Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce gas loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing diesel oil with low condensation point by catalyst gradation technology

ActiveCN103805257ALow yieldGuaranteed yieldTreatment with hydrotreatment processesHydrogenation reactionSulfur

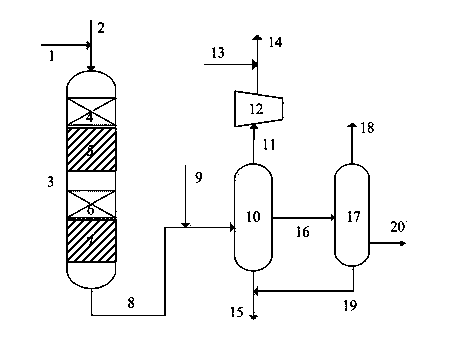

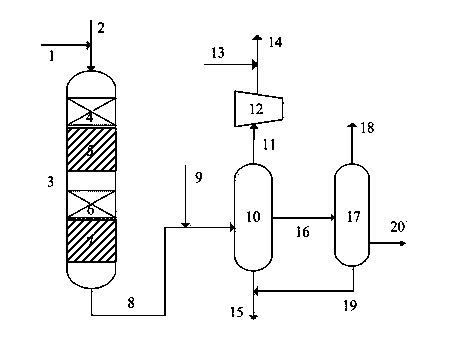

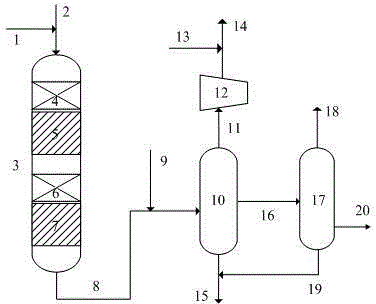

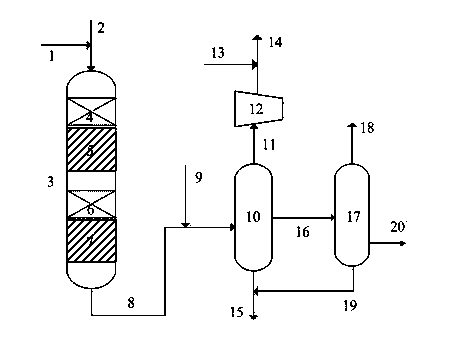

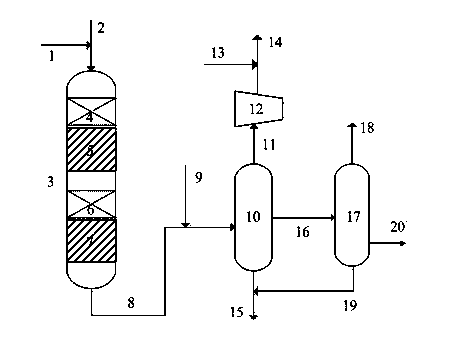

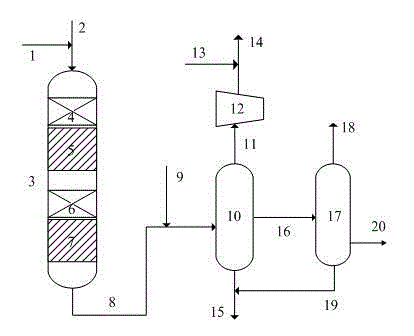

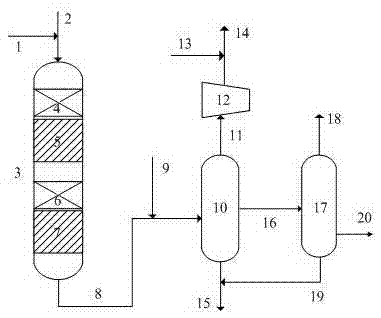

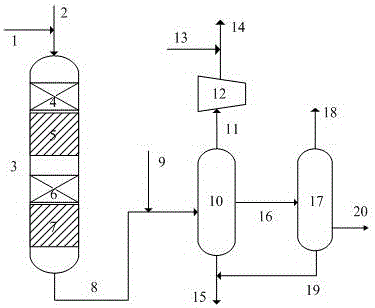

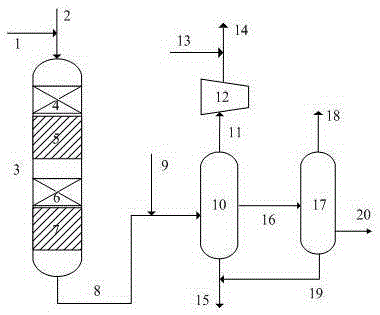

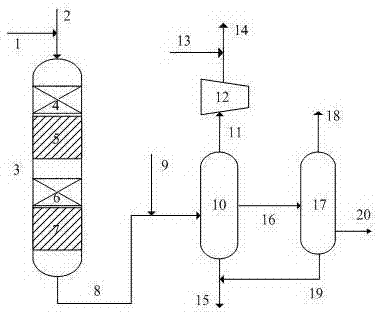

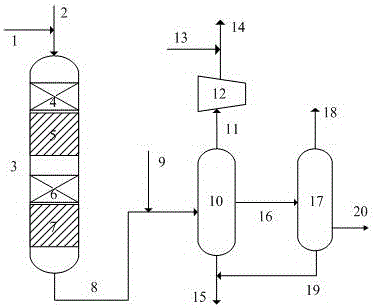

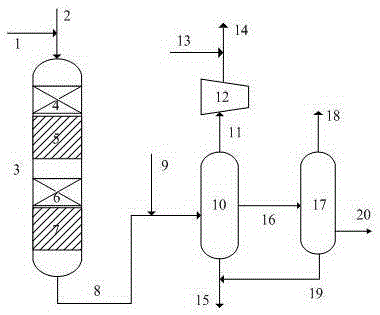

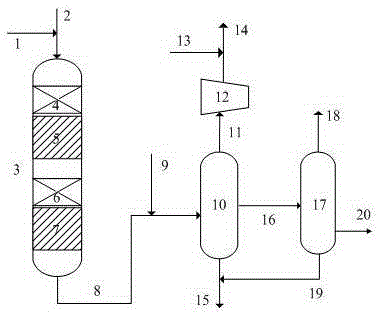

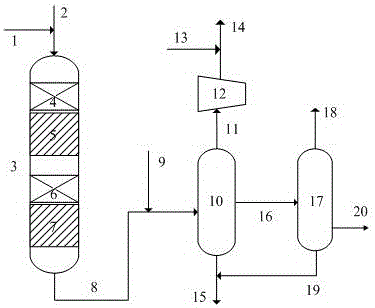

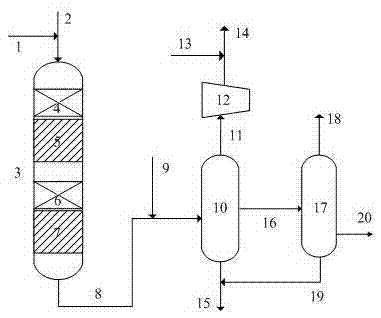

The invention discloses a method for producing diesel oil with a low condensation point by catalyst gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-refining dewaxing catalyst composite bed layer filled with a mixture of a hydro-refining catalyst and a hydro-upgrading isodewaxing catalyst, and a hydrodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing hydrogenated diesel oil with low condensation point by gradation technology

ActiveCN103805251ALow costRealize comprehensive utilizationTreatment with hydrotreatment processesHydrogenation reactionSulfur

The invention discloses a method for producing hydrogenated diesel oil with a low condensation point by gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-refining hydro-upgrading catalyst composite bed layer filled with a mixture of a hydro-refining catalyst and a hydro-upgrading catalyst, and a hydrodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature decrease of the hydrodewaxing process with the temperature increase of the hydro-upgrading process, improves the diesel oil yield while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

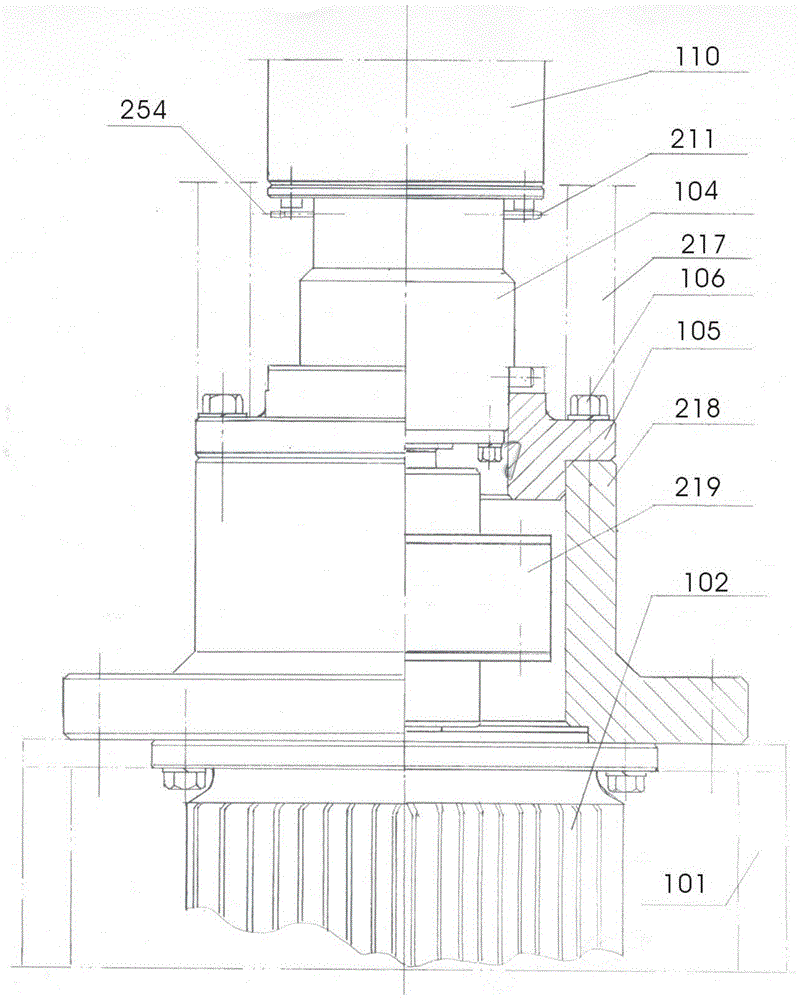

Shale gas content measurement device and method

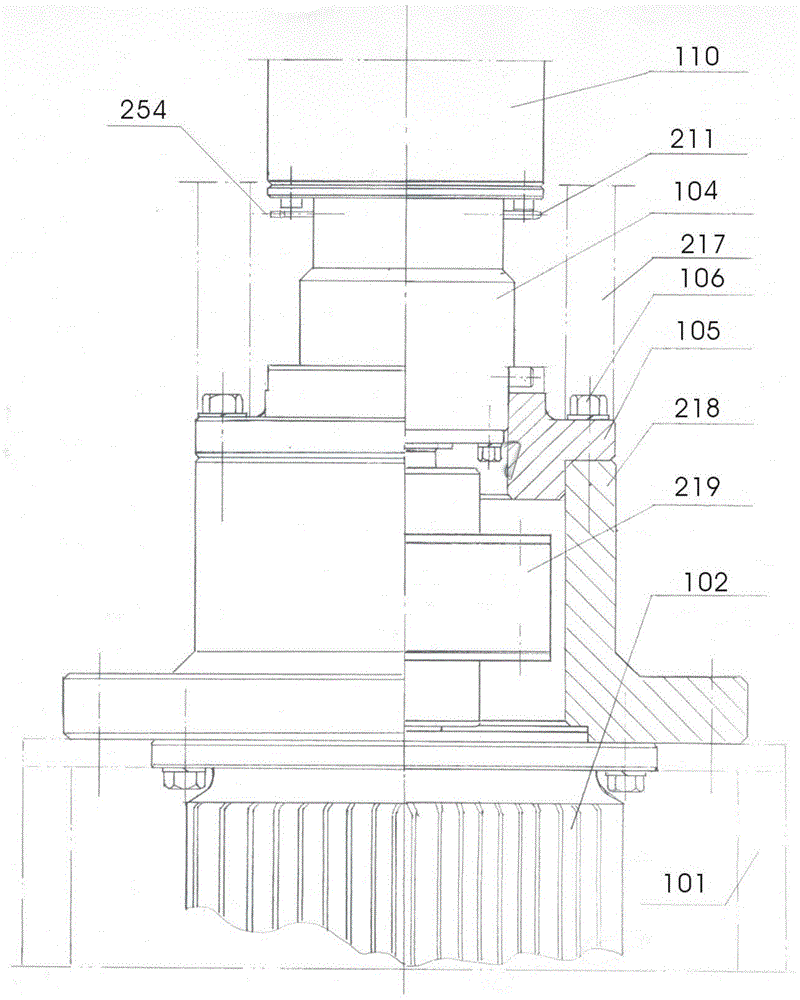

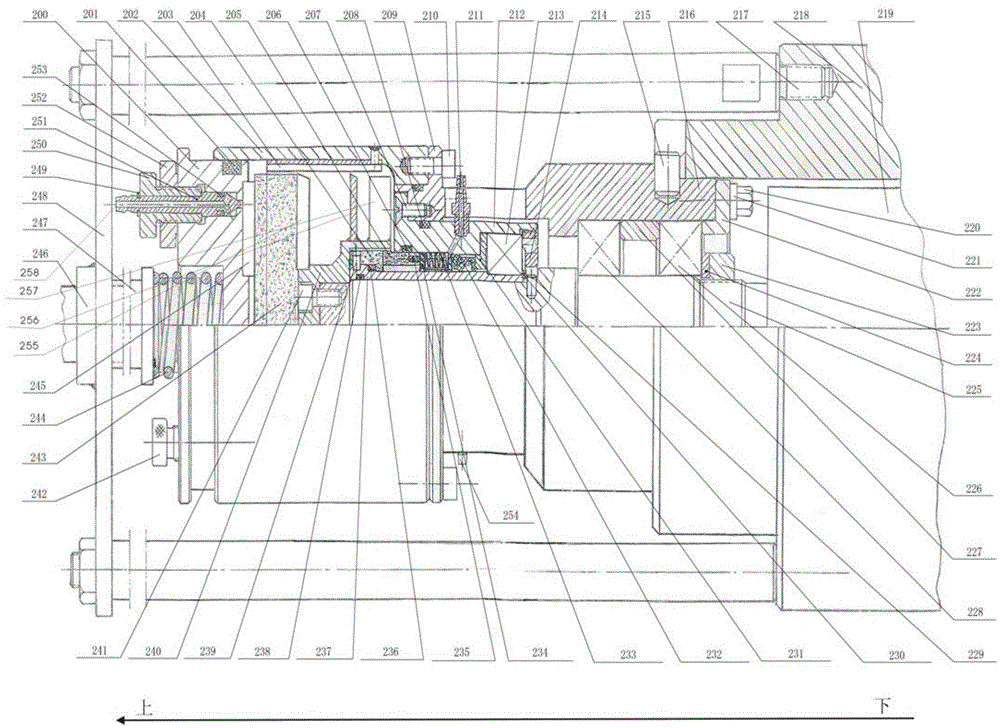

ActiveCN104678076AReduce gas lossThe test results are accurateEarth material testingShale gasMeasurement device

The invention discloses a shale gas content measurement device and a shale gas content measurement method. The measurement device comprises a fixed base, a driving mechanism, a sealed sample crushing cylinder, a crushing combined tool and a seal cover, wherein the driving mechanism is connected to the fixed base; a cylinder body of the seal sample crushing cylinder is connected with the fixed base and is internally provided with a stirring shaft connected with the driving mechanism; the stirring shaft rotates under the driving of the driving mechanism; the crushing combined tool is connected to the stirring shaft of the sealed sample crushing cylinder and is matched for sample rough crushing and fine crushing; the seal cover is arranged at the opening of the seal sample crushing cylinder above the crushing combined tool and is connected with the sealed sample crushing cylinder in a sealed mode. The testing device cam seal, crush and degas the whole rock core or rock sample in an exploration field or a laboratory, so that the sample gas content can be obtained rapidly and accurately.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing hydrogenated diesel oil with low freezing point

ActiveCN104611033AHigh yieldIncrease cetane numberTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation reactionHeating furnace

The invention discloses a method for producing hydrogenated diesel oil with a low freezing point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, allowing the obtained mixture to sequentially go through at least two serially connected hydrogenation reaction zones, wherein the hydrogenation reaction zones sequentially comprise a pour point reduction modified catalyst composite bed layer filled with a hydrodewaxing catalyst and a hydroupgrading catalyst and a hydrodewaxing catalyst bed layer along a material flow direction; and separating a reaction effluent obtained from the last hydrogenation reaction zone, and fractioning to obtain a diesel oil product with a low freezing point. The method reasonably combines the temperature decrease of the hydrodewaxing process and the temperature rise of the hydroupgrading process, so the diesel oil with a low freezing point is produced, the yield and the cetane value of the diesel oil are improved, the hot spot temperature of a device is reduced, and the running period is prolonged; and the consumption of cold hydrogen or the combustion gas loss of a heating furnace is reduced, so the operating cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing diesel oil with low condensation point by gradation technology

ActiveCN103805259AGuaranteed yieldRealize comprehensive utilizationTreatment with hydrotreatment processesFractionationChemistry

The invention discloses a method for producing diesel oil with a low condensation point by gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-upgrading isodewaxing catalyst bed layer, and a dewaxing catalyst composite bed layer filled with a mixture of a hydro-upgrading isodewaxing catalyst and a hydrodewaxing catalyst; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating oil base oil production method

ActiveCN104611044ALow aromatic contentReduce consumptionTreatment with hydrotreatment processesLubricant compositionFractionationWhite oil

The present invention discloses a lubricating oil base oil production method. According to the lubricating oil base oil production method of the present invention, a wax oil raw material and hydrogen gas are mixed and then sequentially pass through at least two hydrogenation reaction zones connected in series, wherein each hydrogenation reaction zone sequentially comprises a composite catalyst bed layer filled with a hydrodewaxing catalyst and a hydrocracking catalyst in a mixed manner and a hydrodewaxing catalyst bed layer according to the material flowing direction, and the reaction effluent obtained from the last hydrogenation reaction zone is subjected to separation and fractionation to obtain the lubricating oil base oil, the white oil and other products. With the method of the present invention, the temperature decrease during the hydrodewaxing process and the temperature increase during the hydrogenation process are subjected to reasonable combination utilization, such that the low freezing point lubricating oil base oil is produced while the viscosity index is increased, the hot spot temperature of the device is reduced, and the operation period is prolonged; and the cold hydrogen consumption or the heating furnace fuel gas loss is reduced, and the operating cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing hydrogenated diesel oil with low condensation point by catalyst gradation technology

ActiveCN103805255AReduce hot spot temperatureGuaranteed yieldTreatment with hydrotreatment processesHydrogenation reactionSulfur

The invention discloses a Method for producing hydrogenated diesel oil with a low condensation point by catalyst gradation technology. The method comprises the following steps: mixing diesel oil with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a dewaxing hydro-upgrading catalyst composite bed layer filled with a mixture of a hydro-upgrading isodewaxing catalyst and a hydro-upgrading catalyst, and a hydrodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of high-quality diesel oil with low condensation point

ActiveCN103805260AQuality assuranceGuaranteed yieldTreatment with hydrotreatment processesFractionationRaw material

The invention discloses a production method of high-quality diesel oil with a low condensation point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-upgrading isodewaxing catalyst bed layer, and a hydro-refining dewaxing catalyst composite bed layer filled with a mixture of a hydrodewaxing catalyst and a hydro-refining catalyst; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

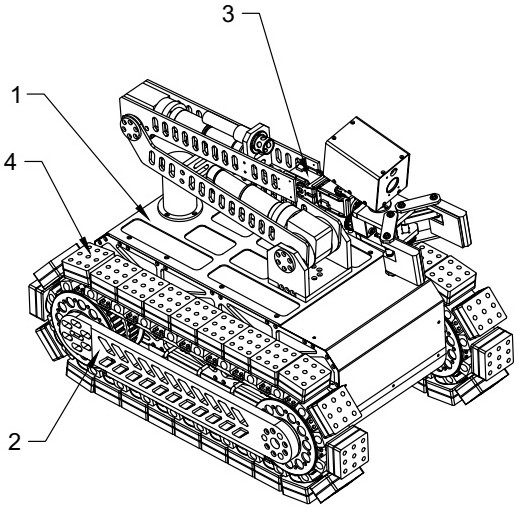

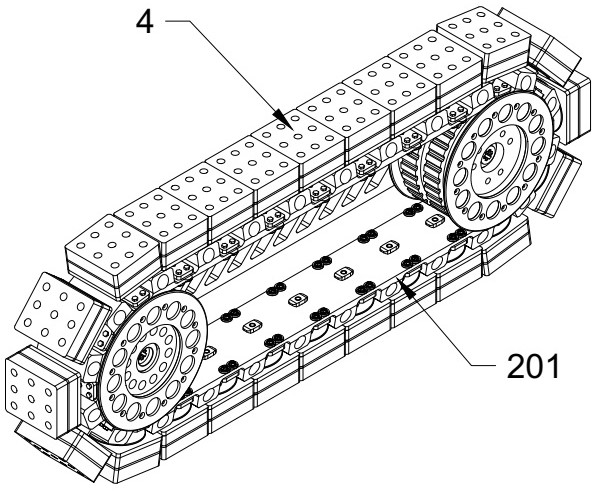

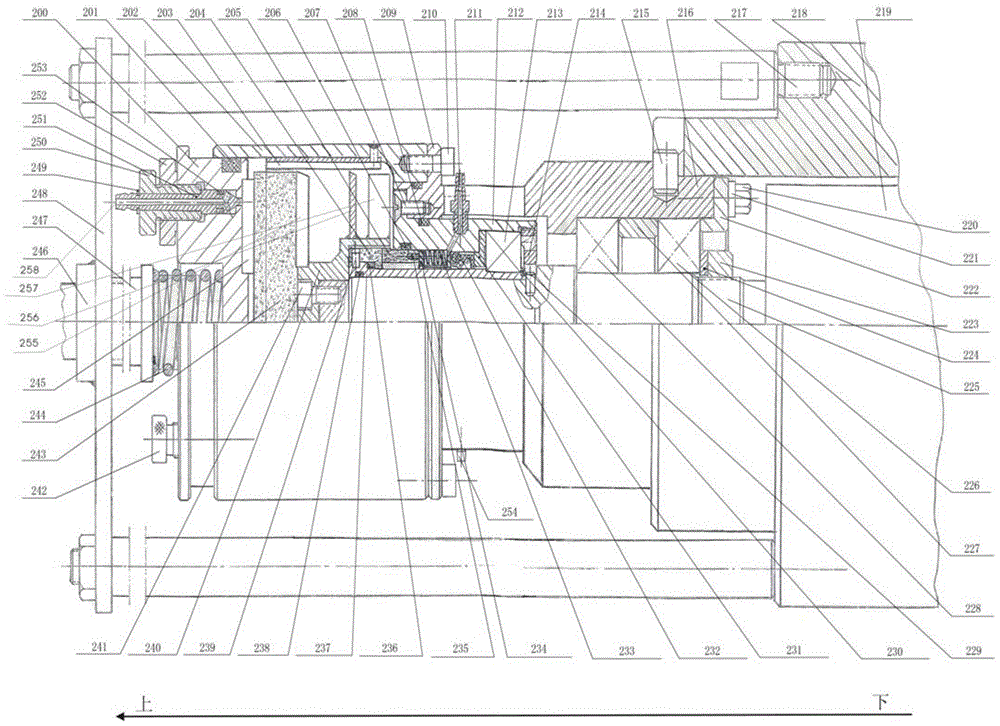

Self-adaptive wall-climbing robot for complex environment

ActiveCN112026949AIncrease elasticityStrong wrappingVehiclesControl engineeringStructural engineering

The invention discloses a self-adaptive wall-climbing robot for a complex environment. The robot comprises a robot body, porous self-adaptive suckers, an air distribution mechanism and a vacuum generation mechanism. The porous self-adaptive suckers are densely distributed on a crawler belt. Each porous self-adaptive sucker comprises a porous flexible adsorption plate, a bottom plate, a differential pressure one-way valve cavity, a rectangular boss, a vacuum adsorption pipe, a fixing plate, a sliding block, a large anti-skid nut, a fixing bolt and a small anti-skid nut. The air distribution mechanism comprises an air distribution groove, and the crawler belt is always fixed by negative pressure in the air distribution groove in the moving process and is tightly attached to the bottom of theair distribution groove. The porous self-adaptive suckers on the crawler belt move along with the crawler belt to dynamically seal the two ends of the air distribution groove, the vacuum generation mechanism is used for vacuumizing to generate negative pressure during adsorption, and an air distribution scheme that the porous self-adaptive suckers on the wall-climbing robot make full contact withan uneven surface and the suckers are distributed to a portion making contact with the ground at a fixed point can be achieved. And a gas loss of the vacuum generator can be effectively reduced.

Owner:CENT SOUTH UNIV

Method for producing high-quality diesel oil with low condensation point

ActiveCN103805263AImprove adaptabilityGuaranteed quality and yieldTreatment with hydrotreatment processesChemistryHeating furnace

The invention discloses a method for producing high-quality diesel oil with a low condensation point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-refining dewaxing composite catalyst bed layer filled with a mixture of a hydrodewaxing catalyst and a hydro-refining catalyst, and a hydro-upgrading isodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating oil base oil production method

ActiveCN104611035ALow aromatic contentReduce consumptionTreatment with hydrotreatment processesLubricant compositionFractionationOperating cost

The present invention provides a lubricating oil base oil production method. According to the method, a wax oil raw material and hydrogen gas are mixed and then sequentially pass through at least two hydrogenation reaction zones connected in series, wherein each hydrogenation reaction zone sequentially comprises a hydrodewaxing catalyst bed layer and a dewaxing cracking catalyst composite bed layer filled with a hydrodewaxing catalyst and a hydrocracking catalyst in a mixed manner according to the material flowing direction; and the reaction effluent obtained from the last hydrogenation reaction zone is subjected to separation and fractionation to obtain the lubricating oil base oil, the white oil and other products. With the method of the present invention, the temperature decrease during the hydrodewaxing process and the temperature increase during the hydrogenation process are subjected to reasonable combination utilization, such that the low freezing point lubricating oil base oil is produced while the viscosity index is increased, the hot spot temperature of the device is reduced, and the operation period is prolonged; and the cold hydrogen consumption or the heating furnace fuel gas loss is reduced, and the operating cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

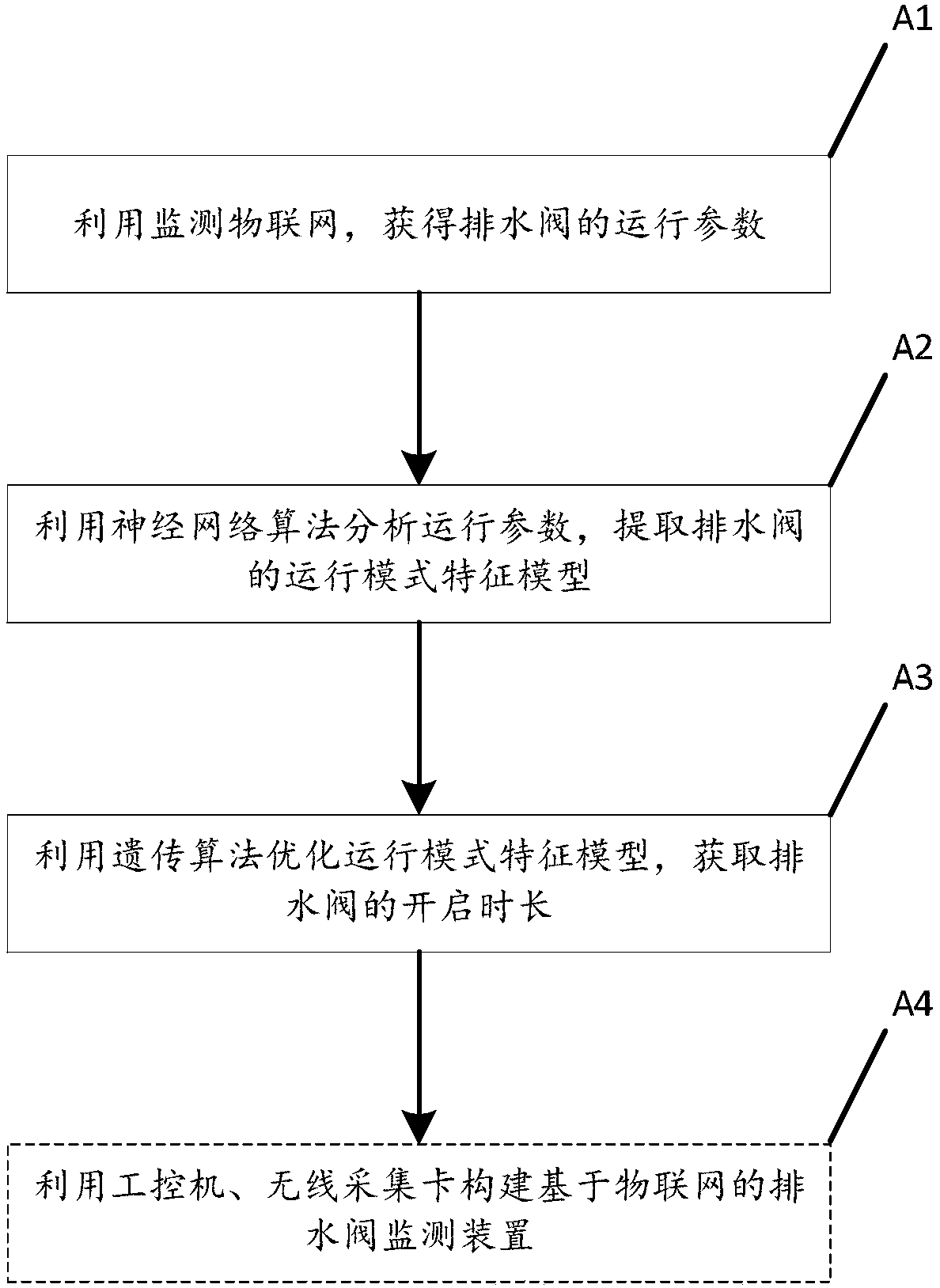

Internet-of-things-based drainage valve optimization method

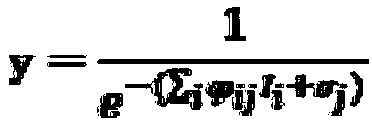

PendingCN108460476AOptimize opening timeReduce gas lossNetwork topologiesForecastingNerve networkAlgorithm

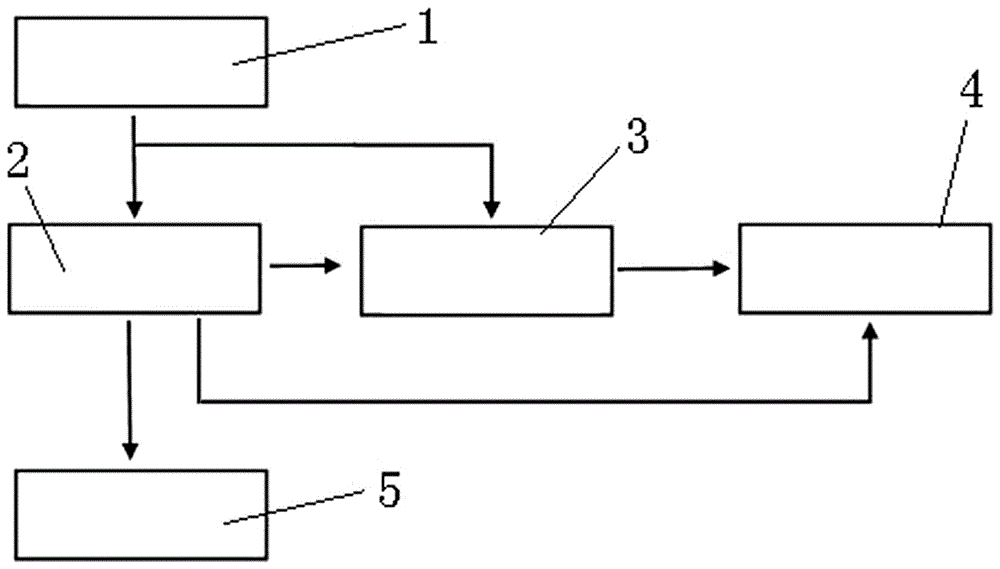

The invention provides an internet-of-things-based drainage valve optimization method. The internet-of-things-based drainage valve optimization method comprises: A1, acquiring operating parameters ofa drainage valve by monitoring an internet of things; A2, analyzing the operating parameters based on a neural network algorithm and extracting an operating mode feature model of the drainage valve; and A3, optimizing the operating mode feature model based on a genetic algorithm to obtain opening time of a valve. With the method provided by the invention, the gas consumption value is reduced.

Owner:浙江中睿低碳科技有限公司

Shale gas content testing device and testing method

The invention discloses a shale gas content measurement device and a shale gas content measurement method. The measurement device comprises a fixed base, a driving mechanism, a sealed sample crushing cylinder, a crushing combined tool and a seal cover, wherein the driving mechanism is connected to the fixed base; a cylinder body of the seal sample crushing cylinder is connected with the fixed base and is internally provided with a stirring shaft connected with the driving mechanism; the stirring shaft rotates under the driving of the driving mechanism; the crushing combined tool is connected to the stirring shaft of the sealed sample crushing cylinder and is matched for sample rough crushing and fine crushing; the seal cover is arranged at the opening of the seal sample crushing cylinder above the crushing combined tool and is connected with the sealed sample crushing cylinder in a sealed mode. The testing device cam seal, crush and degas the whole rock core or rock sample in an exploration field or a laboratory, so that the sample gas content can be obtained rapidly and accurately.

Owner:CHINA PETROLEUM & CHEM CORP +1

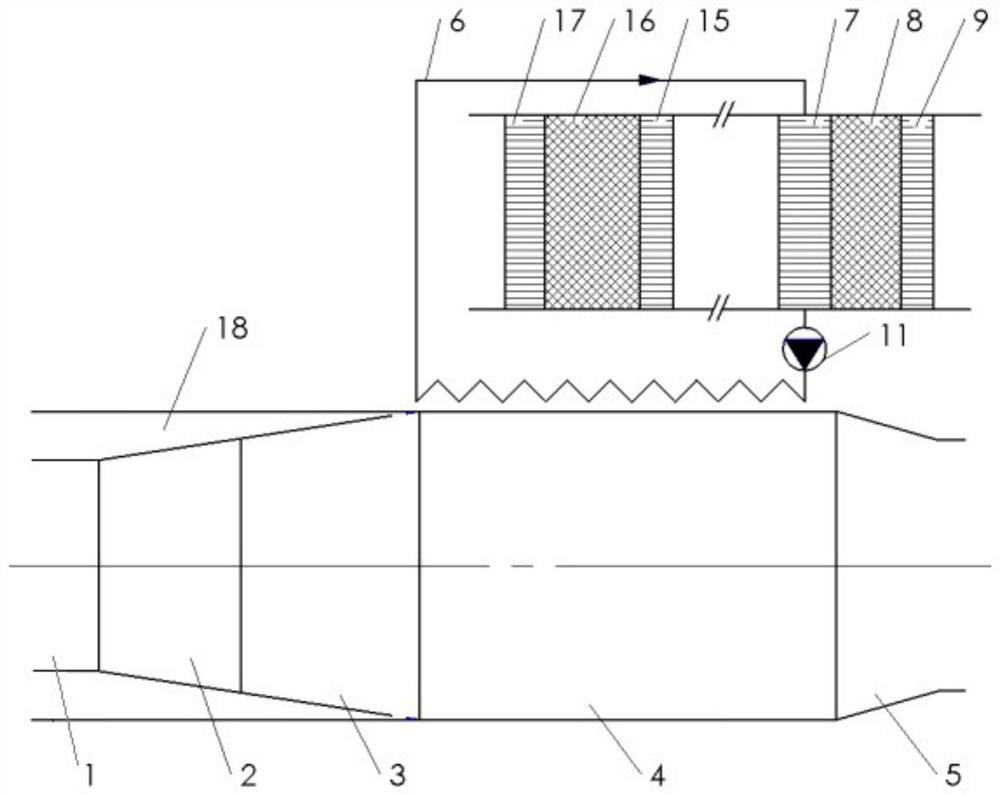

System of recycling wasteheat of aero-engine

InactiveCN111608807AImprove energy efficiencyReduce gas lossTurbine/propulsion engine coolingGas turbine plantsFlight vehicleProcess engineering

The invention relates to the technical field of engines, in particular to a system of recycling wasteheat of an aero-engine. The system of recycling the wasteheat of the aero-engine comprises the aero-engine, a thermo-acoustic engine and a heat carrying fluid pipeline. A part of the heat carrying fluid pipeline and a housing of the aero-engine are arranged in a fit manner, and the two ends of theheat carrying fluid pipeline are correspondingly connected to a heat carrying fluid inlet and a heat carrying fluid outlet of the thermo-acoustic engine. The system of recycling the wasteheat of the aero-engine provided by the invention can drive the thermo-acoustic engine to work by mean of heat transferred to the housing by air flow in the aero-engine so as to convert heat energy into mechanicalenergy, so that heat when the aero-engine works is recovered and the energy utilization ratio of the aero-engine is improved, and meanwhile, the gas quantity loss for cooling the housing of the aero-engine is reduced, the cooling problem of the aero-engine is solved effectively, the integral performance of the aero-engine is improved, and the system meets different demands of an aircraft.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

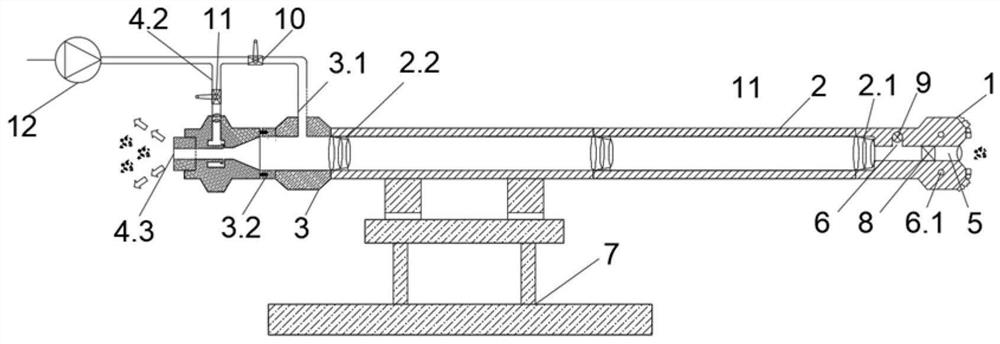

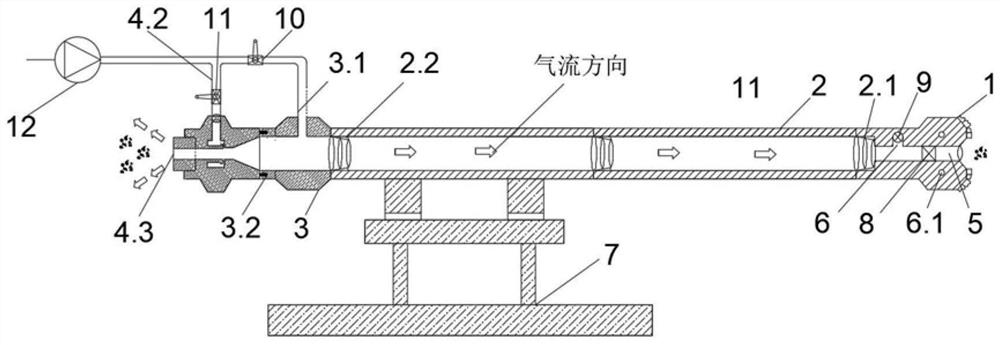

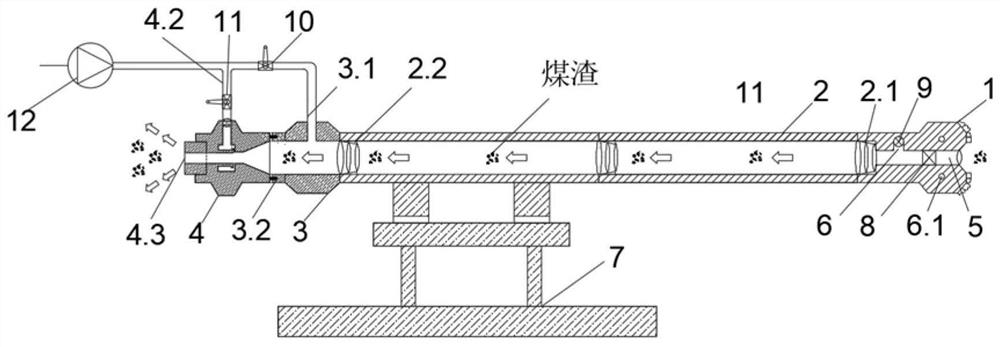

Low negative pressure injection deep hole continuous sampling system and sampling method

ActiveCN114592905AGuaranteed to passReduce negative pressure desorptionDrill bitsDrilling rodsGas analysisSlag

According to the low-negative-pressure injection deep hole continuous sampling system and method, a sampling hole is formed in a sampling drill bit and communicated with a hollow rod of a drill rod, an exhaust hole is formed in the rear side wall of a cavity in the sampling drill bit, and exhaust inclined holes are evenly distributed in the outer wall of the sampling drill bit and communicated with the exhaust hole; the matched water braid is of a hollow structure, an air-water pipeline is arranged on the side wall of the matched water braid, and the tail of the matched water braid is connected with the air amplifier. The air amplifier is of a hollow structure and is communicated with the matched water braid through an air inlet, a compressed air inlet nozzle is arranged on the side wall of the air amplifier, the air inlet end of the compressed air inlet nozzle is communicated with the air supply pipeline, and the air outlet end is communicated with the air amplifier; the tail end of the air amplifier is an exhaust and slag discharge port; on the premise of not withdrawing the drill and replacing the drill rod, sampling is continuously carried out at multiple sampling points, and it is guaranteed that coal samples at all the sampling points are not mixed; sampling can be conducted according to the sampling amount requirement, the influence of strong negative pressure airflow disturbance on coal sample gas analysis in the sampling process is reduced, and accurate coal seam sampling is achieved.

Owner:CHINA UNIV OF MINING & TECH

A kind of production method of low condensation diesel oil

ActiveCN103805270BGuaranteed yieldRealize comprehensive utilizationTreatment with hydrotreatment processesIsomerizationHydrogenation reaction

The invention discloses a production method of low-condensation point diesel oil. The production method comprises following steps: diesel oil raw material and hydrogen are mixed, an obtained mixture is delivered through at least two hydrogenation reaction zones in series connection successively, wherein along a material flowing direction, each hydrogenation reaction zone comprises a hydrogenation modification catalyst bed layer, and a condensation point reducing catalyst composite bed layer filled with a hydrogenation modification isomerization condensation point reducing catalyst and a hydrodewaxing catalyst; a reaction effluent obtained from the last hydrogenation reaction zone is subjected to separation and fractionation so as to obtain low-condensation point diesel oil. According to the production method, temperature reducing of hydrodewaxing processes and temperature increasing of hydrogenation modification processes are combined reasonably, low-condensation point diesel oil is produced, and yield and cetane value of diesel oil are increased at the same time, equipment hot-spot temperature is reduced, running period is prolonged, consumption of cold hydrogen or combustion gas loss of a heating furnace is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing hydrogenated low condensation diesel oil

ActiveCN104611033BGuaranteed yieldReduce hot spot temperatureTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation reactionHeating furnace

The invention discloses a method for producing hydrogenated diesel oil with a low freezing point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, allowing the obtained mixture to sequentially go through at least two serially connected hydrogenation reaction zones, wherein the hydrogenation reaction zones sequentially comprise a pour point reduction modified catalyst composite bed layer filled with a hydrodewaxing catalyst and a hydroupgrading catalyst and a hydrodewaxing catalyst bed layer along a material flow direction; and separating a reaction effluent obtained from the last hydrogenation reaction zone, and fractioning to obtain a diesel oil product with a low freezing point. The method reasonably combines the temperature decrease of the hydrodewaxing process and the temperature rise of the hydroupgrading process, so the diesel oil with a low freezing point is produced, the yield and the cetane value of the diesel oil are improved, the hot spot temperature of a device is reduced, and the running period is prolonged; and the consumption of cold hydrogen or the combustion gas loss of a heating furnace is reduced, so the operating cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing hydrogenated low-condensation diesel oil by grading technology

ActiveCN103805251BLow costRealize comprehensive utilizationTreatment with hydrotreatment processesHydrogenation reactionSulfur

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing low-condensation diesel oil using catalyst grading technology

ActiveCN103805257BLow yieldGuaranteed yieldTreatment with hydrotreatment processesHydrogenation reactionSulfur

The invention discloses a method for producing diesel oil with a low condensation point by catalyst gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-refining dewaxing catalyst composite bed layer filled with a mixture of a hydro-refining catalyst and a hydro-upgrading isodewaxing catalyst, and a hydrodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing low-condensation diesel oil using catalyst grading technology

ActiveCN103805237BLow costRealize comprehensive utilizationTreatment with hydrotreatment processesHydrogenation reactionSulfur

The invention discloses a method for producing diesel oil with a low condensation point by catalyst gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydrodewaxing catalyst bed layer, and a hydro-refining dewaxing catalyst composite bed layer filled with a mixture of a hydro-refining catalyst and a hydro-upgrading isodewaxing catalyst; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of production method of low condensation diesel oil

ActiveCN104611027BGuaranteed yieldLow costTreatment with hydrotreatment processesFractionationOperating cost

The present invention discloses a low freezing point diesel fuel production method. According to the low freezing point diesel fuel production method, a diesel fuel raw material and hydrogen gas are mixed and then sequentially pass through at least two hydrogenation reaction zones connected in series, wherein each hydrogenation reaction zone sequentially comprises a hydrodewaxing catalyst bed layer and a composite catalyst bed layer filled with a hydrodewaxing catalyst and a hydro-upgrading isodewaxing catalyst in a mixed manner according to the material flowing direction; and the reaction effluent obtained from the last hydrogenation reaction zone is subjected to separation and fractionation to obtain the low freezing point diesel fuel product. With the method of the present invention, the temperature increase of the hydro-upgrading dewaxing process and the temperature decrease during the hydrodewaxing process are subjected to reasonable combination utilization, such that the low freezing point low-sulfur diesel fuel is produced while the diesel fuel yield and the cetane number are increased, the hot spot temperature of the device is reduced, and the operation period is prolonged; and the cold hydrogen consumption or the heating furnace fuel gas loss is reduced, and the operating cost is further saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of production method of low-condensation high-quality diesel oil

ActiveCN103805260BQuality assuranceGuaranteed yieldTreatment with hydrotreatment processesCombustionSulfur

Owner:CHINA PETROLEUM & CHEM CORP +1

Side airbag for vehicle

InactiveCN107310520AReduce unexpandedImprove unwinding speedPedestrian/occupant safety arrangementEngineeringAirbag

A side airbag for a vehicle is provided. The side airbag includes an airbag cushion and a diffuser that is configured to diffuse gas within the interior of the airbag cushion. A vent aperture is configured to communicate within an interior of the airbag cushion to an exterior of the airbag cushion. A first seam line is formed in a shape that obstructs the vent aperture.

Owner:HYUNDAI MOTOR CO LTD

Method for producing low condensation diesel fuel by grading technology

ActiveCN103805266BGuaranteed yieldAdaptableTreatment with hydrotreatment processesFractionationRaw material

The invention discloses a method for producing diesel oil with a low condensation point by gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a dewaxing catalyst composite bed layer filled with a mixture of a hydro-upgrading isodewaxing catalyst and a hydrodewaxing catalyst, and a hydro-upgrading isodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Intelligent monitoring device for gas meter mainboard

PendingCN105716694AReal-time monitoring of running statusProtect interestsTesting/calibration apparatusElectric machineryEngineering

The invention relates to an intelligent monitoring device for a gas meter mainboard. The intelligent monitoring device comprises an electro-mechanical transformation module, a master control panel, an intelligent monitoring module, a motor valve and a display module, wherein a collected signal output end of the electro-mechanical transformation module is respectively connected with collected signal input ends of the master control module and the intelligent monitoring module through wires; a first signal output end of the master control panel is connected with a first signal input end of the intelligent monitoring module through the wire; a second signal output end of the master control panel is connected with a second signal input end of the motor valve through the wire; a third signal output end of the master control panel is connected with the display module through the wire; a signal output end of the intelligent monitoring module is connected with a first signal input end of the motor valve through the wire. The intelligent monitoring device provided by the invention can be used for monitoring the running state of the gas meter, timely cutting off a fuel gas passage, effectively reducing gas loss phenomena and greatly reducing the loss and production management problems of the gas company.

Owner:LIAONING HANGXUXING IOT INSTR TECH CO LTD

A kind of production method of lubricating oil base oil

ActiveCN104611035BAdaptableRealize comprehensive utilizationTreatment with hydrotreatment processesLubricant compositionFractionationOperating cost

The present invention provides a lubricating oil base oil production method. According to the method, a wax oil raw material and hydrogen gas are mixed and then sequentially pass through at least two hydrogenation reaction zones connected in series, wherein each hydrogenation reaction zone sequentially comprises a hydrodewaxing catalyst bed layer and a dewaxing cracking catalyst composite bed layer filled with a hydrodewaxing catalyst and a hydrocracking catalyst in a mixed manner according to the material flowing direction; and the reaction effluent obtained from the last hydrogenation reaction zone is subjected to separation and fractionation to obtain the lubricating oil base oil, the white oil and other products. With the method of the present invention, the temperature decrease during the hydrodewaxing process and the temperature increase during the hydrogenation process are subjected to reasonable combination utilization, such that the low freezing point lubricating oil base oil is produced while the viscosity index is increased, the hot spot temperature of the device is reduced, and the operation period is prolonged; and the cold hydrogen consumption or the heating furnace fuel gas loss is reduced, and the operating cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for production hydrogenation of low freezing point diesel fuel

ActiveCN104611045AReduce hot spot temperatureGuaranteed yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsChemistryHeating furnace

The present invention discloses a production method for hydrogenation of a low freezing point diesel fuel. According to the method, a diesel fuel raw material and hydrogen gas are mixed and then sequentially pass through at least two hydrogenation reaction zones connected in series, wherein each hydrogenation reaction zone sequentially comprises a hydrodewaxing catalyst bed layer and a composite catalyst bed layer filled with a hydrodewaxing catalyst and a hydro-upgrading catalyst in a mixed manner according to the material flowing direction; and the reaction effluent obtained from the last hydrogenation reaction zone is subjected to separation and fractionation to obtain the low freezing point diesel fuel product. With the method of the present invention, the temperature decrease during the hydrodewaxing process and the temperature increase during the hydro-upgrading process are subjected to reasonable combination utilization, such that the low freezing point low-sulfur diesel fuel is produced while the diesel fuel yield and the cetane number are increased, the hot spot temperature of the device is reduced, and the operation period is prolonged; and the cold hydrogen consumption or the heating furnace fuel gas loss is reduced, and the operating cost is further saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of low-condensation diesel oil

ActiveCN103805262BAdaptableRealize comprehensive utilizationTreatment with hydrotreatment processesSulfurHydrogenation reaction

The invention discloses a production method of diesel oil with a low condensation point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a dewaxing catalyst composite bed layer filled with a mixture of a hydro-upgrading isodewaxing catalyst and a hydrodewaxing catalyst, and a hydro-upgrading catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature decrease of the hydrodewaxing process with the temperature increase of the hydro-upgrading process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Adaptive wall-climbing robot for complex environment

The invention discloses an adaptive wall-climbing robot facing complex environments, which comprises a robot body, a multi-porous self-adaptive suction cup, a gas distribution mechanism, and a vacuum generating mechanism. Porous flexible adsorption plate, bottom plate, differential pressure one-way valve cavity, rectangular boss, vacuum adsorption tube, fixed plate, slider, large anti-skid nut, fixed bolt, small anti-skid nut, air distribution mechanism including air distribution groove, track During the movement, it is always fixed by the negative pressure in the air distribution groove, and is close to the bottom of the air distribution groove. The porous self-adaptive suction cup on the track moves with the track to dynamically seal the two ends of the air distribution groove. The vacuum generating mechanism is used Due to the negative pressure generated by vacuuming during adsorption, it can realize the full contact between the multi-porous self-adaptive suction cup on the wall-climbing robot and the uneven surface, and the fixed-point distribution of the suction cup in contact with the ground can effectively reduce the gas loss of the vacuum generator. .

Owner:CENT SOUTH UNIV

Production method of hydrogenated low-condensation diesel oil

ActiveCN103805252BGuaranteed yieldRealize comprehensive utilizationTreatment with hydrotreatment processesFractionationChemistry

The invention discloses a production method of hydrogenated diesel oil with a low condensation point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-upgrading dewaxing catalyst composite bed layer filled with a mixture of a hydro-upgrading catalyst and a hydrodewaxing catalyst, and a hydro-upgrading isodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature decrease of the hydrodewaxing process with the temperature increase of the hydro-upgrading process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com