Integral device for inoculating and culturing for edible mushroom liquid strain

A technology for liquid bacteria and edible fungi, which is applied in the cultivation devices of tissue cells/viruses, biochemical instruments, biochemical equipment and methods, etc., can solve the problems of low degree of automation, unsatisfactory process, inaccurate quantification, etc., and achieve automation The effect of high degree, easy to popularize and apply, and adjustable inoculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

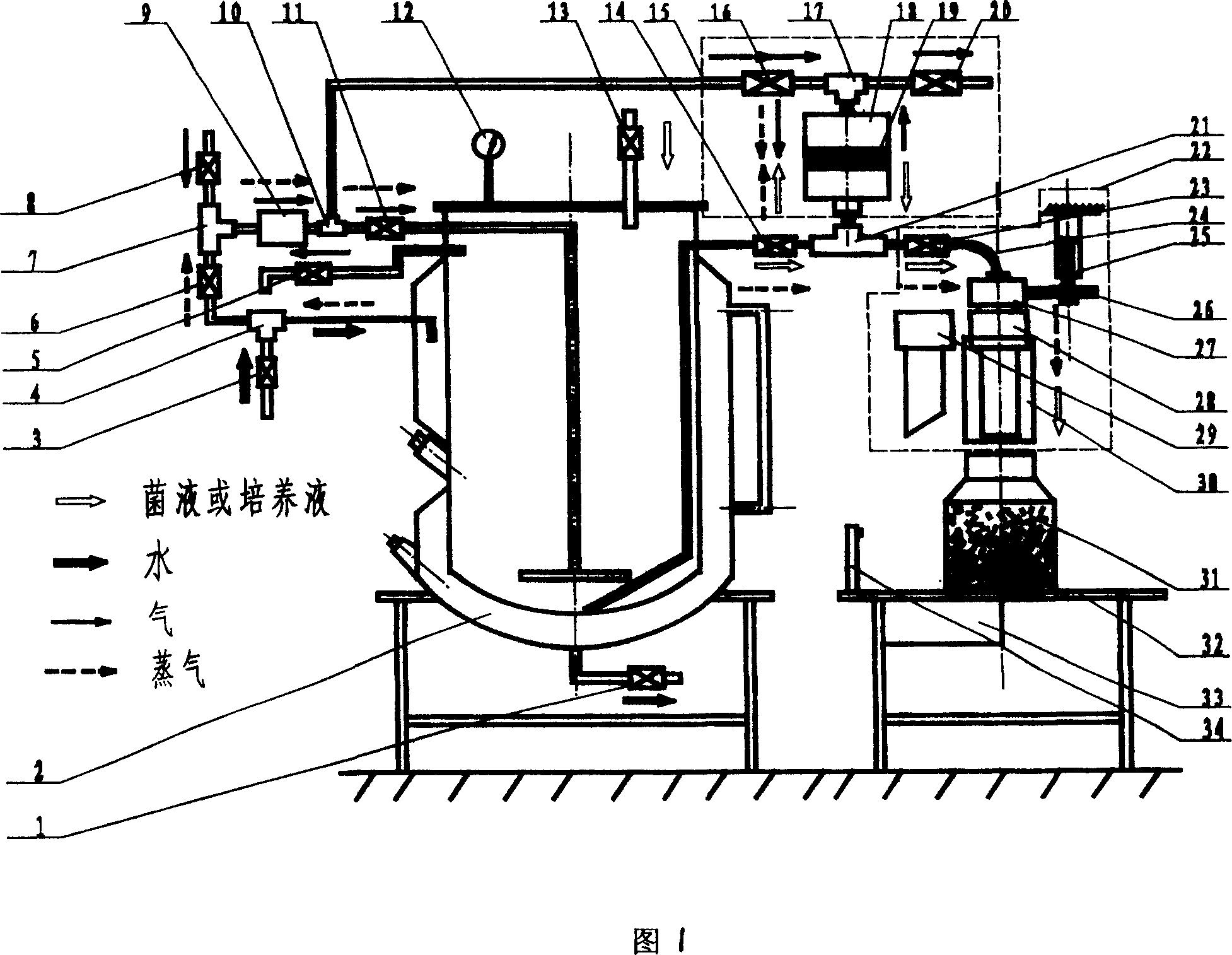

[0011] The integrated device for cultivation and inoculation of edible fungus liquid strains is shown in the figure. It is provided with a conventional culture tank body 2, on which a temperature detection and heating control device, a pH value detection device, a dissolved oxygen detection device, an air pressure detection device and a liquid level detection device are arranged. Also be provided with air intake pipe and solenoid valve 11, air outlet pipe and solenoid valve 5, bacteria liquid inlet pipe and electromagnetic hydraulic valve 13, bacteria liquid outlet pipe and electromagnetic hydraulic valve 14 on the cultivation tank body 2. The outlet pipe of the water heating layer of the cultivation tank 2 is connected with the valve 1, and the water inlet pipe is connected with the water inlet solenoid valve 3, the steam pipe and the solenoid valve 6 through the three-way joint 4 respectively. The steam pipe and the electromagnetic valve 6 are connected with the high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com