Method for reducing temperature of high temperature slurry to vacuum filtering system feeding temperature in refined terephthalic acid production process

A technology for the production process of purified terephthalic acid, applied in chemical instruments and methods, carboxylate preparation, organic compound preparation, etc., can solve the problems of high energy consumption, large water consumption, large investment in equipment, etc., and achieve volumetric Small size, less cooling water consumption, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following structural drawings and embodiments further illustrate the present invention.

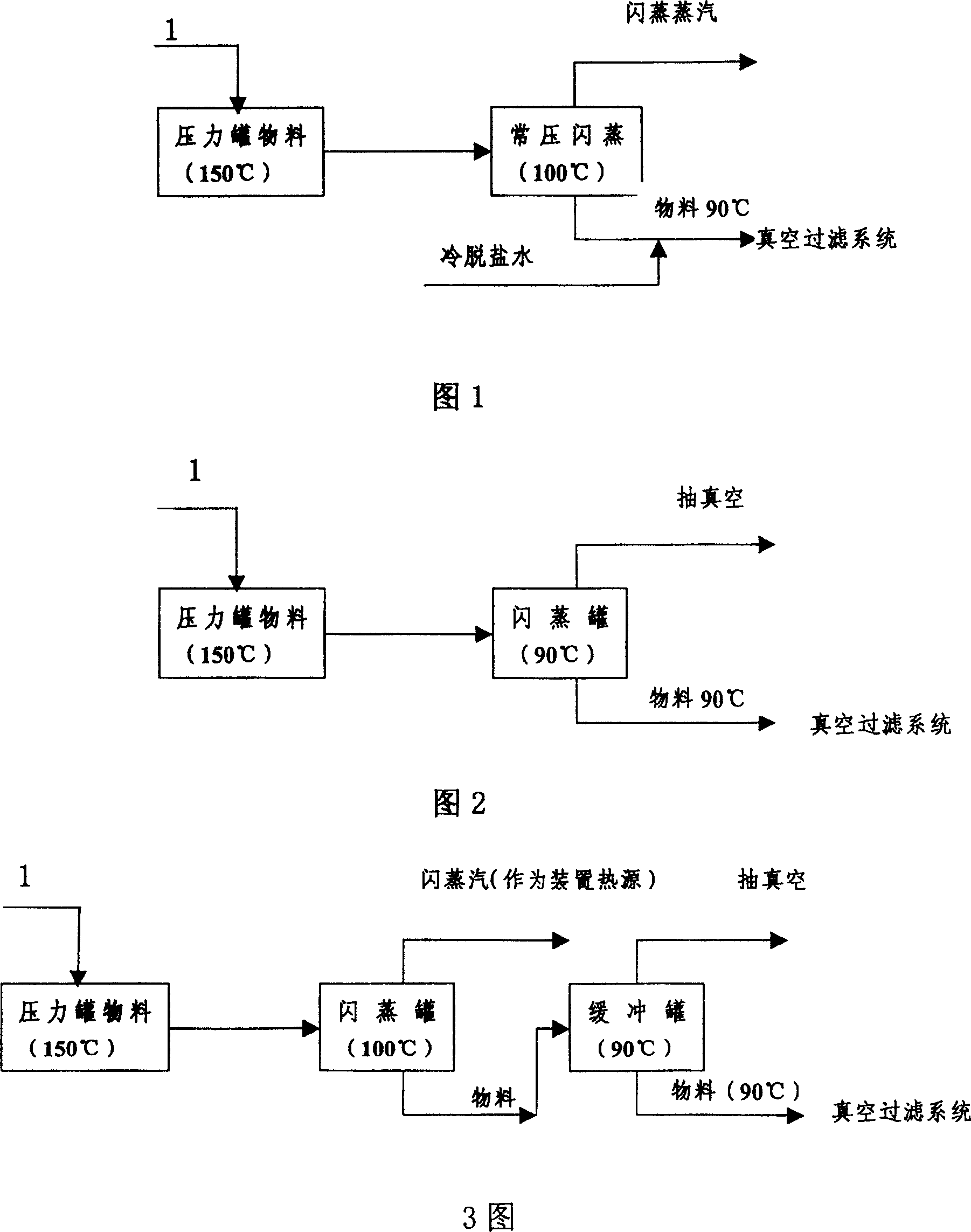

[0025] As shown in Figure 3.

[0026] A method for reducing high-temperature slurry to the feed temperature of a vacuum filtration system during the production of purified terephthalic acid, comprising the following steps:

[0027] a. First, the high-temperature slurry greater than 100°C produced in the previous process is centrifuged and then sent to an atmospheric flash tank for flash cooling, so that the temperature of the slurry is reduced to greater than 100°C and less than 115°C. Flash cooling slurry;

[0028] b. Next, send the above-mentioned flash cooling slurry into a buffer tank and use low-pressure steam injection to vacuumize and cool down, so that the temperature of the flash cooling slurry drops to the feed temperature of the vacuum filtration system.

[0029] The vacuum degree in the above-mentioned buffer tank is 30kPa~70kPa.

[0030] The waste heat generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com