Wet method combined process for desulfurization and denitration for chlorine-containing strong oxidizer absorption liquid

A strong oxidant, desulfurization and denitrification technology, applied in the field of wet combined desulfurization and denitrification technology, can solve the problems of inconvenient operation, difficult to achieve, complicated formula, etc., and achieve the effects of low cost, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

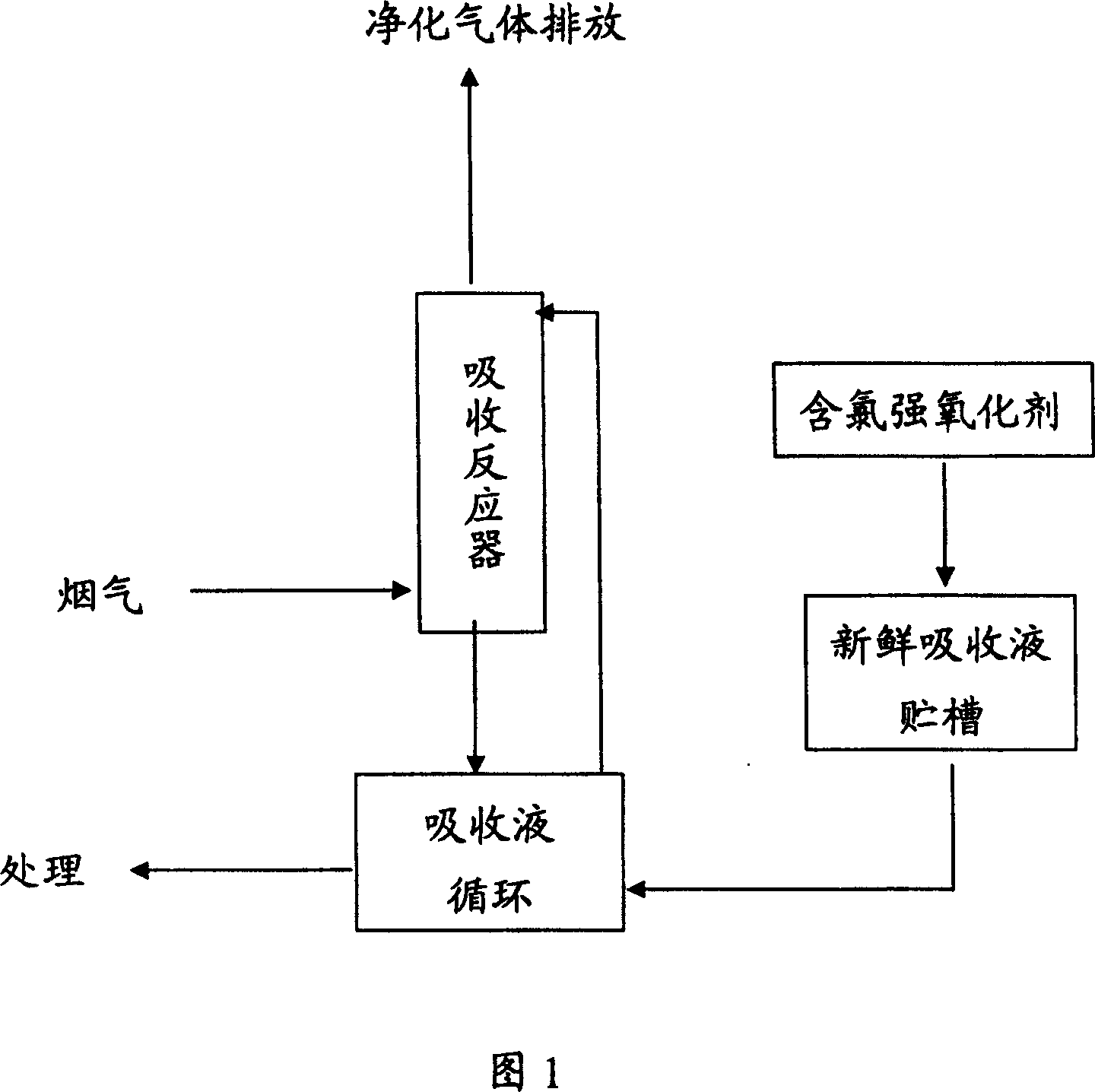

Image

Examples

Embodiment 1

[0019] Prepare 0.1% bleaching powder slurry as a highly active mixed absorption liquid for combined desulfurization and denitration, fully contact with the flue gas entering it in the bubbling reactor, and mix with NOx and SO in the flue gas 2 A chemical reaction occurs that removes the pollutants. The test results show that the nitrogen oxide removal efficiency of 60%-80% and the desulfurization efficiency of more than 90% can be achieved.

Embodiment 2

[0021] Prepare 5% bleaching powder slurry as a highly active mixed absorption liquid for combined desulfurization and denitrification, fully contact with the flue gas entering it in the bubbling reactor, and mix with NOx and SO in the flue gas 2 A chemical reaction occurs that removes the pollutants. The test results show that the nitrogen oxide removal efficiency of 70%-85% and the desulfurization efficiency of more than 95% can be achieved.

Embodiment 3

[0023] Prepare 15% bleaching powder slurry as a highly active mixed absorption liquid for combined desulfurization and denitrification, fully contact with the flue gas entering it in the bubble reactor, and mix with NOx and SO in the flue gas 2 A chemical reaction occurs that removes the pollutants. The test results show that the nitrogen oxide removal efficiency of 80%-95% and the desulfurization efficiency of more than 98% can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com