Method for preparing 1,3-dimethyladamantane

A technology of dimethyladamantane and dibromoadamantane, applied in 1 field, can solve problems such as being unsuitable for industrial production, and achieve the effects of improving product purity and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

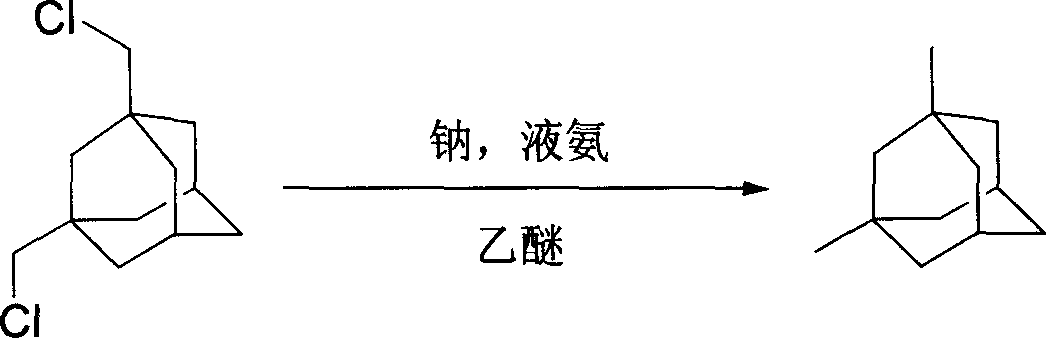

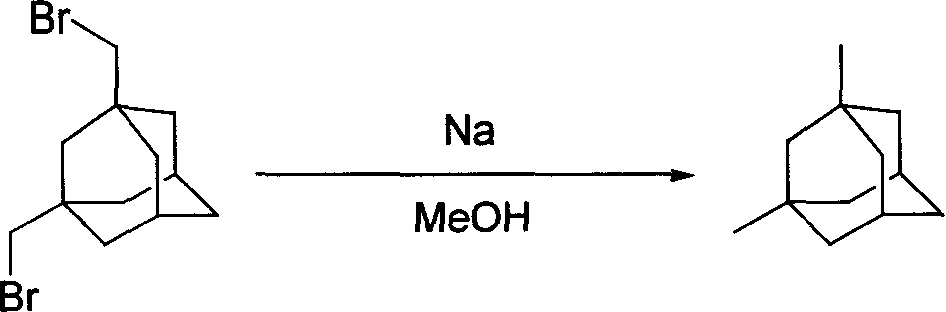

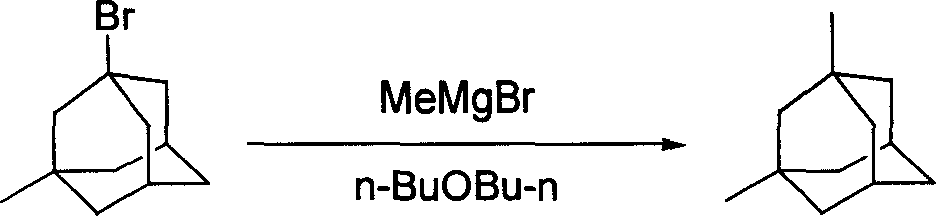

Method used

Image

Examples

Embodiment 1

[0028] Add 1.1 mL (1.72 g, 11 mmol) of titanium tetrachloride and 0.13 g (1 mmol) of titanium trichloride to 100 mL of dimethylzinc (1M) in dichloromethane under rapid stirring below 0 °C aluminum. After continuing to stir for 1 hour, the resulting solution was slowly warmed to 10°C. A solution of 7.67 g (25.6 mmol) of 1,3-dibromoadamantane in dichloromethane (30 ml) was then slowly added dropwise. After stirring at this temperature for 3 hours the solution was poured into 30 ml of ice water. After acidification with concentrated hydrochloric acid, the organic phase was washed with sodium bicarbonate solution and water, dried with calcium chloride, and the solvent was removed. The crude product was isolated by distillation to give 3.2 g (75%) (B.p. 90-92° / 15 mmHg).

Embodiment 2

[0030] Add 1.1 mL (1.72 g, 11 mmol) of titanium tetrachloride and 0.13 g (1 mmol) of titanium trichloride to 100 mL of dimethylzinc (1M) in dichloromethane under rapid stirring below 0 °C aluminum. After continuing to stir for 1 hour, the resulting solution was slowly warmed to 5°C. A solution of 7.67 g (25.6 mmol) of 1,3-dibromoadamantane in dichloromethane (15 ml) was then slowly added dropwise. After stirring at this temperature for 3 hours the solution was poured into 30 ml of ice water. After acidification with concentrated hydrochloric acid, the organic phase was washed with sodium bicarbonate solution and water, dried with calcium chloride, and the solvent was removed. The crude product was isolated by rectification to obtain 3.5 g (82%) (B.p.90-92°C / 15mmHg).

Embodiment 3

[0032] To 100 ml of dimethylzinc (1M) in dichloromethane, 1.1 ml (1.72 g, 11 mmol) of titanium tetrachloride and 0.26 g (2 mmol) of trichloride were added below 0°C with rapid stirring. aluminum. After continuing to stir for 1 hour, the resulting solution was slowly warmed to 10°C. A solution of 7.67 g (25.6 mmol) of 1,3-dibromoadamantane in dichloromethane (15 ml) was then slowly added dropwise. After stirring at this temperature for 3 hours the solution was poured into 30 ml of ice water. After acidification with concentrated hydrochloric acid, the organic phase was washed with sodium bicarbonate solution and water, dried with calcium chloride, and the solvent was removed. The crude product was isolated by rectification to obtain 3.4 g (80%) (B.p.90-92° / 15 mmHg).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com