Shale gas content measurement device and method

A technology of shale gas content and testing equipment, which is applied in the field of oil and gas exploration and development, can solve the problems of gas escape, long desorption period, and cannot meet the requirements of fast acquisition of shale gas content, and achieve accurate test results, improve accuracy, Effect of reducing gas loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

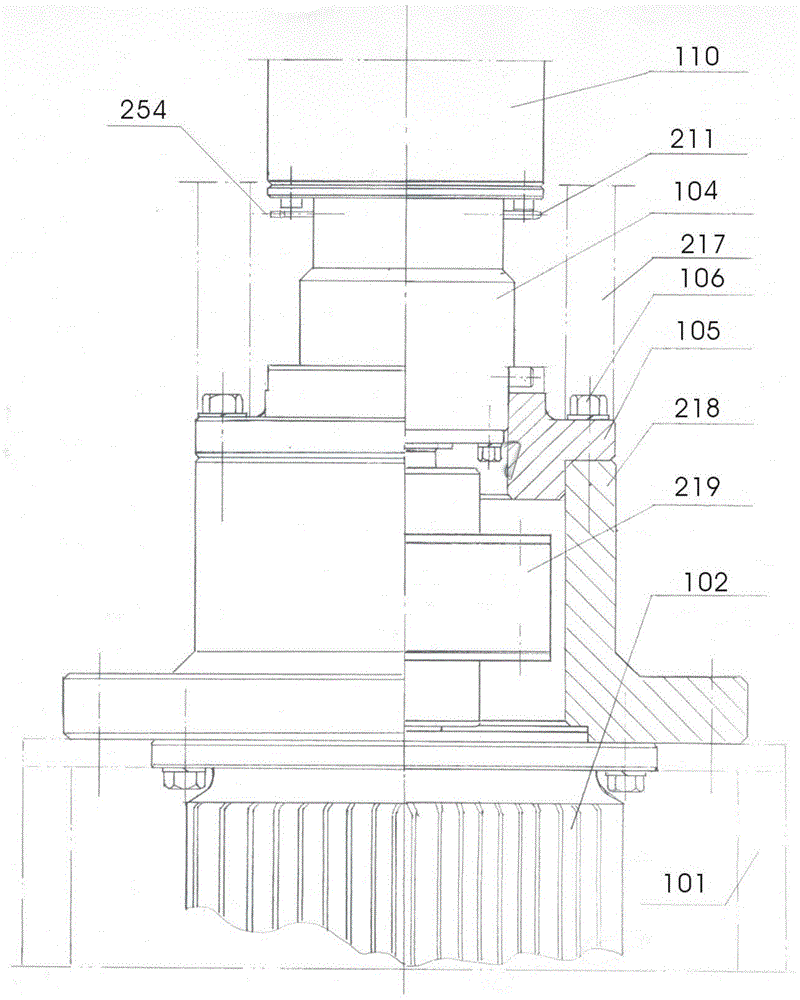

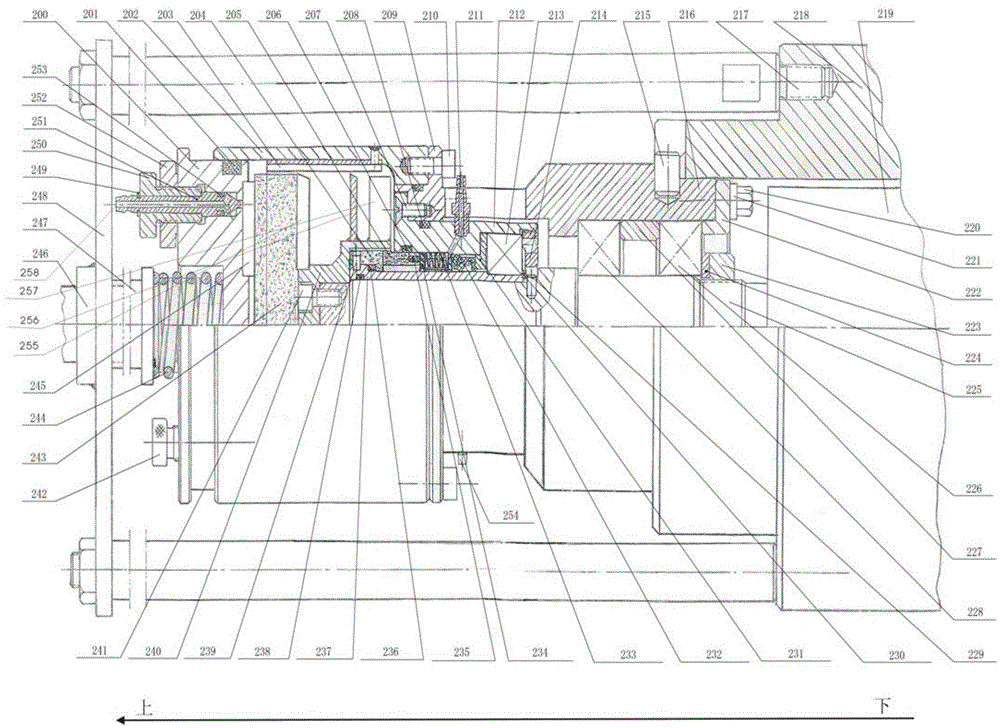

[0037] Such as figure 1 Shown is a specific embodiment of the shale gas content testing device of the present invention. In this embodiment, the testing device includes a fixed base 218, a motor 102, a shaft coupling 219, an intermediate sleeve 105, and a sealed broken sample cylinder 110, wherein the fixed base 218 is fixed on the instrument support 101 for fixing the motor 102 and Broken sample cylinder support seat 104, the output bearing of motor 102 is connected with the stirring shaft 225 in the sealed crushed sample cylinder 110 through coupling 219, and the stirred shaft 225 rotates under the drive of motor 102; Sealed broken sample cylinder 110, its cylinder It is connected with the broken sample cylinder support base 104 in the fixed base. One end of the middle sleeve 105 is used to fix the supporting seat 104 of the crushed sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com