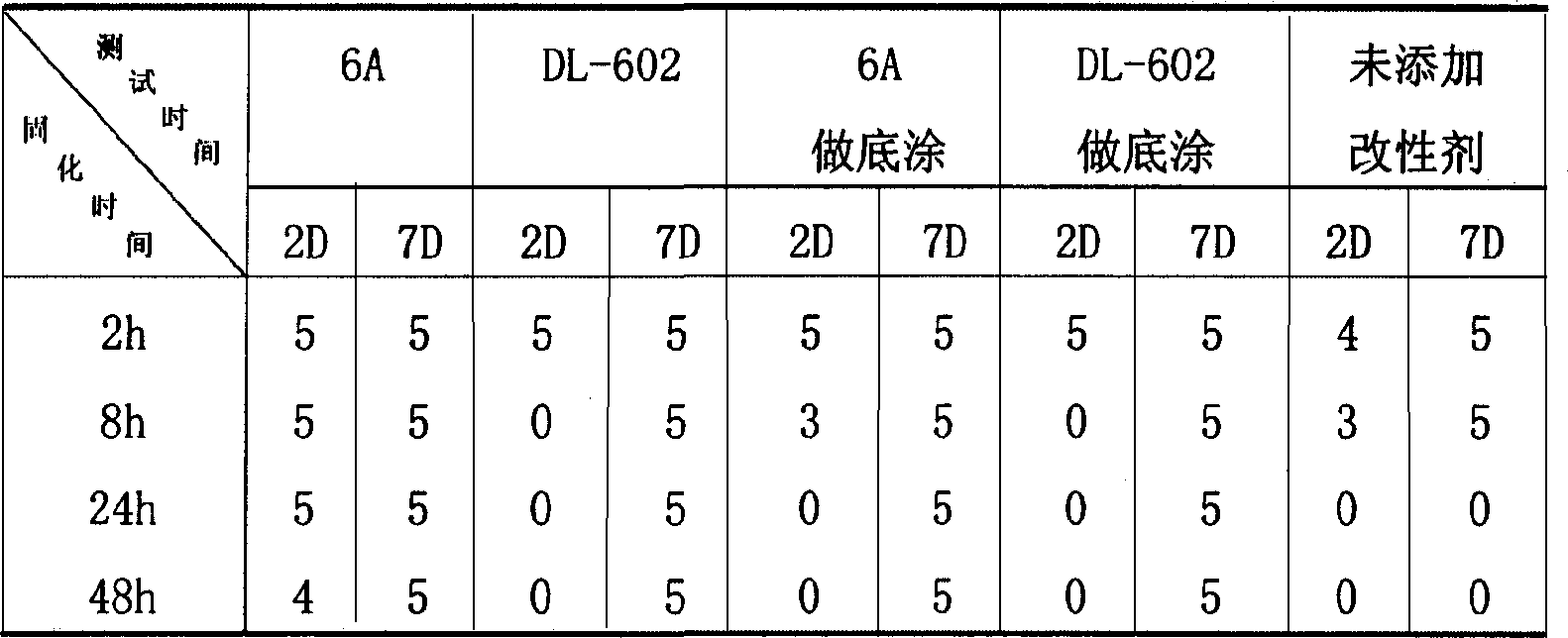

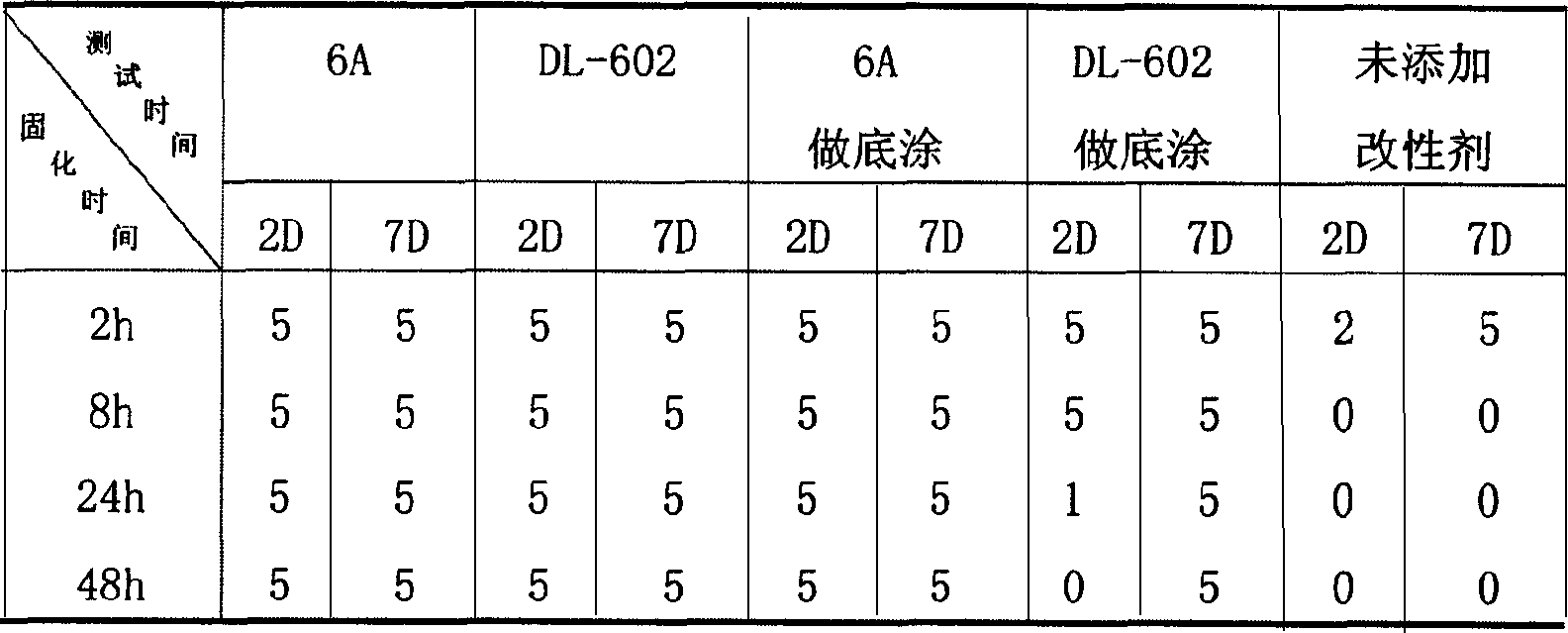

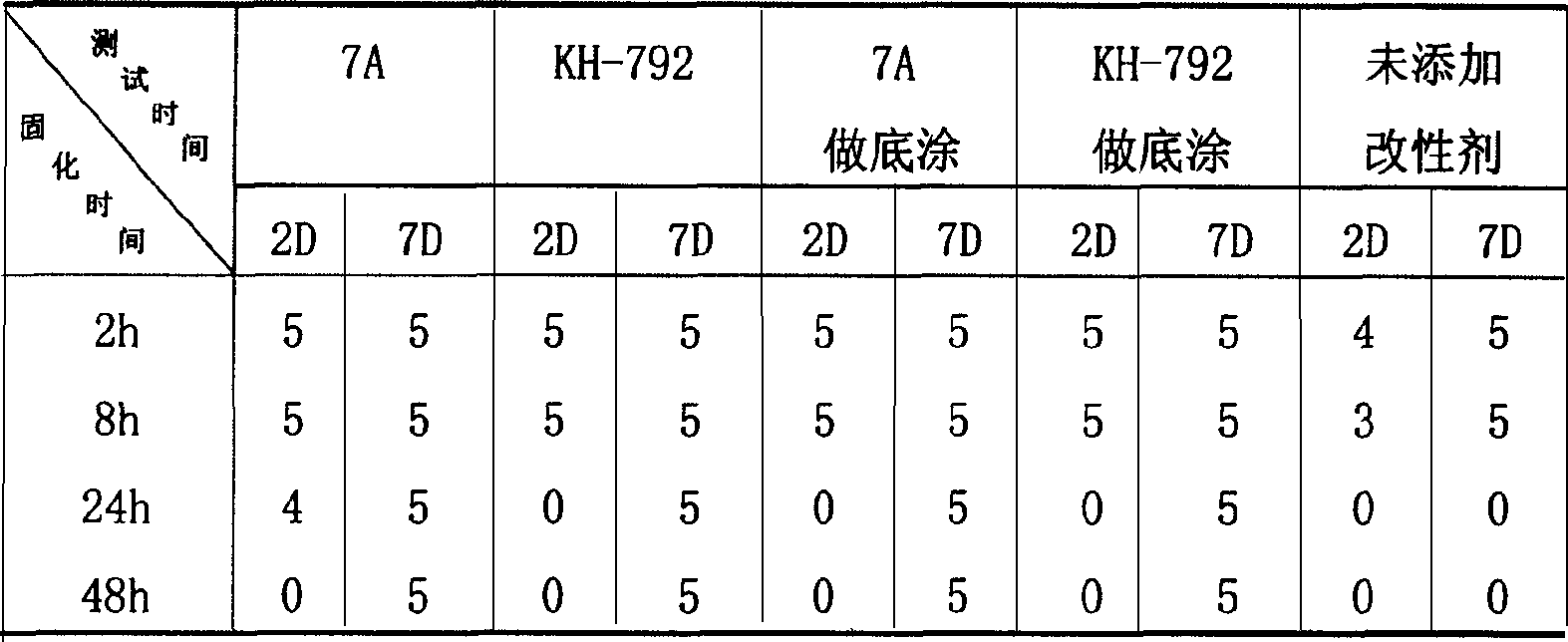

[0026] The prepared silicone sealant is evenly coated in a 2mm deep mold or a thin layer of the cured sealant without modifier added as a primer, and cured at room temperature for 2, 8, 24, 48 After an hour, apply oily alkyd paint and polyurethane paint evenly on it. After the coatings were cured for 2 a...

Embodiment 2

[0060] The silicone sealant was prepared according to the method of Example 1, and 1%, 2% and 3% of 6A were added respectively under the condition that other components remained unchanged, and the surface coatability of the oil-soluble paint was tested. Table 1 rating system to compare the adhesion of coatings to sealants. The test results are shown in Table 9 and Table 10.

[0061] Using the national standard GB / T13477-92 for sample preparation and testing, the silicone sealing material was made into H-type samples, vulcanized and cross-linked for 28 days under the conditions of 25 ° C and 50% RH, and the bonding strength to glass was tested. The sample is five samples, and the average test results are shown in Table 11.

[0062] Table 9 Influence of sealant on the coatability of alkyd paint when adding different amounts of 6A

[0063]

[0064] Table 10 The effect of sealant on the coatability of polyurethane paint when adding different amounts of 6A

[0065]

[0066...

Embodiment 3

[0071] The silicone sealant was prepared according to the method of Example 1. Under the condition that other components remain unchanged, 3% methacryloyl propyl trimethoxysilane (trade name KH-570) was added to the system. Add 10-30% silicone acrylic latex to the acrylic latex paint, test its coatability on the surface of water-soluble acrylic latex paint, and use the grade system in Table 1 to compare the adhesion of the paint to the sealant.

[0072] The prepared silicone sealant was evenly coated in a 2mm deep mold and on the cured sealant without modifier added, and cured at room temperature for 2, 8, 24, and 48 hours, respectively, and then applied on it. Apply a mixture of water-soluble acrylic latex paint, silicone acrylic and oil-soluble acrylic enamel evenly. After 2 days, 7 days, 18 days and 25 days of curing, the coatability of the coating to the cured surface of the sealant was determined according to ASTM / D3359-83 (Test Method for Pressure Sensitive Tapes), and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com