Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Overcomes the disadvantage of needing to be installed in a joint position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freedom degree changeable link mechanism carrying operation mechanical arm containing revolute pair locking device

InactiveCN106799731ALess freedomReduce weightProgramme-controlled manipulatorConveyor partsLocking mechanismControl theory

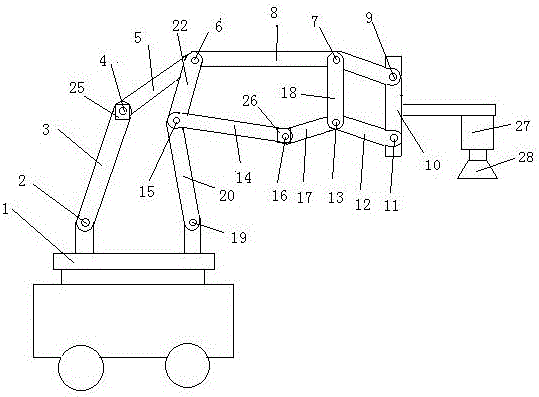

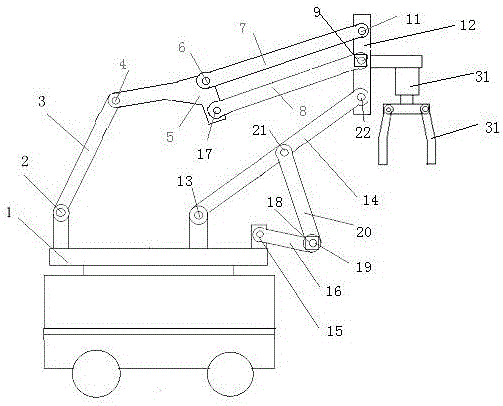

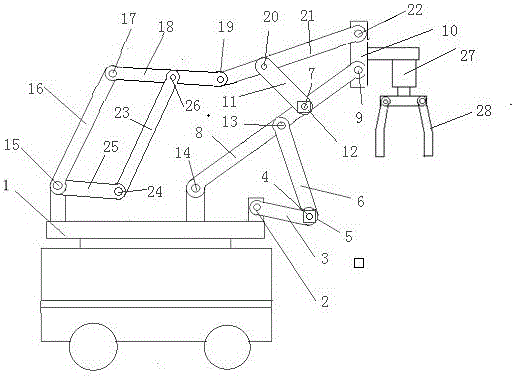

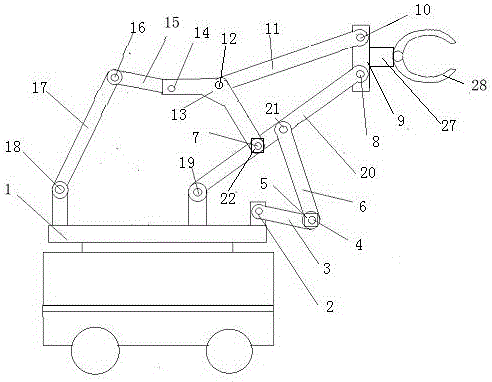

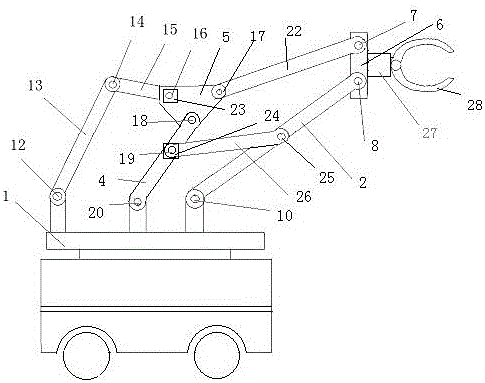

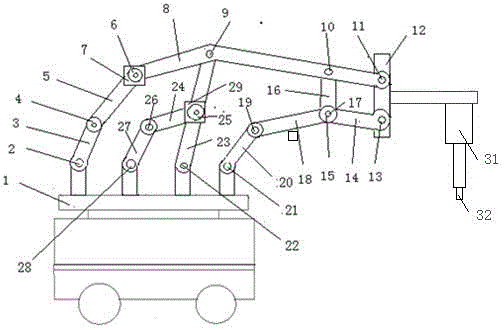

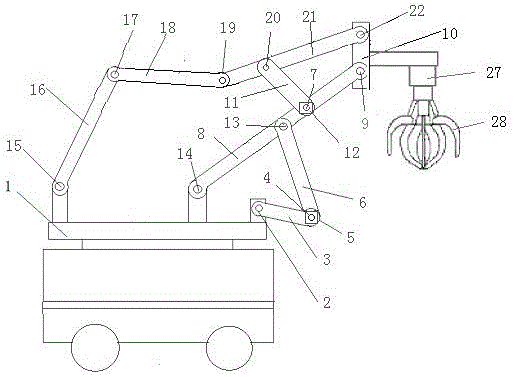

A freedom degree changeable link mechanism carrying operation mechanical arm containing a revolute pair locking device comprises a base 1, a big arm telescoping mechanism, a lower arm lifting mechanism, a wrist connecting rod keeping mechanism, a wrist 27, a vacuum suction cup 28, a servo drive device, a first locking device 25 and a second locking device 26. The big arm telescoping mechanism is composed of a fourth connecting rod 5, a first drive rod 3, a second drive rod 20 and a first connecting rod 22. The keeping mechanism is composed of a second connecting rod 17, a keeping connecting rod 18 and a big arm 8. The first locking device 25 is arranged on a second revolute pair 4, and the second locking mechanism 26 is arranged on a tenth revolute pair 16. The servo drive device comprises a first servo motor and a second servo motor which are connected with the first drive rod 3 and the second drive rod 20 to drive the first drive rod 3 and the second drive rod 20 to rotate. The freedom degree changeable link mechanism carrying operation mechanical arm adopts a freedom degree changeable connecting rod transmission mechanism to replace traditional hydraulic transmission, and the defects that a hydraulic carrying operation mechanical arm is complex in hydraulic system and prone to oil leakage are overcome.

Owner:GUANGXI UNIV

Connecting rod type variable-freedom-degree welding mechanical arm driven by servo motor

InactiveCN106607657AReduce weightSmall moment of inertiaWelding/cutting auxillary devicesAuxillary welding devicesEngineeringControl theory

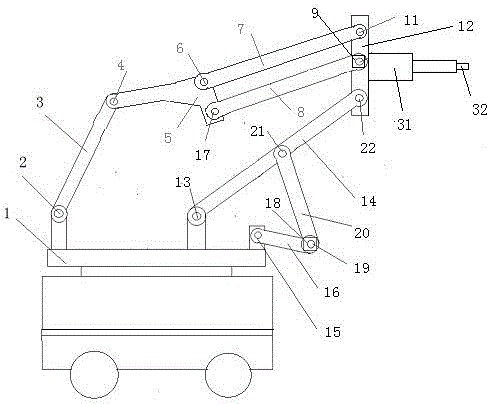

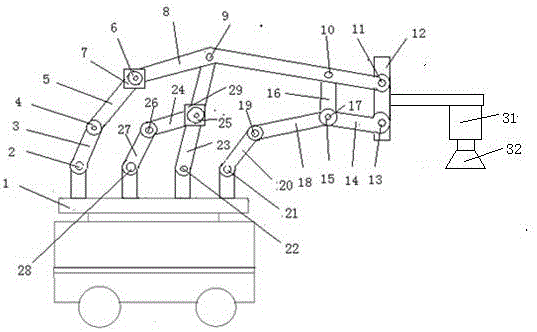

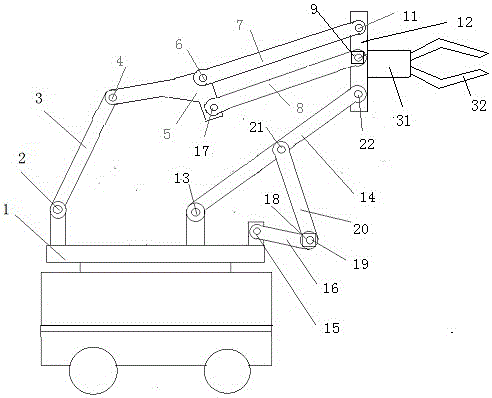

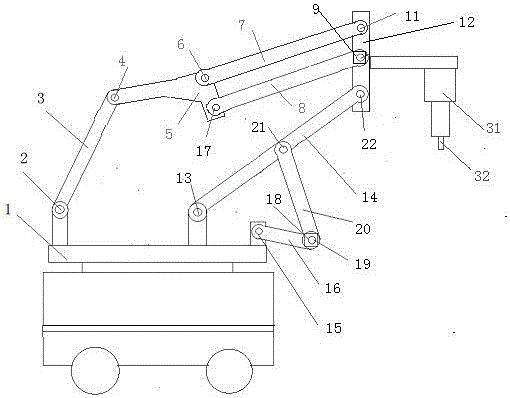

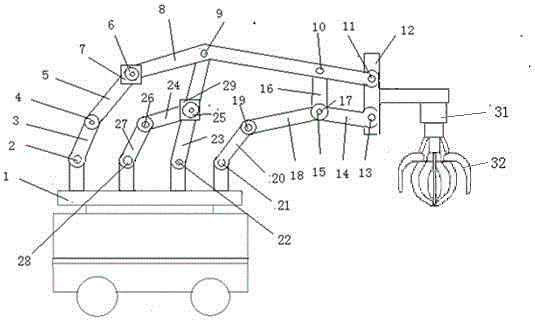

The invention discloses a connecting rod type variable-freedom-degree welding mechanical arm driven by a servo motor. The connecting rod type variable-freedom-degree welding mechanical arm is characterized by comprising a base 1, a large arm lifting mechanism, a wrist connecting rod pitching mechanism, a wrist 31, a welding gun 32, a servo drive device, a first locking device 9 and a second locking device 19; the large arm lifting mechanism is composed of a large arm 14 and a lifting mechanism; the large arm 14 is connected to the base 1 through a seventh rotation pair 13; the servo drive device comprises the first servo motor which is connected with a drive rod 3 to drive the drive rod 3 to rotate; and the first locking device 9 and the second locking device 19 conduct locking in an electromagnetic manner. According to the connecting rod type variable-freedom-degree welding mechanical arm, a novel connecting rod transmission mechanism is used for replacing traditional hydraulic transmission, the defects that a hydraulic welding mechanical arm hydraulic system is complex, oil leakage is likely to happen, and the requirement for machining precision is high are overcome; and due to the fact that the locking devices are adopted on rotation pairs, one drive rod can be used for achieving welding work of two freedom degrees, and the number of motors for use is reduced.

Owner:GUANGXI UNIV

Variable-freedom-degree multi-connection-rod coating operation mechanical arm driven by servo motor

InactiveCN106607865ASimplify complexityReduce weightProgramme-controlled manipulatorSpraying apparatusSpray nozzleControl theory

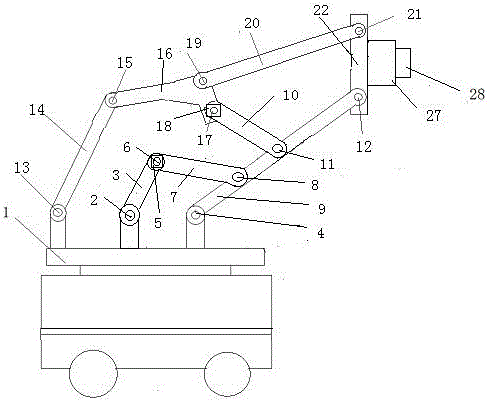

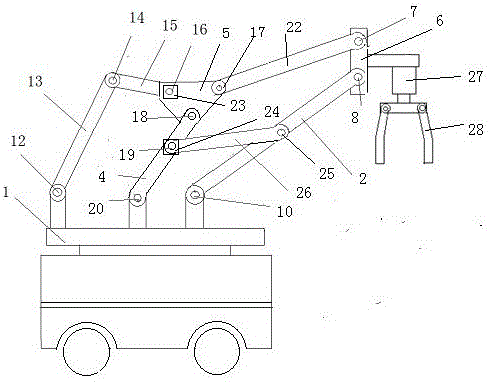

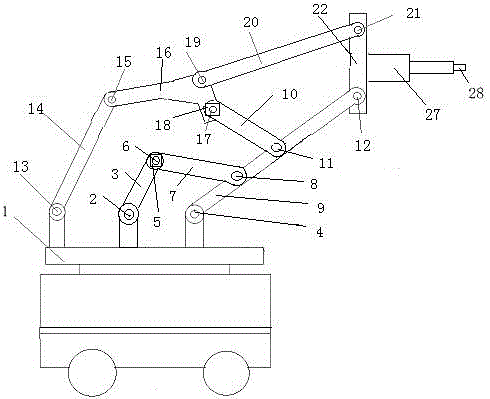

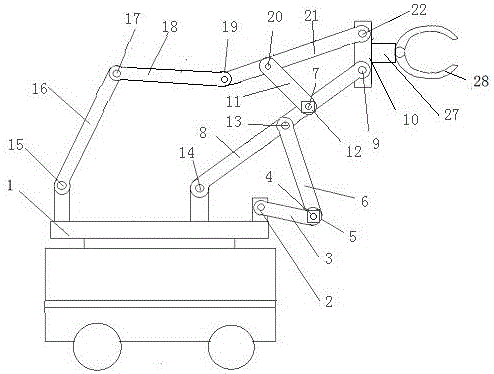

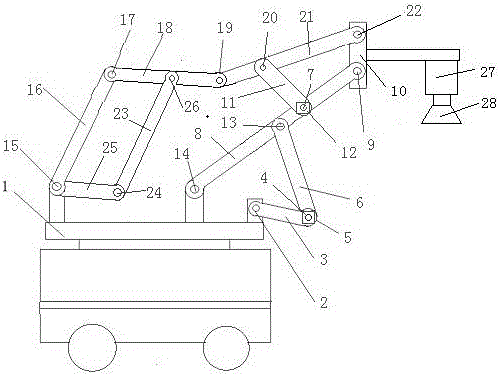

A variable-freedom-degree multi-connection-rod coating operation mechanical arm driven by a servo motor comprises a base 1, a big arm ascending and descending mechanism, a wrist connection rod pitching mechanism, a wrist 27, a spray nozzle 28, a servo drive device, a first locking device 5 and a second locking device 18. The big arm ascending and descending mechanism is composed of the big arm 9 and an ascending and descending mechanism. The wrist connection rod pitching mechanism is composed of a wrist connection rod 22 and a pitching mechanism. The first locking device 5 is installed on a third rotation pair 6. The second locking device 18 is installed on a seventh rotation pair 17. The first locking device 5 and the second locking device 18 conduct locking at the appropriate moment according to different working conditions. The servo drive device comprises the first servo motor, wherein the first servo motor is connected with a first driving rod 14 so as to drive the first driving rod 14 to rotate. The first locking device 5 and the second locking device 18 conduct locking in an electromagnetic manner. The variable-freedom-degree multi-connection-rod coating operation mechanical arm driven by the servo motor overcomes defects that a hydraulic system of a hydraulic machine is complicated, high in machining accuracy requirement and prone to leaking oil; and two-freedom-degree operation is achieved in the manner that the locking devices are arranged on the rotation pairs, and the number of the adopted servo drive motor is smaller than the number of the freedom degrees of a linkage mechanism of the coating operation mechanical arm.

Owner:GUANGXI UNIV

Connecting rod type variable-degree-of-freedom painting mechanical arm driven by servo motor

InactiveCN106607916ALess freedomSimplify complexityProgramme-controlled manipulatorDegrees of freedomTwo degrees of freedom

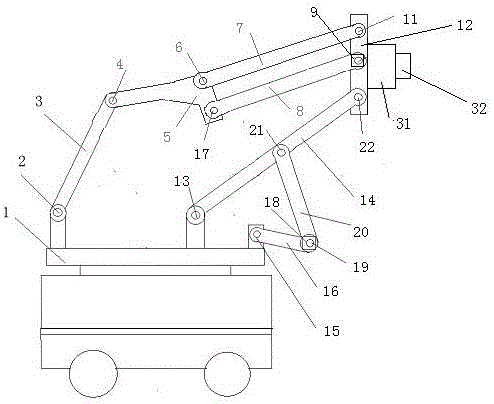

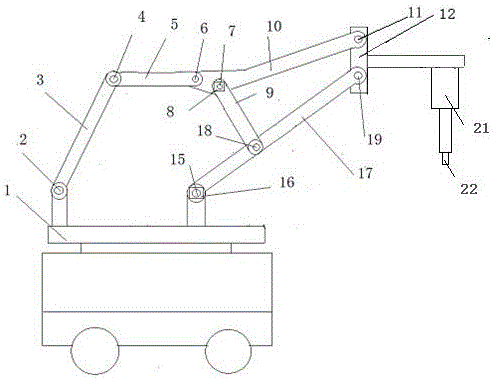

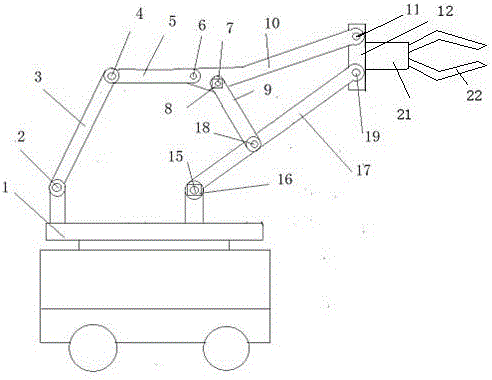

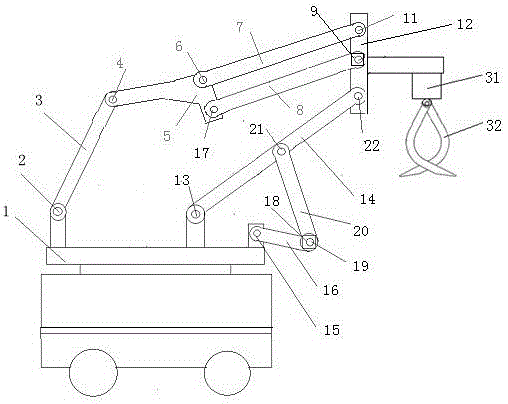

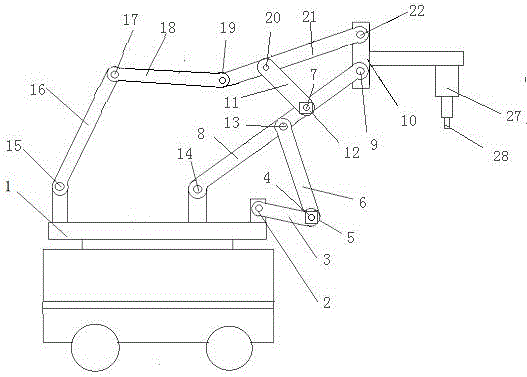

The invention relates to a connecting rod type variable-degree-of-freedom painting mechanical arm driven by a servo motor. The connecting rod type variable-degree-of-freedom painting mechanical arm is characterized by comprising a base 1, a large arm lifting mechanism, a wrist connecting rod pitching mechanism, a wrist 31, a nozzle 32, a servo driving device, a first locking device 9 and a second locking device 19, wherein the large arm lifting mechanism is composed of a large arm 14 and a lifting mechanism, the large arm 14 is connected to the base 1 by virtue of a seventh revolving pair 13, the servo driving device comprises a first servo motor which is connected with a driving rod 3 so as to drive the first servo motor to rotate, and the first locking device 9 and the second locking device 19 are locked in an electromagnetic mode. According to the connecting rod type variable-degree-of-freedom painting mechanical arm, a novel connecting rod transmission mechanism is used for replacing traditional hydraulic transmission, and the defects of complex hydraulic system, easiness in oil leakage, high machining precision requirement and the like of a hydraulic painting mechanical arm are overcome; the locking devices are installed on revolving pairs, so that the two-degree-of-freedom painting operation can be realized only by using one driving rod, and the use number of motors is reduced.

Owner:GUANGXI UNIV

Connecting rod type variable freedom degree fodder stacking mechanical arm driven by servo motor

InactiveCN106608541ALess freedomSimplify complexityStacking articlesDe-stacking articlesElectric machineryManipulator

A connecting rod type variable freedom degree fodder stacking mechanical arm driven by a servo motor is characterized by comprising a base 1, a big arm lifting mechanism, a wrist connecting rod pitching mechanism, a wrist 31, a paw 32, a servo drive device, a first locking device 9 and a second locking device 19; the big arm lifting mechanism is composed of a big arm 14 and a lifting mechanism, and the big arm 14 is connected to the base 1 through a seventh rotation pair 13; the servo drive device comprises a first servo motor which is connected with a drive rod 3 so as to drive the drive rod 3 to rotate; and the first locking device 9 and the second locking device 19 conduct locking in an electromagnetic manner. A novel connecting rod transmission mechanism is adopted in the connecting rod type variable freedom degree fodder stacking mechanical arm for replacing traditional hydraulic transmission, and the defects that a hydraulic fodder stacking mechanical arm hydraulic system is complex, oil leakage is likely to happen, and the machining precision requirement is high are overcome; the locking devices are adopted in rotation pairs so that the two-freedom-degree fodder stacking operation can be achieved by utilizing one drive rod, and the number of adopted motors is reduced.

Owner:GUANGXI UNIV

Servo drive rod type variable-degree-of-freedom mechanical arm for transport operation

InactiveCN106695756ALess freedomReduce weightProgramme-controlled manipulatorConveyor partsThree degrees of freedomEngineering

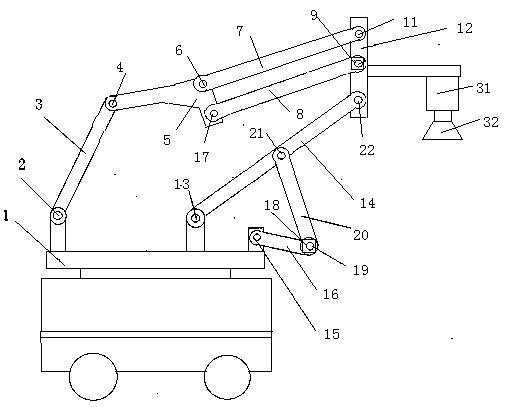

The invention discloses a servo drive rod type variable-degree-of-freedom mechanical arm for transport operation. The servo drive rod type variable-degree-of-freedom mechanical arm for transport operation comprises a base, a big arm telescopic mechanism, a lifting mechanism, a wrist connecting rod pitching mechanism, a wrist, a vacuum suction cup, a servo drive device and two locking devices. The big arm telescopic mechanism comprises a first connecting rod, a second connecting rod and a third connecting rod, wherein one end of the first connecting rod is connected with the base through a first rotating pair, the other end of the first connecting rod is connected with one end of the third connecting rod through a third rotating pair, the other end of the third connecting rod is connected with the second connecting rod through a fourth rotating pair, one end of the second connecting rod is connected with the base through a second rotating pair, and the other end of the second connecting rod is connected with a big arm through a fifth rotating pair. The locking devices are installed on the corresponding rotating pairs. A connecting rod transmission mechanism is adopted to replace a traditional hydraulic transmission mode, the defects that a hydraulic system of a hydraulic transport operation mechanical arm is complex, prone to oil leakage and the like can be overcome, and as the locking devices are installed on the corresponding rotating pairs, transport operation of three degrees of freedom can be achieved through two driving rods.

Owner:GUANGXI UNIV

Multi-connecting-rod variable-freedom-degree feed stacking manipulator driven by servo motors

InactiveCN106625559ALess freedomSimplify complexityProgramme-controlled manipulatorJointsEngineeringManipulator

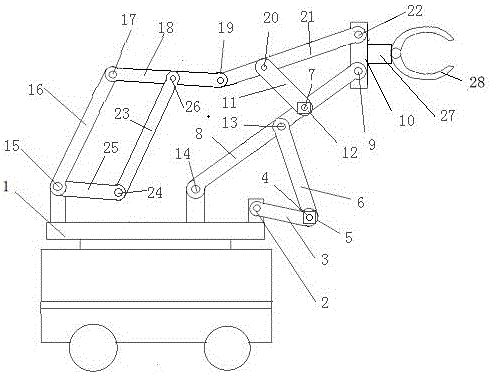

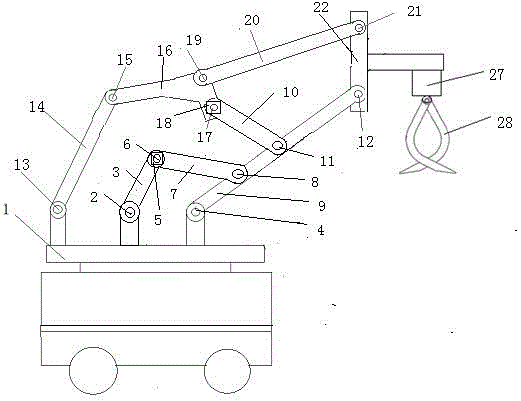

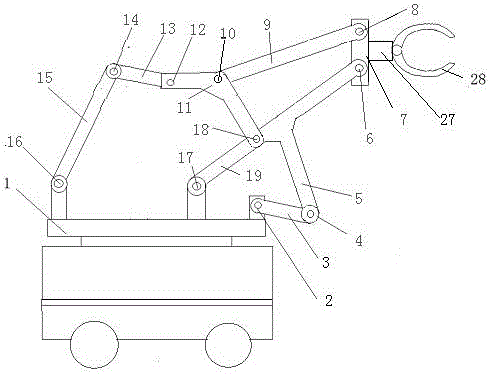

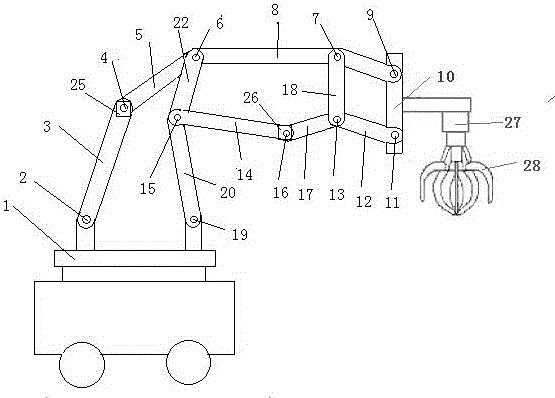

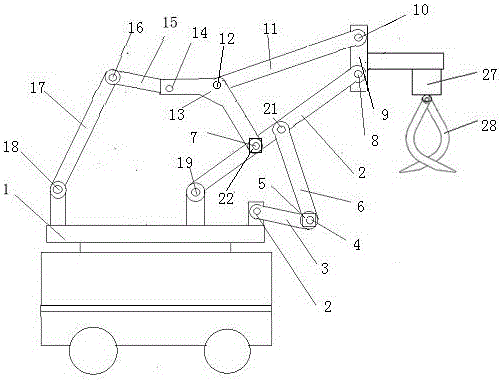

The invention discloses a multi-connecting-rod variable-freedom-degree feed stacking manipulator driven by servo motors. The multi-connecting-rod variable-freedom-degree feed stacking manipulator is composed of a base 1, a driving rod 13, a first connecting rod 15, a first connecting piece 5, a fourth connecting rod 4, a big arm 2, a wrist connecting rod 6, a second connecting rod 22, a third connecting rod 26, a wrist 27, a gripper 28, a servo driving device, a first locking device 23 and a second locking device 24; The big arm 2 is connected to the base through a first revolute pair 10; the first locking device 23 is mounted on a seventh revolute pair 16, and the second locking device 24 is mounted on an eleventh revolute pair 19; the servo driving device comprises a first servo motor connected with the driving rod 13 to drive the driving rod 13 to rotate; and the first locking device 23 and the second locking device 24 are used for locking in an electromagnetic way. According to the multi-connecting-rod variable-freedom-degree feed stacking manipulator, a hydraulic mechanism is replaced with a connecting rod driving mechanism, so that the defects that the hydraulic mechanism is prone to oil leakage, complex in mechanism and the like are overcome; the locking devices are adopted by the revolute pairs for adapting to different working conditions; and the amount of the used motors is smaller than the freedom degree of the mechanism.

Owner:GUANGXI UNIV

Servo motor driven variable degree-of-freedom connecting mechanism for simple oxygen-acetylene cutting machine

InactiveCN106607635AImprove smoothness and reliabilityNo cumulative errorWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to a servo motor driven variable degree-of-freedom connecting mechanism for a simple oxygen-acetylene cutting machine. The mechanism comprises a base 1, a large arm 17, a clamp holder connecting rod pitch mechanism, a clamp holder 21, a cutting gun 22, a servo driving device, a first locking device 8 and a second locking device 16; the clamp holder connecting rod pitch mechanism is composed of clamp holder connecting rod and a pitch mechanism, the clamp holder connecting rod is connected to the large arm 17 through a ninth revolute pair 19 and a tenth revolute pair 20 which are coaxial, the pitch mechanism is composed of a driving piece 3, a first connecting rod 5, a second connecting rod 10 and a third connecting rod 9, and the first locking device 8 and the second locking device 16 are separately mounted on a fourth revolute pair 7 and the seventh revolute pair 15 and timely lock according to different working conditions of the mechanism; the first locking device 8 and the second locking device 16 lock in an electromagnetic mode. The mechanism provided by the invention overcomes the defect that driving motors of open chain structures need to be mounted in joint positions, and the quantity of used controllable driving motors is smaller than the degree of freedom of an oxygen-acetylene cutting connecting mechanism.

Owner:GUANGXI UNIV

Feed stacking mechanism arm with variable degree-of-freedom link mechanism

InactiveCN106607906ALess freedomReduce weightProgramme-controlled manipulatorDegrees of freedomEngineering

The invention discloses a feed stacking mechanism arm with a variable degree-of-freedom link mechanism. The feed stacking mechanism arm comprises a base 1, a big arm lifting mechanism, a wrist link pitch mechanism, a wrist 27, claws 28, a servo driving device, a first locking device 5 and a second locking device 12, wherein the big arm lifting mechanism comprises a big arm 8, a fourth link 3 and a fifth link 6; the wrist link pitch mechanism comprises a driving rod 16, a first link 18, a second link 21 and a third link 11; the first locking device 5 and the second locking device 12 are separately arranged on an eleventh revolute pair 4 and an eighth revolute pair 7, and can be locked in due time according to different working conditions of a feed stacking mechanical arm structure; the servo driving device comprises a first servo motor which is connected with the driving rod 16, so that the servo motor is driven to rotate; and the first locking device 5 and the second locking device 12 are locked by adopting an electromagnetic mode. According to the feed stacking mechanism arm disclosed by the invention, the two-degree-of-freedom feed stacking operation can be realized by only using one driving rod, so that the use amount of motors is reduced and the construction cost of the feed stacking mechanical arm structure is reduced.

Owner:GUANGXI UNIV

Mechanical arm with locking-device-contained motion range changeable link mechanism and used for assembling work

InactiveCN106737715ALess freedomReduce weightProgramme-controlled manipulatorMetal working apparatusControl theoryElectromagnetism

Disclosed is a mechanical arm with a locking-device-contained motion range changeable link mechanism and used for assembling work. The mechanical arm is characterized by comprising a base 19, a second driving rod 21, a second connecting rod 2, an upper arm 4, a wrist connecting rod 7, a first driving rod 17, a big arm 9, a fourth connecting rod 14, a first connecting rod 12, a wrist 27, an assembling clamping paw 28, a servo driving device and a third connecting rod 10; a first electromagnetic locking device 23 is installed on a second revolute pair 15; a second electromagnetic locking device 24 is installed on a tenth revolute pair 3; the servo driving device comprises a first servo motor and a second servo motor, and the first servo motor and the second servo motor are connected to the first driving rod 17 and the second driving rod 21 to drive the first driving rod 17 and the second driving rod 21 to rotate; the first electromagnetic locking device 23 and the second electromagnetic locking device 24 are locked through an electromagnetism method to jointly complete motion of rising and falling of the big arm and pitching of the wrist connecting rod and the wrist and the like, and to jointly achieve the assembling work of the assembling clamping paw 28. According to the mechanical arm with the locking-device-contained motion range changeable link mechanism and used for the assembling work, the motion range changeable link driving mechanism is utilized to replace a traditional hydraulic drive, and the shortcomings that a hydraulic pressure assembling work mechanical arm is complicated in hydraulic system and prone to oil leakage are overcome.

Owner:GUANGXI UNIV

Timber grab with freedom-degree-variable linkage mechanism

InactiveCN106629021ALess freedomReduce weightConveyorsConveyor partsEngineeringMechanical engineering

The invention provides a timber grab with a freedom-degree-variable linkage mechanism. The timber grab comprises a base (1), a large arm lifting mechanism, a wrist linkage pitch mechanism, a wrist (27), a paw (28), a servo driving device, a first locking device (5) and a second locking device (12); the large arm lifting mechanism comprises a large arm (8), a fourth connecting rod (3) and a fifth connecting rod (6); the wrist linkage pitch mechanism comprises a driving rod (16), a first connecting rod (18), a second connecting rod (21) and a third connecting rod (11); the first locking device (5) and the second locking device (12) are installed on an eleventh rotating pair (4) and an eighth rotating pair (7) correspondingly and can timely lock according to different work conditions of a timber grabbing mechanism; and the servo driving device comprises a first servo motor which is connected with the driving rod (16) to drive the driving rod (16) to rotate, and the first locking device (5) and the second locking device (12) lock in an electromagnetic mode. According to the timber grab with the freedom degree variable linkage mechanism, timber grabbing operation of two freedom degrees can be achieved through one driving rod (16), so that the usage quantity of the motors is reduced, and construction cost of the timber grabbing mechanism is lowered.

Owner:GUANGXI UNIV

Variable degree-of-freedom multilink welding machine driven by servo motor

InactiveCN106607653AReduce weightSmall moment of inertiaWelding/cutting auxillary devicesAuxillary welding devicesDegrees of freedomEngineering

The invention discloses a variable degree-of-freedom multilink welding machine driven by a servo motor. The variable degree-of-freedom multilink welding machine comprises a base 1, a big arm lifting mechanism, a wrist link pitch mechanism, a wrist 27, a welding gun 28, a servo driving device, a first locking device 5 and a second locking device 18, wherein the big arm lifting mechanism consists of a big arm 9 and a lifting mechanism; the wrist link pitch mechanism consists of a wrist link 22 and a pitch mechanism; the first locking device 5 and the second locking device 18 are separately arranged on a third revolute pair 6 and a seventh revolute pair 17, and are locked in due time according to different working conditions; the servo driving device comprises a first servo motor which is connected with a first driving rod 14, so that the first servo motor is driven to rotate; and the first locking device 5 and the second locking device 18 are locked by adopting an electromagnetic mode. According to the variable degree-of-freedom multilink welding machine disclosed by the invention, the defects that a hydraulic system of a hydraulic machine is complex, is high in requirement on processing precision and easily leaks oil are overcome; the locking devices are adopted for the revolute pairs to realize the two-degree-of-freedom operation; and the amount of the used servo drive motors is smaller than the degree-of-freedom of a link mechanism of a welding mechanism arm.

Owner:GUANGXI UNIV

Servo driving rod type variable-freedom-degree simple mechanical arm for assembling work

InactiveCN106671128ALess freedomReduce weightProgramme-controlled manipulatorArmsElectric machineRobotic arm

A servo driving rod type variable-freedom-degree simple mechanical arm for assembling work comprises a base (1), a large arm (17), a wrist connecting rod pitching mechanism, a wrist (21), an assembling clamping gripper (22), a servo driving device, a first locking device (8) and a second locking device (16); the wrist connecting rod pitching mechanism is composed of a wrist connecting rod and a pitching mechanism, the wrist connecting rod is connected to the large arm (17) through a ninth rotation pair (19) and a tenth rotation pair (20) coaxial with the ninth rotation pair (19), and the pitching mechanism is composed of a driving piece (3), a first connecting rod (5), a second connecting rod (10) and the third connecting rod (9); the first locking device (8) and the second locking device (16) are installed on a fourth rotation pair (7) and a seventh rotation pair (15) correspondingly, so that locking is conducted at the right time according to different work conditions of a mechanism; and electromagnetic locking is achieved through the first locking device (8) and the second locking device (16). According to the servo driving rod type variable-freedom simple mechanical arm for the assembling work, the defect that driving motors of a chain-opening structure all need to be installed on the joint position is overcome, and the number of the used controllable driving motors is smaller than the degree of freedom of a mechanical arm connecting rod mechanism for assembling work.

Owner:GUANGXI UNIV

Variable freedom degree connecting rod type timber grab driven by servo motor

InactiveCN106608525AImprove smoothness and reliabilityNo cumulative errorConveyorsConveyor partsControl theoryServo drive

A variable freedom degree connecting rod type timber grab driven by a servo motor comprises a base 1, a big arm lifting mechanism, a wrist connecting rod pitching mechanism, a wrist 27, a paw 28, a servo drive device, a first locking device 5 and a second locking device 22. The big arm lifting mechanism comprises a big arm 20, a first connecting rod 3 and a second connecting rod 6. The wrist connecting rod pitching mechanism comprises a drive rod 17, a third connecting rod 15, a connecting piece 13 and a fourth connecting rod 11. The first locking device 5 and the second locking device 22 are arranged on a second rotation pair 4 and a fifth rotation pair 7 correspondingly. The servo drive device comprises a first servo motor connected with the drive rod 17 so as to drive the drive rod 17 to rotate. The first locking device 5 and the second locking device 22 conduct locking in an electromagnetic manner. The two-freedom-degree timber grabbing operation can be achieved by utilizing one drive rod, the number of adopted motors is reduced, and the construction cost of the timber grabbing mechanism is reduced.

Owner:GUANGXI UNIV

Servo drive rod type variable freedom degree mechanical arm for assembling work

InactiveCN106671129ALess freedomSimplify complexityProgramme-controlled manipulatorArmsRobotic armControl theory

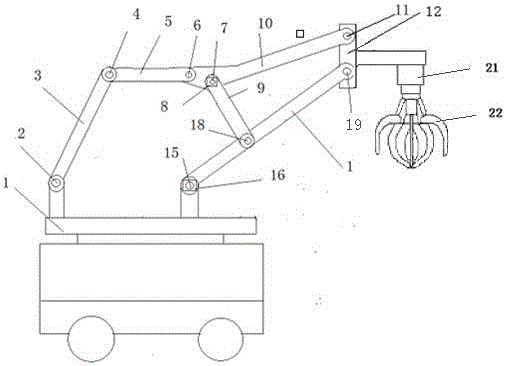

A servo drive rod type variable freedom degree mechanical arm for assembling work is characterized by comprising a base 1, a big arm lifting mechanism, a wrist connecting rod pitching mechanism, a wrist 31, an assembling clamping claw 32, a servo drive device, a first locking device 9 and a second locking device 19; the big arm lifting mechanism is composed of a big arm 14 and a lifting mechanism; the big arm 14 is connected to the base 1 through a seventh rotation pair 13; the servo drive device comprises a first servo motor connected with a drive rod 3 so as to drive the drive rod 3 to rotate; and the first locking device 9 and the second locking device 19 conduct locking in an electromagnetic manner. According to the servo drive rod type variable freedom degree mechanical arm, a novel connecting rod transmission mechanism is adopted for replacing traditional hydraulic transmission, and the defects that a hydraulic assembling operation mechanical arm hydraulic system is complex, prone to oil leakage, high in requirement for machining precision and the like are overcome; and due to the fact that the locking devices are adopted in rotation pairs, two-freedom-degree assembling work can be achieved only by utilizing one drive rod, and the usage number of motors is reduced.

Owner:GUANGXI UNIV

Variable mobility connecting rod mechanism driven by servomotor

InactiveCN106759568ALess freedomSimplify complexityMechanical machines/dredgersElectric machineryEngineering

A variable mobility connecting rod mechanism driven by a servomotor is characterized by comprising a base 1, a large arm lifting mechanism, a wrist connecting rod pitching mechanism, a servo drive device, a first locking device 9 and a second locking device 19; the large arm lifting mechanism consists of a large arm 14 and a lifting mechanism, the large arm 14 is connected on the base 1 by a seventh rotary pair 13, and the servo drive device comprises a first servomotor, which is connected to an active rod 3 to drive the same to rotate; and the first locking device 9 and the second locking device 19 are locked by an electromagnetic manner. The novel connecting rod transmission mechanism is adopted to replace traditional hydraulic transmission, the defects that the hydraulic system of a hydraulic sugarcane grabbing machine is complex, easy for oil leakage, high in machining precision requirement and the like are solved, since the locking devices are adopted on the rotary pair, the sugarcane grabbing operation of two freedom degrees can be realized by using one active rod, and a use number of the electromotor is reduced.

Owner:GUANGXI UNIV

Servo motor driven multi-link mechanism with variable degrees of motion

InactiveCN106826913ALess freedomSimplify complexityProgramme-controlled manipulatorHarvestersMotor driveMulti link

A multi-link mechanism with a variable activity degree driven by a servo motor, comprising: a base 1, a boom lifting mechanism, a wrist link pitching mechanism, a servo drive device, a first locking device 5, and a second locking device 18; The boom lifting mechanism is composed of a boom 9 and a lifting mechanism, the wrist link pitch mechanism is composed of a wrist link 22 and a pitch mechanism, and the first locking device 5 and the second locking device 18 are respectively installed on the On the three rotating pairs 6 and the seventh rotating pair 17, timely locking is performed according to different working conditions; the servo drive device includes a first servo motor, which is connected with the first active lever 14 to drive its rotation; the first locking device 5 and the second locking device 18 are locked electromagnetically. The invention overcomes the disadvantages of complex hydraulic system, high machining accuracy and easy oil leakage, and uses a locking device on the revolving pair to realize two degrees of freedom operations, and the number of servo drive motors used is less than the degrees of freedom of the connecting rod mechanism.

Owner:GUANGXI UNIV

Multi-connecting-rod variable-freedom-degree wood grasping machine provided with servo motors for driving

InactiveCN106609515ALess freedomSimplify complexityMechanical machines/dredgersMechanical engineeringEngineering

The invention provides a multi-connecting-rod variable-freedom-degree wood grasping machine provided with servo motors for driving. The multi-connecting-rod variable-freedom-degree wood grasping machine provided with the servo motors for driving is composed of a base 1, a driving rod 13, a first connecting rod 15, a first connecting piece 5, a fourth connecting rod 4, a big arm 2, a wrist connecting rod 6, a second connecting rod 22, a third connecting rod 26, a wrist 27, a paw 28, a servo driving device, a first locking device 23 and a second locking device 24. The big arm 2 is connected to the base through a first revolute pair 10. The first locking device 23 and the second locking device 24 are mounted on a seventh revolute pair 16 and an eleventh revolute pair 19 correspondingly. The servo driving device comprises the first servo motor, and the first servo motor is connected with the driving rod 13 to drive the driving rod 13 to rotate. The first locking device 23 and the second locking device 24 are locked in an electromagnetic mode. According to the multi-connecting-rod variable-freedom-degree wood grasping machine provided with the servo motors for driving, a connecting-rod transmission mechanism is used for replacing a hydraulic mechanism, and the defects that the hydraulic mechanism is prone to oil leakage, complex and the like are overcome; and since the locking devices are arranged on the revolute pairs, the multi-connecting-rod variable-freedom-degree wood grasping machine can adapt to different working conditions, and the number of the adopted motors is smaller than the freedom degree of the mechanism.

Owner:GUANGXI UNIV

Dual servo motor driven variable-freedom-degree multi-connecting-rod timber grab

A dual servo motor driven variable-freedom-degree multi-connecting-rod timber grab comprises a base 1, a big arm lifting mechanism, a wrist connecting rod pitching mechanism, a wrist 27, a gripper 28, a servo drive device, a first locking device 5 and a second locking device 12. The big arm lifting mechanism comprises a big arm 8, a fourth connecting rod 3 and a fifth connecting rod 6. The wrist connecting rod pitching mechanism comprises a driving rod 16, a first connecting rod 18, a second connecting rod 21 and a third connecting rod 11. The first locking device 5 and the second locking device 12 are mounted on an eleventh rotating pair 4 and an eighth rotating pair 7 correspondingly, and proper locking can be carried out according to different work conditions of a timber grabbing mechanism. The servo drive device comprises a first servo motor, and the first servo motor is connected with the driving rod 16 so as to drive the driving rod 16 to rotate. The first locking device 5 and the second locking device 12 achieve locking through an electromagnetic manner. The timber grab can achieve timber grabbing work of two freedom degrees through only one driving rod, the number of adopted motors is reduced, and the manufacturing cost of the timber grabbing mechanism is reduced.

Owner:GUANGXI UNIV

Dual servo motor driven variable degree-of-freedom multi-linkage mechanism for gas cutting blanking machine

InactiveCN106607637AReduce weightSmall moment of inertiaGas flame welding apparatusMotor driveDegrees of freedom

The invention provides a dual servo motor driven variable degree-of-freedom multi-linkage mechanism for a gas cutting blanking machine. The multi-linkage mechanism comprises a base 1, a big arm lifting mechanism, a gripper linkage pitching mechanism, a gripper 27, a cutting gun 28, a servo-driving device, a first locking device 5 and a second locking device 12. The big arm lifting mechanism comprises a big arm 8, a fourth connecting rod 3 and a fifth connecting rod 6; the gripper linkage pitching mechanism comprises a driving rod 16, a first connecting rod 18, a second connecting rod 21 and a third connecting rod 11; the first locking device 5 and the second locking device 12 are respectively mounted on an eleventh rotating pair 4 and an eighth rotating pair 7, so as to perform timely locking according to different working conditions of a gas cutting blanking mechanism; the servo-driving device comprises a first servo motor which is connected to the driving rod 16 to drive the same to rotate; and the first locking device 5 and the second locking device 12 perform locking in an electromagnetic manner. According to the multi-linkage mechanism, a two-degree-of-freedom gas cutting blanking operation can be realized by using only one driving rod, so that the number of motors is reduced and the cost of the gas cutting blanking mechanism is reduced.

Owner:GUANGXI UNIV

Multi-degree-of-freedom connecting rod mechanism wood grasping machine driven by servo motors

InactiveCN106759567AImprove stabilityImprove reliabilityMechanical machines/dredgersChain structureElectric machinery

The invention provides a multi-degree-of-freedom connecting rod mechanism wood grasping machine driven by servo motors. The multi-degree-of-freedom connecting rod mechanism wood grasping machine comprises a base, a large arm hoisting mechanism, a wrist connecting rod pitching mechanism, a wrist, a gripper and a servo driving device, wherein the large arm hoisting mechanism is composed of a second driving rod 19, a third connecting rod 3 and a large arm 5; one end of the second driving rod 19 is connected with the base 1 through a second rotary pair 17 and the other end of the second driving rod 19 is connected with the large arm 5 through a third rotary pair 18; one end of the third connecting rod 3 is connected with the base 1 through a tenth rotary pair 2 and the other end of the third connecting rod 3 is connected with the large arm 5 through a first rotary pair 4; the servo driving device comprises a first servo motor and a second servo motor which are connected with a first driving rod 15 and a second driving rod 19 respectively to drive the first driving rod and the second driving rod to rotate, so that large arm hoisting, pitching of a wrist connecting rod 7 and the wrist 27 and other movements are jointly finished and wood grasping work of the gripper 28 is realized. According to the multi-degree-of-freedom connecting rod mechanism wood grasping machine provided by the invention, the disadvantage that a driving motor of an open-chain structure needs to be mounted at a joint position is overcome, and the stability and reliability of movement of the arm are improved.

Owner:GUANGXI UNIV

Servo driving connection rod type variable degree-of-freedom connection rod mechanism for oxygen-acetylene cutting machine

InactiveCN106607872AReduce weightSmall moment of inertiaProgramme-controlled manipulatorGas flame welding apparatusElectric machineryDegrees of freedom

A servo driving connection rod type variable degree-of-freedom connection rod mechanism for a oxygen-acetylene cutting machine is characterized by comprising a base 1, a large arm lifting mechanism, a gripper connection rod luffing mechanism, a gripper 31, a cutting gun 32, a servo driving device, a first locking device 9 and a second locking device 19. The large arm lifting mechanism comprises a large arm 14 and a lifting mechanism. The large arm 14 is connected to the base 1 through a seventh rotary pair 13. The servo driving device comprises a first servo motor connected with a driving rod 3 so as to drive the driving rod 3 to rotate. The first locking device 9 and the second locking device 19 are locked in an electromagnetism mode. According to the servo driving connection rod type variable degree-of-freedom connection rod mechanism, a novel connection rod transmission mechanism is adopted for replacing traditional hydraulic transmission, the defects that a hydraulic oxygen-acetylene cutting machine hydraulic system is complex, liable to oil leakage and high in machining precision requirement, due to the fact that the locking devices are adopted on rotary pairs, two degree-of-freedom oxygen-acetylene cutting operation can be conducted through the one driving rod, and the motor usage quantity is reduced.

Owner:GUANGXI UNIV

Method for grabbing and loading industrial wastes by variable-degree-of-freedom connecting rod mechanism comprising rotating pair locking device

InactiveCN106695821ALess freedomReduce weightProgramme-controlled manipulatorArmsDegrees of freedomEngineering

A method for grabbing and loading industrial wastes by a variable-degree-of-freedom connecting rod mechanism comprising a rotating pair locking device is characterized in that the variable-degree-of-freedom connecting rod mechanism comprising the rotating pair locking device comprises a base 1, a big arm retractable mechanism, a lower arm lifting mechanism, a wrist connecting rod maintaining mechanism, a servo driving device, a first locking device 25 and a second locking device 26, wherein the big arm retractable mechanism consists of a fourth connecting rod 5, a first driving rod 3, a second driving rod 20 and a first connecting rod 22; the maintaining mechanism consists of a second connecting rod 17, a maintaining connecting rod 18 and a big arm 8; the first locking device 25 is mounted on a second rotating pair 4; the second locking device 26 is mounted on a tenth rotating pair 16; and the servo driving device comprises a first servo motor and a second servo motor which are connected with the first driving rod 3 and the second driving rod 20 so as to drive the first driving rod 3 and the second driving rod 20 to rotate. The variable-degree-of-freedom connecting rod transmission mechanism replaces traditional hydraulic transmission, and therefore, the shortcoming that a hydraulic system is complicated and leaks oil easily is overcome.

Owner:GUANGXI UNIV

Variable-degree-of-freedom link mechanism mechanical arm for carrying operation

InactiveCN106607867ALess freedomReduce weightProgramme-controlled manipulatorArmsElectric machineryDegrees of freedom

The invention discloses a variable-degree-of-freedom link mechanism mechanical arm for carrying operation. The variable-degree-of-freedom link mechanism mechanical arm comprises a base 1, a large arm lifting mechanism, a wrist link pitching mechanism, a wrist 27, a vacuum chuck 28, a servo driving device, a first locking device 5 and a second locking device 12; the large arm lifting mechanism comprises a large arm 8, a fourth link 3 and a fifth link 6; the wrist link pitching mechanism comprises a driving rod 16, a first link 18, a second link 21 and a third link 11; the first locking device 5 and the second locking device 12 are respectively arranged on an eleventh rotation pair 4 and an eighth rotation pair 7, and can carried out timing locking according to different working conditions of the variable-degree-of-freedom link mechanism mechanical arm; the servo driving device comprises a first servo motor; the first servo motor is connected with the driving rod 16 and drives the driving rod 16 to rotate; and the first locking device 5 and the second locking device 12 adopt an electromagnetic mode for locking. Two-degree-of-freedom carrying operation can be realized simply by using one driving rod, the use quantity of motors is reduced, and the construction cost of the variable-degree-of-freedom link mechanism mechanical arm is reduced.

Owner:GUANGXI UNIV

Method for grabbing industrial waste by virtue of servo motor-driven variable-degree-of-freedom connecting bar mechanism

InactiveCN106737832ALess freedomReduce weightProgramme-controlled manipulatorGripping headsMotor driveChain structure

The invention relates to a method for grabbing industrial waste by virtue of a servo motor-driven variable-degree-of-freedom connecting bar mechanism. The method is characterized in that the servo motor-driven variable-degree-of-freedom connecting bar mechanism comprises a base (1), a big arm (17), a wrist connecting bar pitching mechanism, a first locking device (8) and a second locking device (16), wherein the wrist connecting bar pitching mechanism comprises a wrist connecting bar and a pitching mechanism, the wrist connecting bar is connected to the big arm (17) through a ninth rotating pair (19) and a tenth rotating pair (20) which are coaxially arranged, the pitching mechanism comprises a driving component (3), a first connecting rod (5), a second connecting rod (10) and a third connecting rod (9), and the first locking device (8) and the second locking device (16) are respectively mounted on a fourth rotating pair (7) and a seventh rotating pair (15) and are used for locking in proper time according to different work stations of the mechanism; and the first connecting rod (5), a second connecting rod (10) are used for locking in an electromagnetic manner. By virtue of the method, the disadvantage that driving motors being of an open chain structure need to be mounted at joint positions is overcome, and the number of adopted controllable driving motors is smaller than the degree of freedom of the connecting rod mechanism.

Owner:GUANGXI UNIV

Servo driving connection rod type variable degree-of-movement mechanism for oxygen-acetylene cutting machine

InactiveCN106607871ALess freedomReduce weightProgramme-controlled manipulatorGas flame welding apparatusThree degrees of freedomEngineering

The invention discloses a servo driving connection rod type variable degree-of-movement mechanism for an oxygen-acetylene cutting machine. The servo driving connection rod type variable degree-of-movement mechanism comprises a base, a large arm telescopic mechanism, a lifting mechanism, a gripper connection rod luffing mechanism and gripper, a cutting gun, a servo driving device and two locking devices. The large arm telescopic mechanism comprises a first connection rod, a second connection rod and a third connection rod. One end of the first connection rod is connected with the base through a first rotary pair. The other end of the first connection rod is connected with one end of the third connection rod through a third rotary pair. The other end of the third connection rod is connected with the second connection rod through a fourth rotary pair. One end of the second connection rod is connected with the base through a second rotary pair. The other end of the second connection rod is connected with a large arm through a fifth rotary pair. The locking devices are installed on the rotary pairs. According to the servo driving connection rod type variable degree-of-movement mechanism, a connection rod transmission mechanism is adopted for replacing traditional hydraulic transmission, the defects that a hydraulic oxygen-acetylene cutting machine hydraulic system is complex and is liable to oil leakage can be overcome, and due to the fact that the locking devices are adopted on the rotary pairs, three-degree-of-freedom oxygen-acetylene cutting operation can be achieved through two driving rods.

Owner:GUANGXI UNIV

Variable-activity connecting rod mechanism driven by servo motor

The invention discloses a variable-activity connecting rod mechanism driven by a servo motor. The variable-activity connecting rod mechanism comprises a base 1, a large arm lifting mechanism, a wrist connecting rod pitching mechanism, a servo drive device, a first locking device 5 and a second locking device 22. The large arm lifting mechanism comprises a large arm 20, a first connecting rod 3 and a second connecting rod 6. The wrist connecting rod pitching mechanism comprises a drive rod 17, a third connecting rod 15, a connecting piece 13 and a fourth connecting rod 11. The first locking device 5 and the second locking device 22 are installed on a second rotation pair 4 and a fifth rotation pair 7 correspondingly. The servo drive device comprises the first servo motor which is connected with the drive rod 17 to drive the drive rod 17 to rotate. The first locking device 5 and the second locking device 22 conduct locking in an electromagnetic manner. According to the variable-activity connecting rod mechanism, work of two freedom degrees can be achieved simply through one drive rod, the use number of motors is reduced, and the manufacturing cost of the mechanism is reduced.

Owner:GUANGXI UNIV

Industrial waste grabbing and loading method with variable-range-of-motion connecting rod mechanism driven by servo motor

InactiveCN106607866ALess freedomReduce weightProgramme-controlled manipulatorLoading/unloadingThree degrees of freedomRange of motion

The invention discloses an industrial waste grabbing and loading method with a variable-range-of-motion connecting rod mechanism driven by a servo motor. The industrial waste grabbing and loading method is characterized in that the variable-range-of-motion connecting rod mechanism driven by the servo motor comprises a base, a large arm telescoping mechanism, a lifting mechanism, a wrist connecting rod pitching mechanism, a wrist, a paw, a servo driving device and two locking devices, wherein the large arm telescoping mechanism comprises a first connecting rod, a second connecting rod and a third connecting rod, one end of the first connecting rod is connected with the base by virtue of a first revolving pair, the other end of the first connecting rod is connected with one end of the third connecting rod by virtue of a third revolving pair, the other end of the third connecting rod is connected with the second connecting rod by virtue of a fourth revolving pair, one end of the second connecting rod is connected with the base by virtue of a second revolving pair, the other end of the second connecting rod is connected with a large arm by virtue of a fifth revolving pair, and the locking devices are installed on the revolving pairs. According to the industrial waste grabbing and loading method, the connecting rod transmission mechanism is used for replacing traditional hydraulic transmission, so that the defects of complex hydraulic system, easiness in oil leakage and the like of a hydraulic industrial waste grabbing and loading machine can be solved; the locking devices are installed on the revolving pairs, so that the three-degree-of-freedom operation can be realized only by utilizing two driving rods.

Owner:GUANGXI UNIV

Servo drive rod variable-degree-of-freedom mechanical arm for carrying operation

InactiveCN108147106AImprove smoothness and reliabilityNo cumulative errorConveyor partsElectric machineryTwo degrees of freedom

The invention discloses a servo drive rod variable-degree-of-freedom mechanical arm for carrying operation. The mechanical arm is characterized by comprising a base 1, a large arm lifting mechanism, awrist connecting rod pitching mechanism, a wrist 31, a vacuum sucker 32, a servo driving device, a first locking device 9 and a second locking device 19; the large arm lifting mechanism consists of alarge arm 14 and a lifting mechanism; the large arm 14 is connected to the base 1 through a seventh rotating pair 13; the servo driving device comprises a first servo motor which is connected with adriving rod 3 and drives the driving rod 3 to rotate; and the first locking device 9 and the second locking device 19 are locked by adopting an electromagnetic mode. A novel connecting rod transmission mechanism is adopted to replace traditional hydraulic transmission; the defects of complicated hydraulic system, easy oil leakage, high machining precision requirement and the like in a hydraulic carrying operation mechanical arm are solved; and as the locking devices are adopted on a rotating pair, one driving rod can be used for realizing two-degree-of-freedom carrying operation, and the motoruse number is reduced.

Owner:GUANGXI UNIV

Method of carrying out industrial waste seizing and loading operation by adopting dual-servo motor driven variable-degree-of-freedom multi-link mechanism

The invention discloses a method of carrying out industrial waste seizing and loading operation by adopting a dual-servo motor driven variable-degree-of-freedom multi-link mechanism. The method is characterized in that the dual-servo motor driven variable-degree-of-freedom multi-link mechanism comprises a base 1, a large arm lifting mechanism, a wrist link pitching mechanism, a servo driving device, a first locking device 5 and a second locking device 12; the large arm lifting mechanism comprises a large arm 8, a fourth link 3 and a fifth link 6; the wrist link pitching mechanism comprises a driving rod 16, a first link 18, a second link 21 and a third link 11; the first locking device 5 and the second locking device 12 are respectively arranged on an eleventh rotation pair 4 and an eighth rotation pair 7, and can carry out timing locking according to different working conditions; the servo driving device comprises a first servo motor; the first servo motor is connected with the driving rod 16 and drives the driving rod 16 to rotate; and the first locking device 5 and the second locking device 12 adopt an electromagnetic mode for locking. According to the method, two-degree-of-freedom operation can be realized simply by using one driving rod, the use quantity of motors is reduced, and the construction cost is reduced.

Owner:GUANGXI UNIV

Popular searches

Reduce volume Low cost Improve controllability Overcomes the disadvantages of being installed in a joint position Overcoming demands Overcoming structural complexity Overcoming oil spills Overcoming reliability Overcome efficiency Overcomes the disadvantage of needing to be installed in a joint position

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com