Autoclave synthesis method of sulfur group compound

A multi-metal and synthesis method technology, applied in the field of chalcogenide synthesis, can solve problems such as difficulty in ensuring stoichiometric ratio, difficult process parameters, and quartz ampoule bursting, so as to avoid the problem of quartz tube explosion, the process is simple, and the success is improved. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

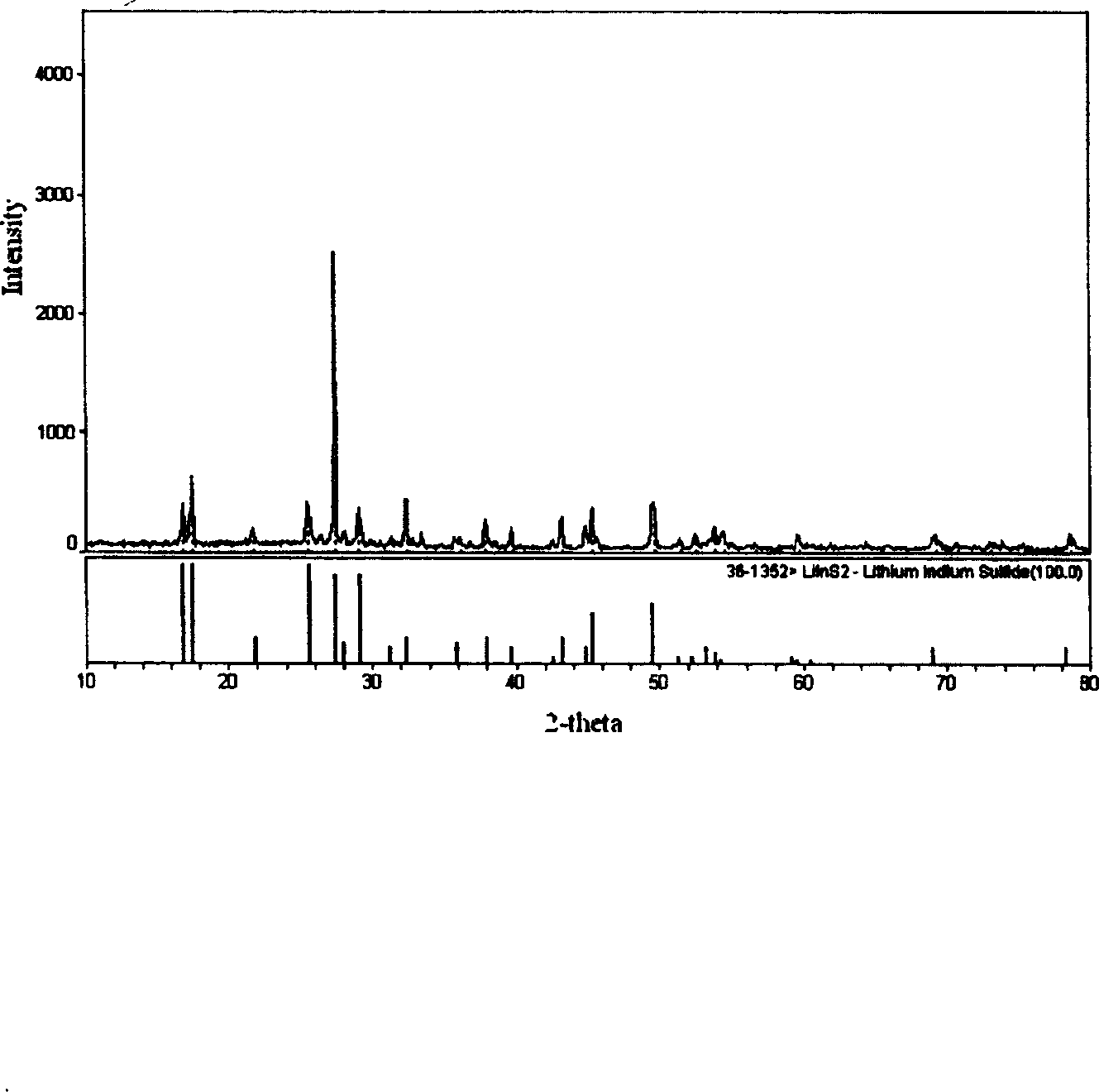

[0017] First, put the raw materials and graphite crucible into the oven to dry and remove water; in the glove box, accurately weigh the high-purity elemental raw materials Li(3N), In(4N) and S(4N) respectively according to the molar ratio of 1:1:2. ), taking into account the loss of S and Li, respectively, in excess of 10at% and 2at%. According to steps ③~⑥ in the process, the highest reaction temperature is controlled at 950°C, and LiInS can be obtained at constant temperature for 10 hours. 2 polycrystalline material. After grinding a small piece of polycrystalline material, do X-ray powder diffraction analysis, as shown in the attached figure, it proves that the obtained polycrystalline material is high-purity, single-phase LiInS 2 polycrystalline material.

Embodiment 2

[0019] First, put the raw materials and graphite crucible into an oven to dry and remove water; in the glove box, accurately weigh the high-purity elemental raw materials Li(3N), In(4N) and Se(4N) respectively according to the molar ratio of 1:1:2. ), taking into account the loss of Se and Li, respectively, in excess of 8at% and 4at%. According to steps ③~⑥ in the process, the maximum reaction temperature is controlled at 1000, and the temperature is kept at 20 hours to obtain LiInSe 2 polycrystalline material. After grinding a small piece of polycrystalline material, X-ray powder diffraction analysis proves that the obtained polycrystalline material is high-purity, single-phase LiInSe 2 polycrystalline material.

Embodiment 3

[0021] First, put the raw materials and graphite crucible into the oven to dry and remove water; in the glove box, accurately weigh the high-purity elemental raw materials Cu(4N), In(4N) and S(4N) respectively according to the molar ratio of 1:1:2. ), taking into account the volatilization loss of S, an excess of 2at%. According to steps ③~⑥ in the process, the highest reaction temperature is controlled at 1100 °C, and the temperature is kept at 25 hours to obtain CuInS 2 polycrystalline material. After grinding a small piece of polycrystalline material, X-ray powder diffraction analysis proves that the obtained polycrystalline material is high-purity, single-phase CuInS 2 polycrystalline material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com