General hydraulic turbine for cooling tower

A technology for water turbines and cooling towers, which is used in hydropower generation, mechanical equipment, machines/engines, etc., can solve the problems that water turbines are not suitable for cooling towers, the noise is difficult to eliminate, and it is difficult to apply cooling towers, etc., to reduce vibration, extend service life, The effect of convenient maintenance and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

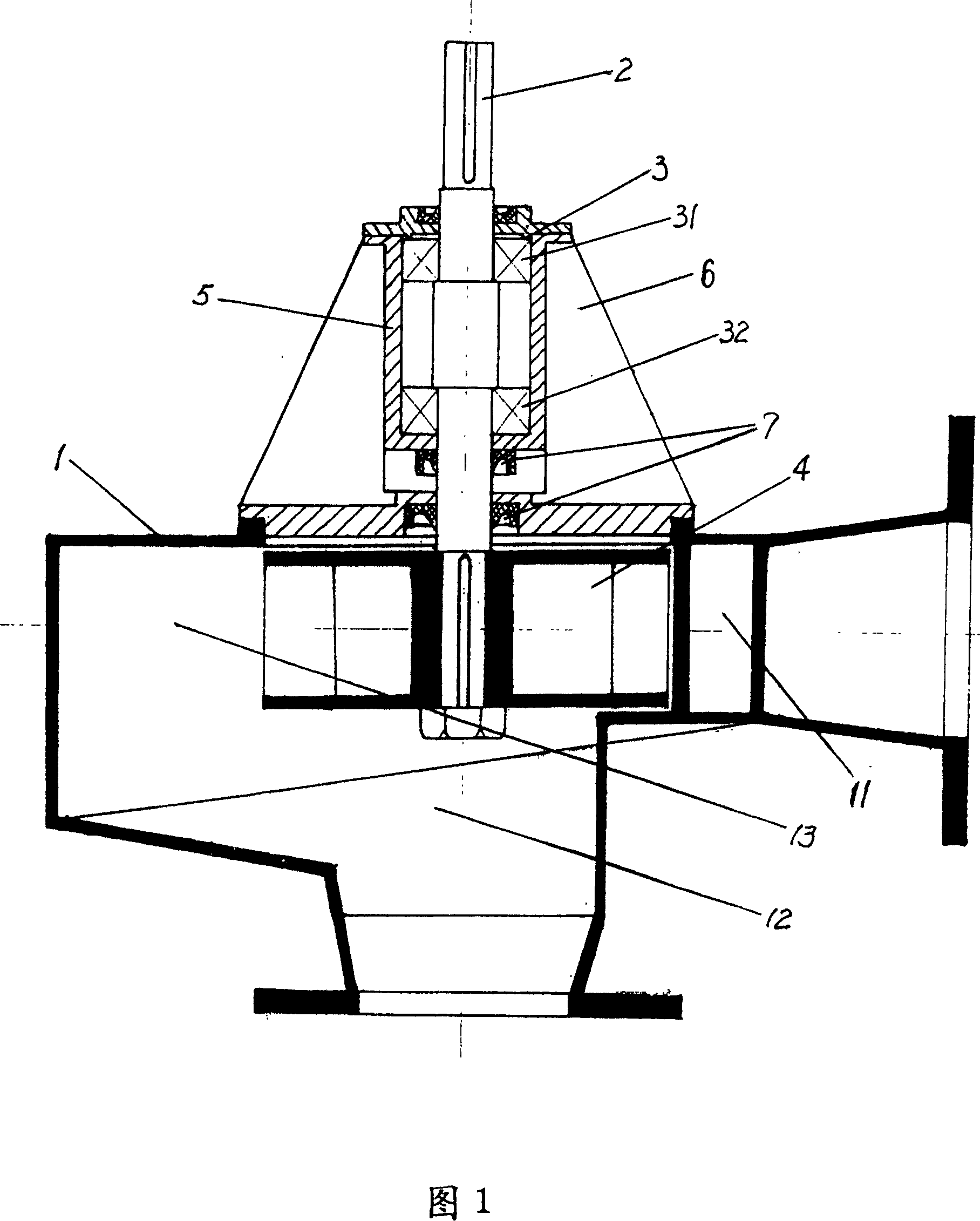

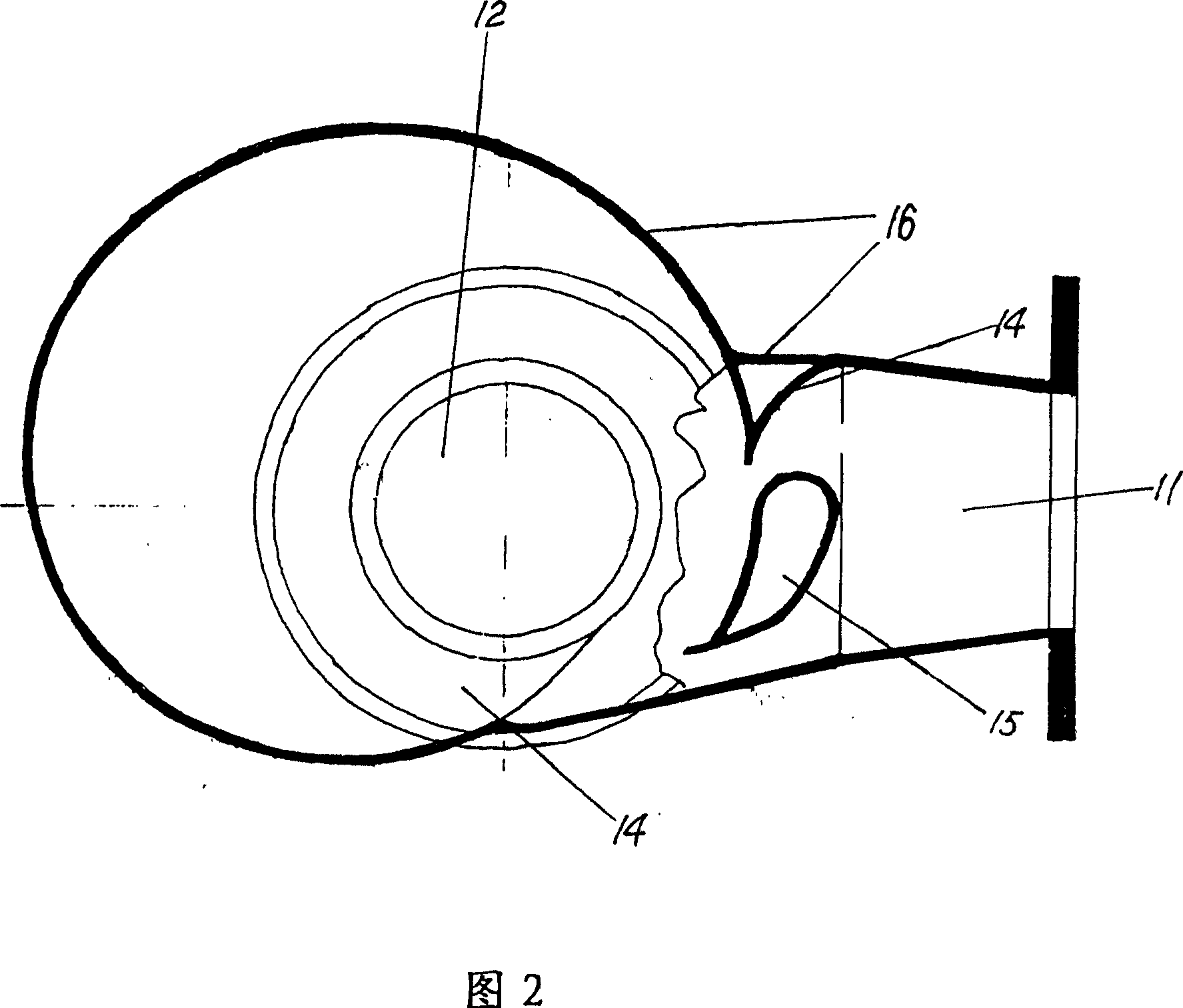

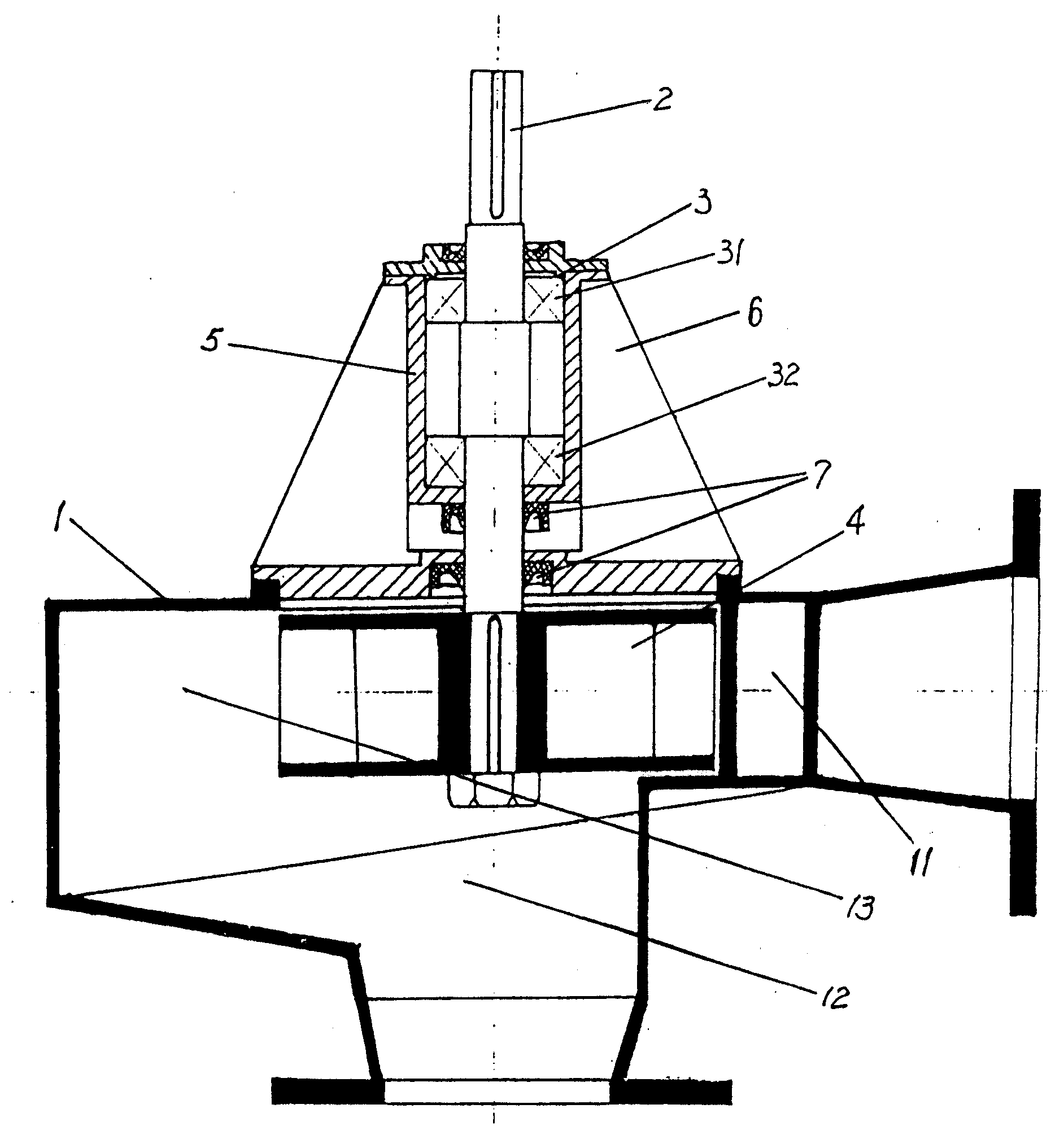

[0018] 1 and 2 , a general-purpose water turbine for a cooling tower of the present invention is equipped with a casing 1 , a main shaft 2 , a bearing 3 and an impeller 4 , and the impeller 4 is arranged on the main shaft 2 . The casing 1 is provided with a water inlet 11 and a water outlet 12 . The casing 1 is provided with a water outlet area 13, and the water outlet area 13 must satisfy the slow release space. The whole machine cancels the motor and reducer.

[0019] The bearing 3 is composed of an upper bearing 31 and a lower bearing 32, and is supported by a bearing seat 5, and the bearing seat 5 is connected with the bearing seat cover plate 6 into one body. A sealing ring 7 is installed at the connection with the main shaft 2 to prevent the leakage of circulating water.

[0020] The impeller 4 is arranged at the water inlet 11 . The number of blades of the impeller 4 is more than seven, and can reach nineteen or more. On the radial plane of the impeller 4, the gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com