Method for the isolation of trimethylolpropane and sodium formate from a reaction mixture

A technology for trimethylolpropane and reaction mixture, which is applied in the field of separating trimethylolpropane and sodium formate, can solve the problems of reduced product yield, loss of trimethylolpropane, etc., and achieves improved yield, reduced three-waste pollution, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

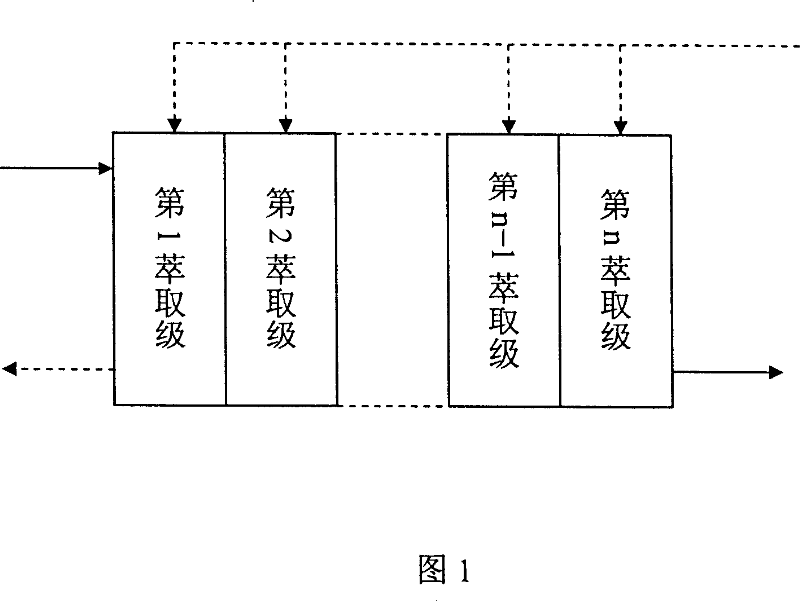

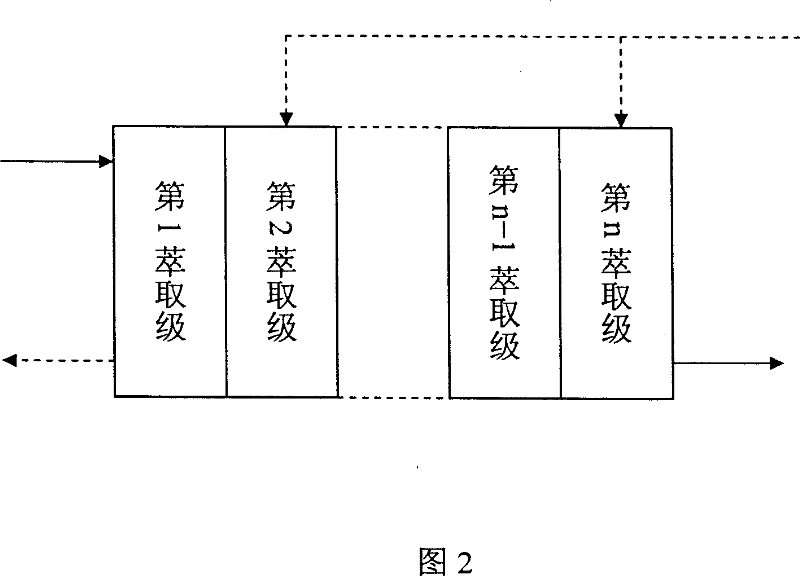

Method used

Image

Examples

Embodiment 1

[0031] Using a 5-stage combined extraction tank, the reaction mixture obtained in the above synthesis process is continuously fed into the combined extraction tank, the flow rate is 1800g / h, and the extraction agent n-butyraldehyde is continuously fed into each of the 5-stage tanks at the same time, and each stage is passed through The flow rate that enters n-butyraldehyde is all 250g / h, and the ratio of the total mass flow rate of organic solvent and the mass flow rate of reaction mixture is organic solvent: reaction mixture=0.69: 1 now. The extracted organic phase contained 33% (W / W) of trimethylolpropane, and the raffinate aqueous phase contained 14% (W / W) of sodium formate. The organic phase was rectified to obtain trimethylolpropane, and the aqueous raffinate was concentrated by evaporation to obtain sodium formate.

Embodiment 2

[0033] Using a 5-stage combined extraction tank, the reaction mixture obtained in the above synthesis process is continuously passed into the combined extraction tank, the flow rate is 1800g / h, and the extraction agent isobutanol is continuously fed into each stage of the 5-stage tank at the same time, and each stage is passed through The flow rate that enters isobutanol is all 500g / h, and the ratio of the total mass flow rate of organic solvent and the mass flow rate of reaction mixture is organic solvent: reaction mixture=1.39: 1 now. The extracted organic phase contained 17% (W / W) of trimethylolpropane, and the raffinate aqueous phase contained 14% (W / W) of sodium formate. The organic phase was rectified to obtain trimethylolpropane, and the aqueous raffinate was concentrated by evaporation to obtain sodium formate.

Embodiment 3

[0035] Using a 5-stage combined extraction tank, the reaction mixture obtained in the above synthesis process is continuously passed into the combined extraction tank, the flow rate is 1800g / h, and the extraction agent n-octanol is continuously fed into each stage of the 5-stage tank at the same time, and each stage is passed through The flow rate of entering n-octanol is 200g / h, and the ratio of the total mass flow rate of the organic solvent and the mass flow rate of the reaction mixture is organic solvent: reaction mixture=0.56:1. The extracted organic phase contained 41% (W / W) of trimethylolpropane, and the raffinate aqueous phase contained 14% (W / W) of sodium formate. The organic phase was rectified to obtain trimethylolpropane, and the aqueous raffinate was concentrated by evaporation to obtain sodium formate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com