Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Holding brake function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

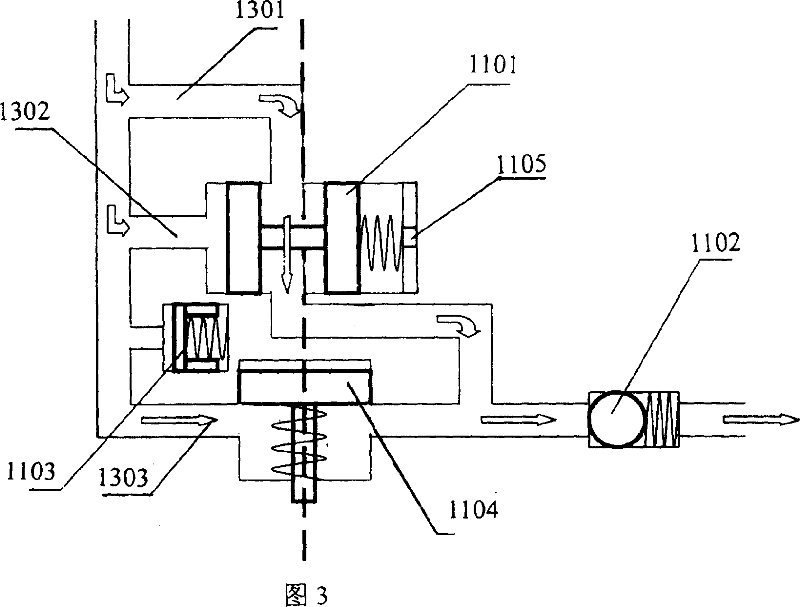

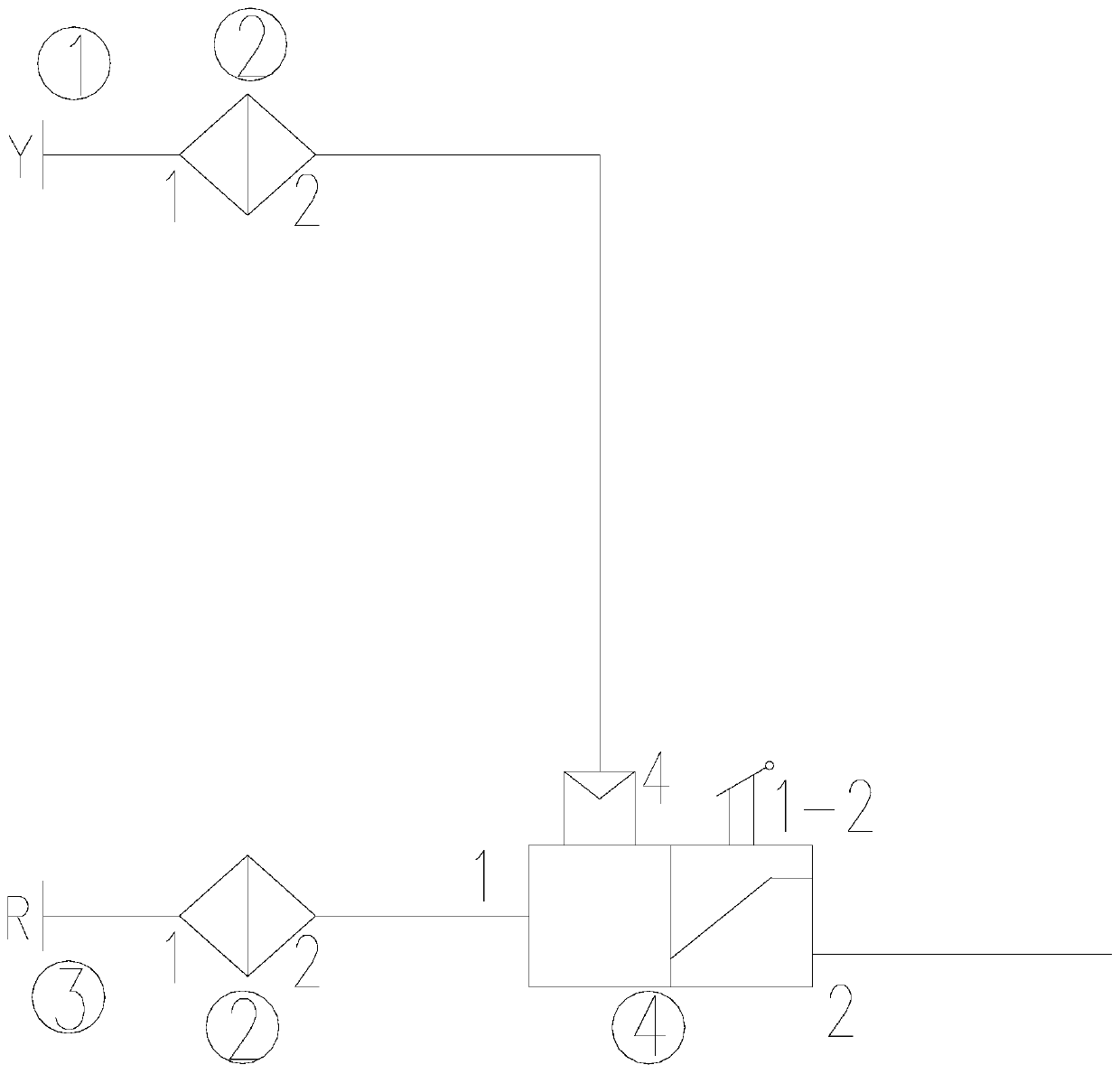

Air stand-by brake system and brake method

ActiveCN103434504AHolding brake functionReduce the impact of orderBraking action transmissionAerodynamic brakesRelay valveControl system

The invention discloses an air stand-by brake system and brake method. The air stand-by brake system comprises a brake controller, an equalizing reservoir, a relay valve, an input valve and a throttle valve; the air stand-by brake system is connected with an original train pipe of a locomotive through the input valve, and connected with an original main blast line of the locomotive through the throttle valve; if a main brake control system is power-off, the input valve is used for being opened to a switch-on position, so that an air channel is communicated; the brake controller is used for controlling the pressurization and depressurization of the equalizing reservoir; the equalizing reservoir is used for taking the pressure of the equalizing reservoir as the pilot pressure of the relay valve; and the relay valve is used for controlling the pressure change of the train pipe according to the pressure change of the equalizing reservoir, wherein the pressure of the equalizing reservoir and the pressure of the train pipe are in a synchronous state. According to the embodiment of the invention, the brake function of the locomotive can be ensured, so that the locomotive can continue to run and maintain to a locomotive depot, and then is maintained, in such a way, the locomotive does not stop on a trunk railway for a long tine, thereby reducing the effect on the order of a railway.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

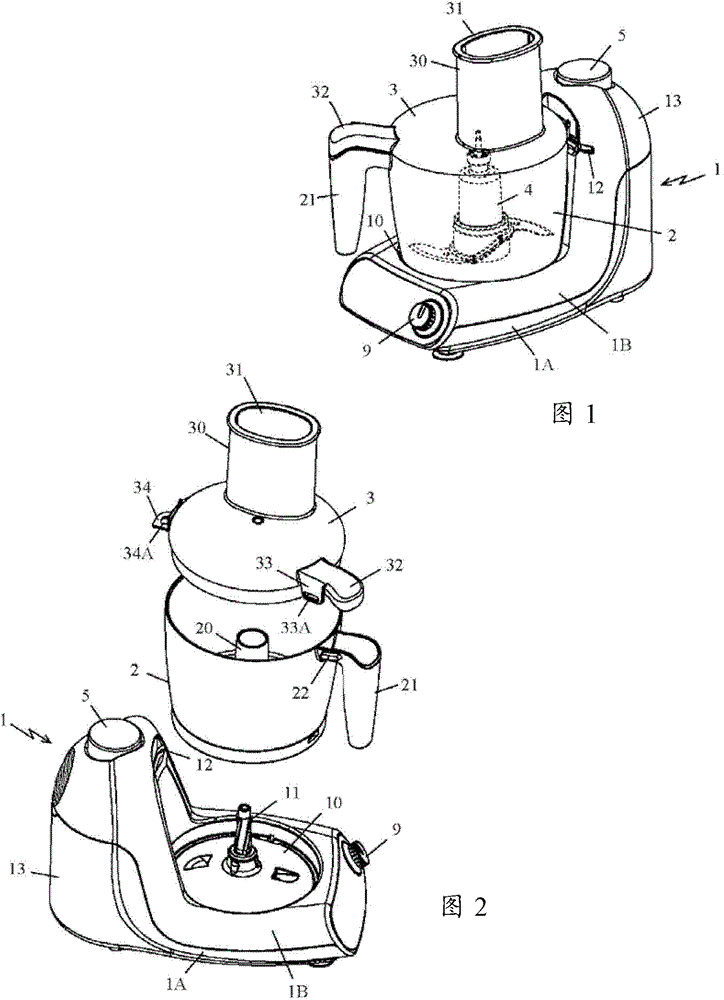

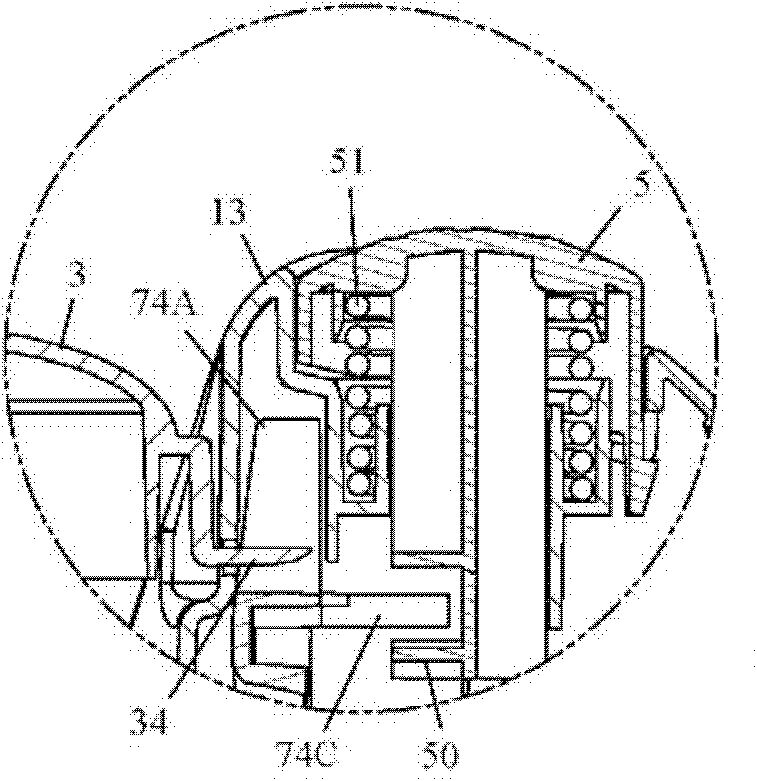

Household cooking appliance comprising a receptacle containing a motor driven cutting tool

The invention relates to a household cooking appliance which includes a receptacle (2). The inside of the receptacle (2) is provided with a cutting tool (4) which is driven by a motor (15). The receptacle (2) is closed by a removable cover (3) comprising a bracket (34) acting on a safety part (7) when the bracket (34) of the cover (3) is turned toward an operating position. The safety part (7) moves between an idle position and an activated position. The safety part (7) is returned to the idle position via a return mechanism (72). When the bracket (34) is on the operating position (34), the safety part (7) is brought t to the activated position. The safety part (7) comprises a metal braking shoe (76) rubbing against a transmission belt (16) rotatingly integrated to the cutting tool (4) when the safety part is in a rest position. The shoe (76) is arranged apart from the belt (16) when the safety part is in an activated position.

Owner:SEB SA

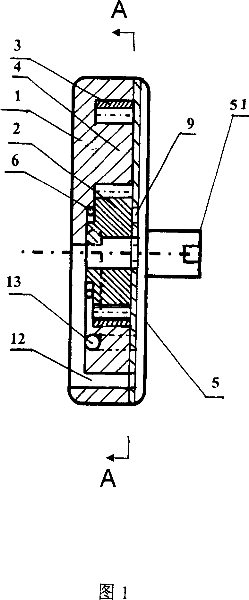

Pump type hydraulic coupler

InactiveCN1786503AHolding brake functionImprove transmission efficiencyRotary clutchesRotary couplingEngineeringHigh pressure

A pump-type hydraulic coupler belongs to a vehicle coupler, in which a pinion is rotating connected in the casing. The pinion inside engaged with a big gear ring. There is a crescent spacer between the pinion and the big gear ring. The back cover of the casing is connected with the casing. One end of connection of the pinion and the casing is connected with a one-way clutch.

Owner:CHANGCHUN JIANBANG AUTOMOBILE PROD

Pump type hydraulic coupler

InactiveCN100337048CHolding brake functionImprove transmission efficiencyRotary clutchesRotary couplingEngineeringHigh pressure

Owner:CHANGCHUN JIANBANG AUTOMOBILE PROD

Air backup braking system and braking method

ActiveCN103434504BHolding brake functionReduce the impact of orderBraking action transmissionAerodynamic brakesRelay valveControl system

The invention discloses an air stand-by brake system and brake method. The air stand-by brake system comprises a brake controller, an equalizing reservoir, a relay valve, an input valve and a throttle valve; the air stand-by brake system is connected with an original train pipe of a locomotive through the input valve, and connected with an original main blast line of the locomotive through the throttle valve; if a main brake control system is power-off, the input valve is used for being opened to a switch-on position, so that an air channel is communicated; the brake controller is used for controlling the pressurization and depressurization of the equalizing reservoir; the equalizing reservoir is used for taking the pressure of the equalizing reservoir as the pilot pressure of the relay valve; and the relay valve is used for controlling the pressure change of the train pipe according to the pressure change of the equalizing reservoir, wherein the pressure of the equalizing reservoir and the pressure of the train pipe are in a synchronous state. According to the embodiment of the invention, the brake function of the locomotive can be ensured, so that the locomotive can continue to run and maintain to a locomotive depot, and then is maintained, in such a way, the locomotive does not stop on a trunk railway for a long tine, thereby reducing the effect on the order of a railway.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

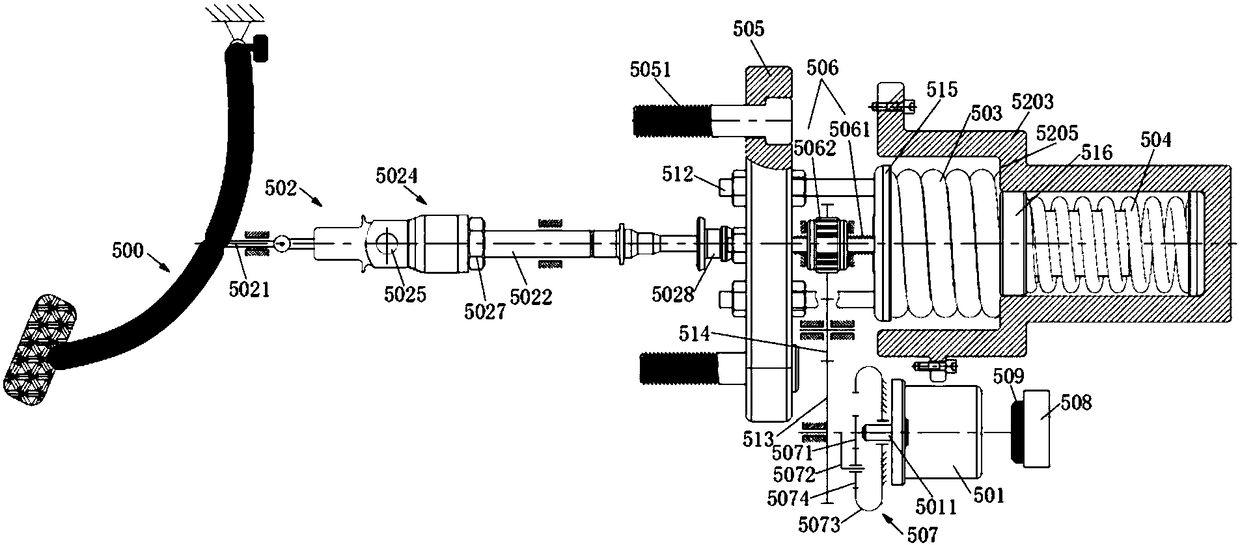

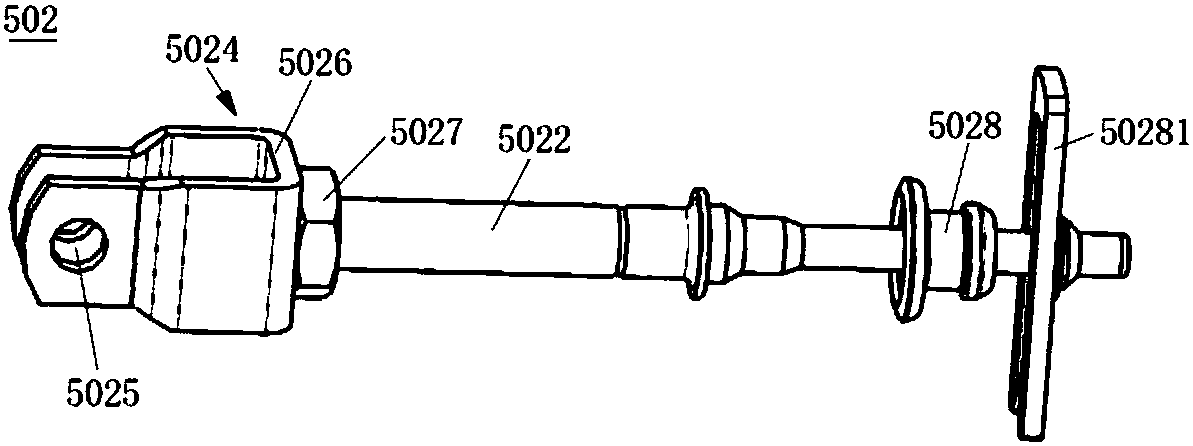

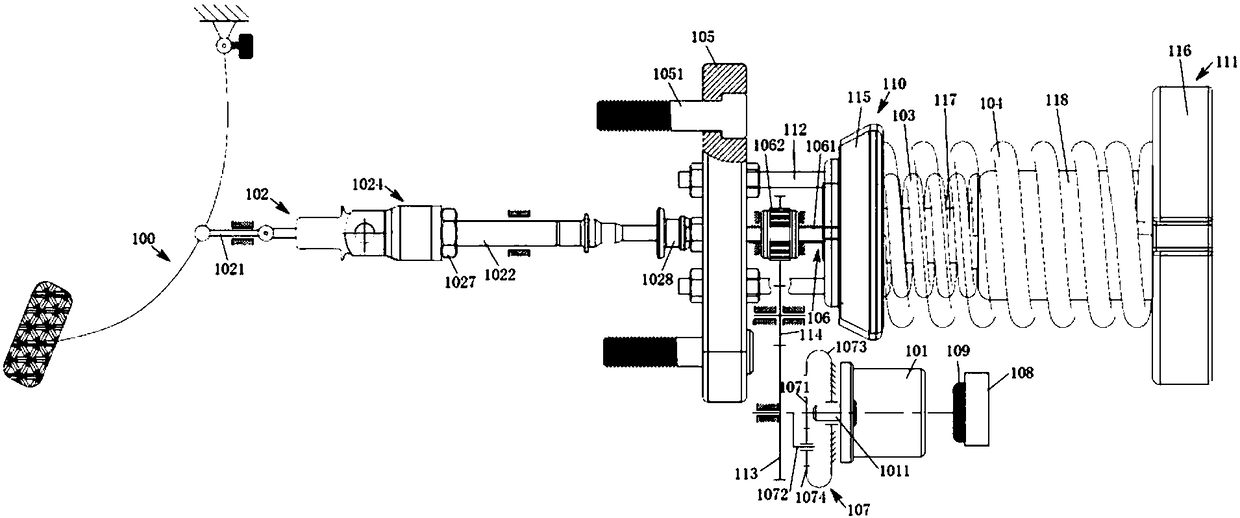

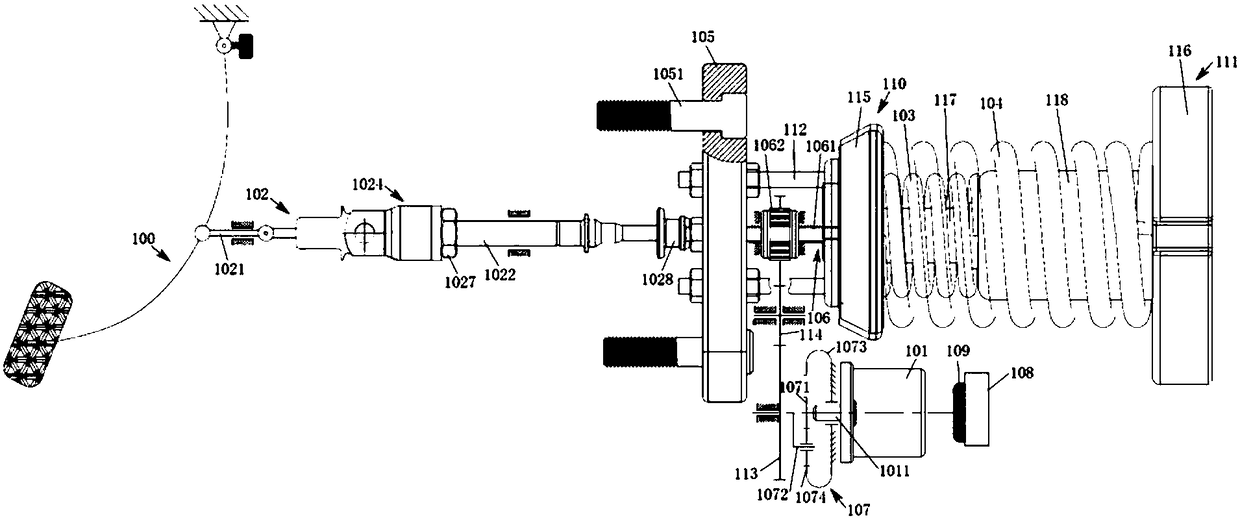

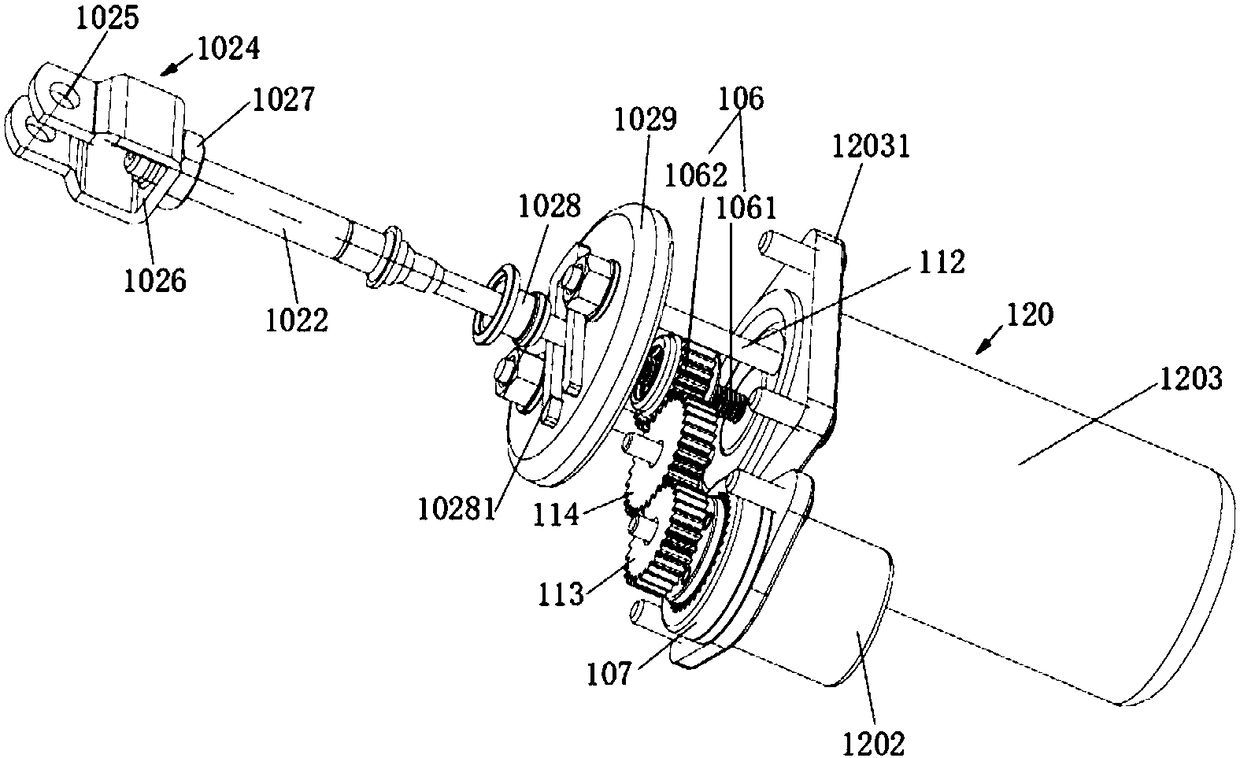

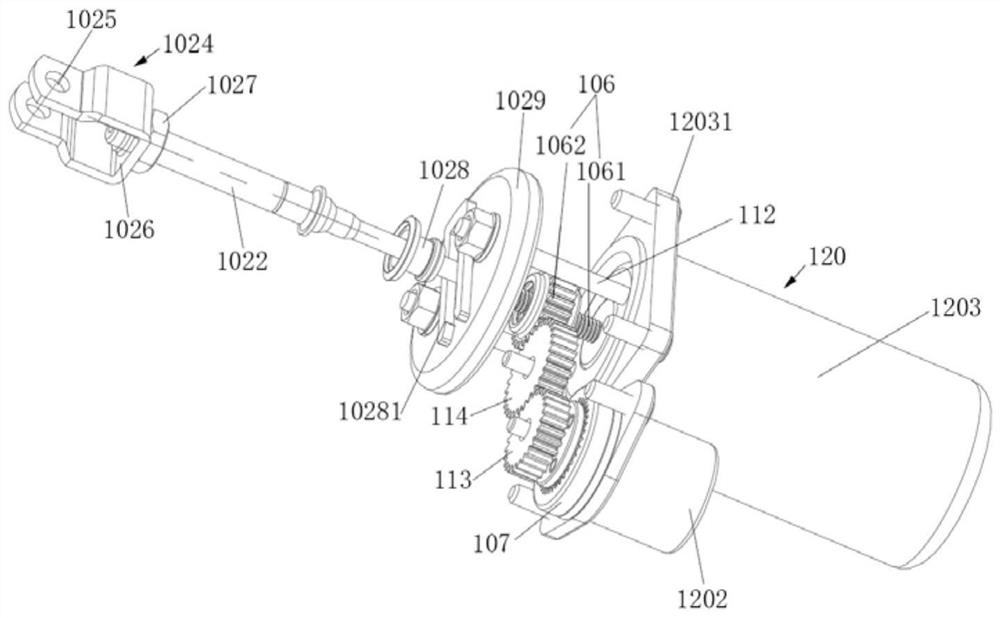

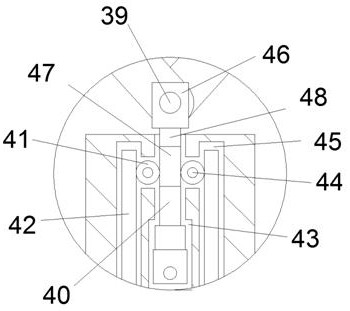

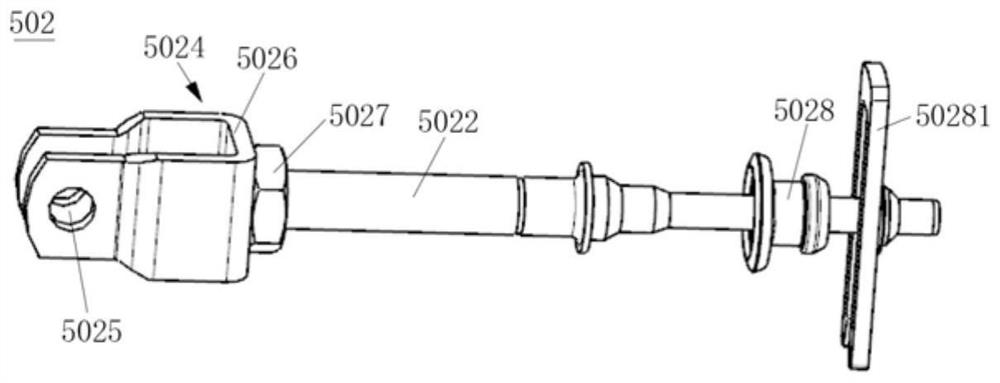

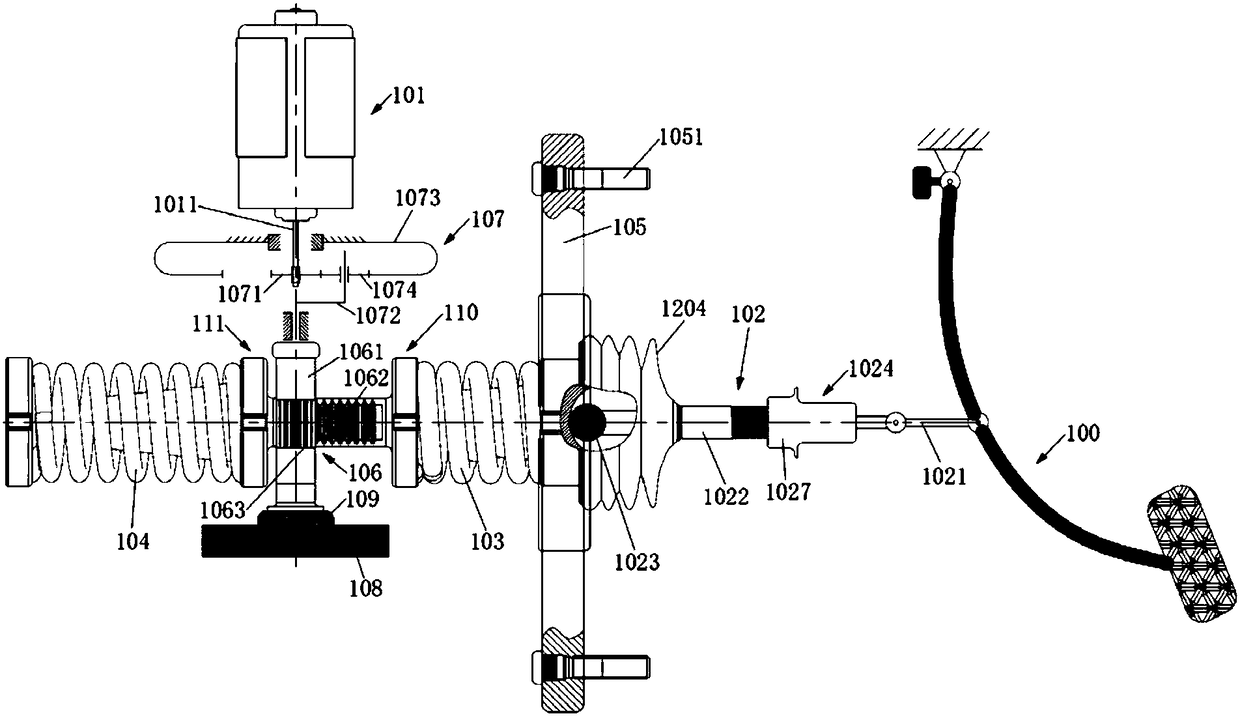

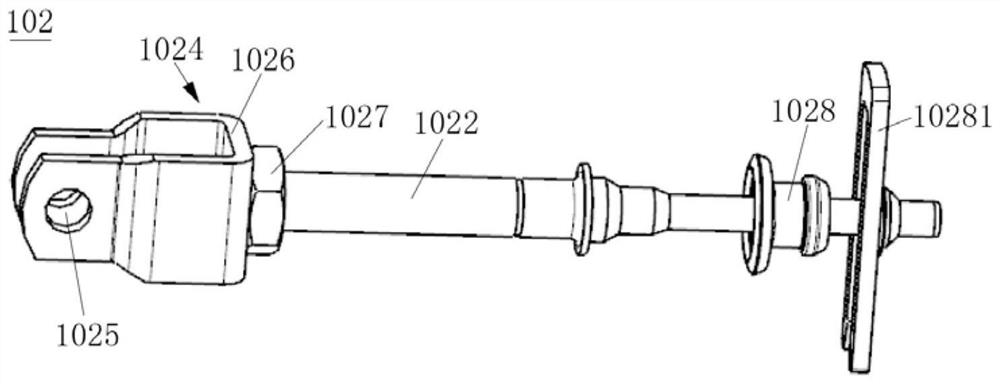

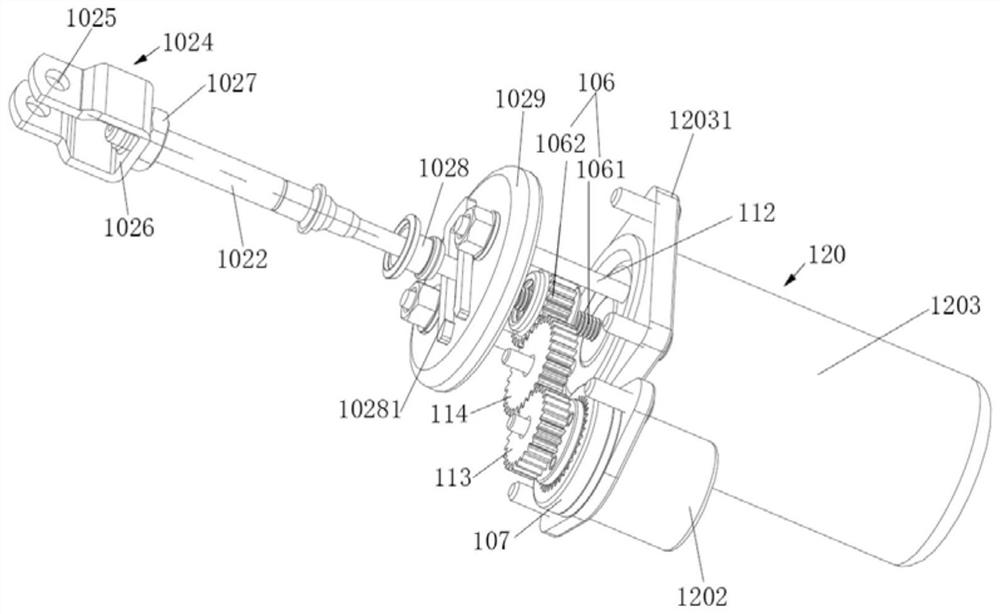

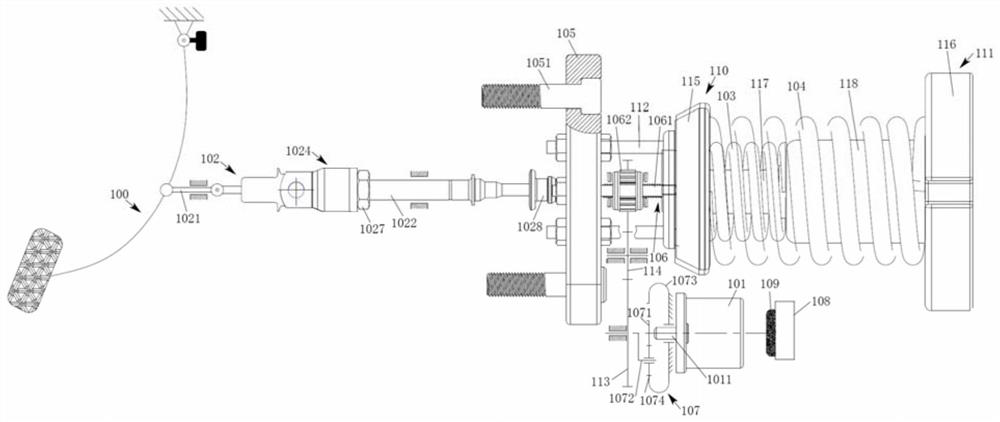

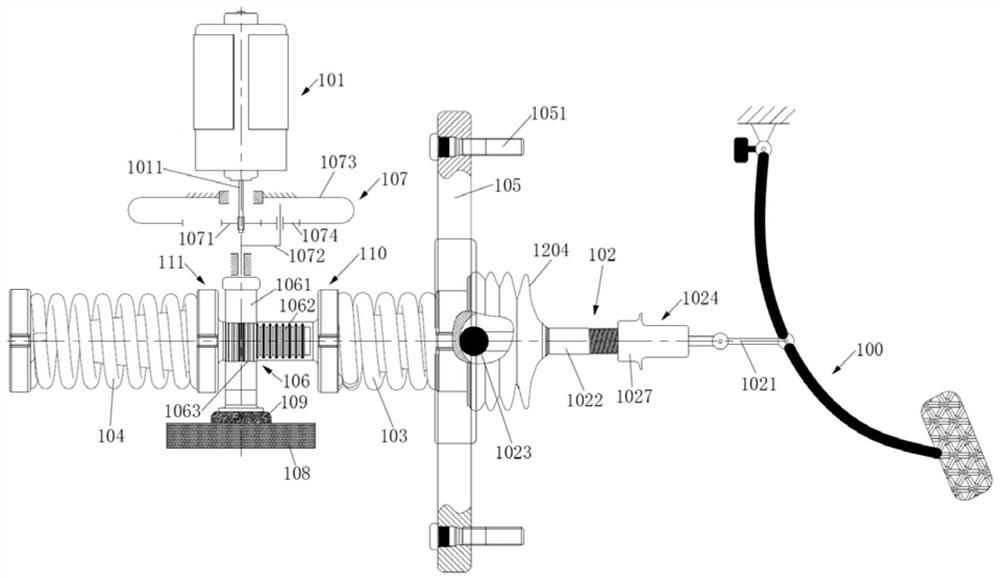

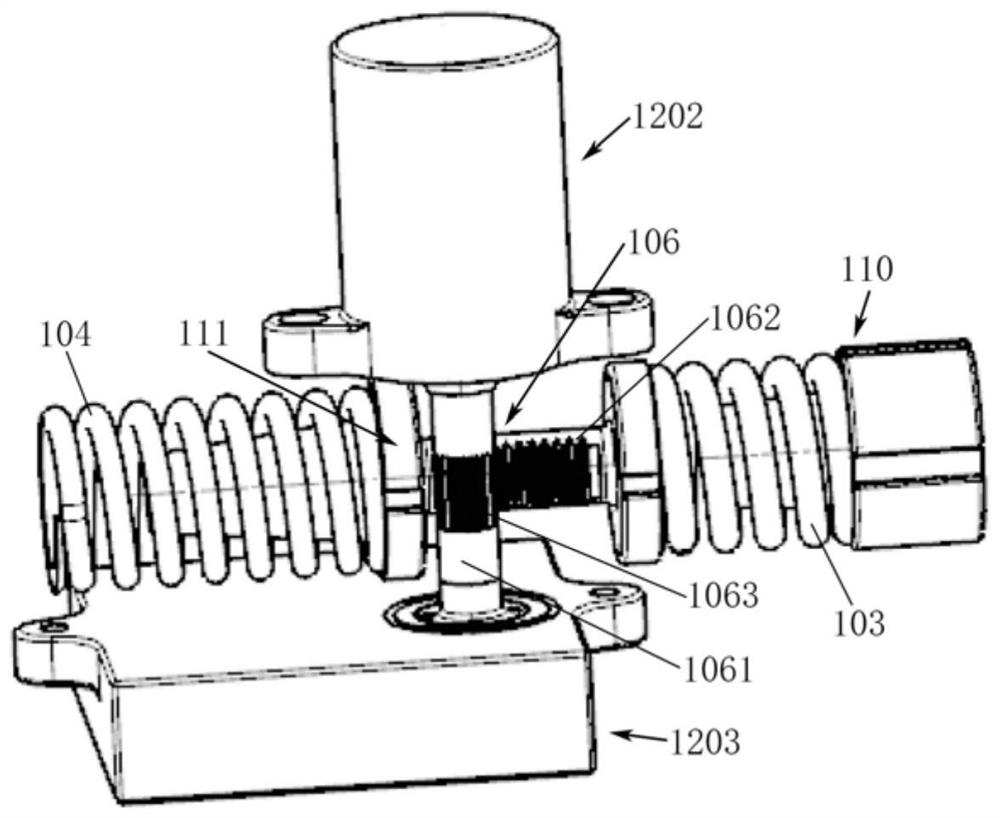

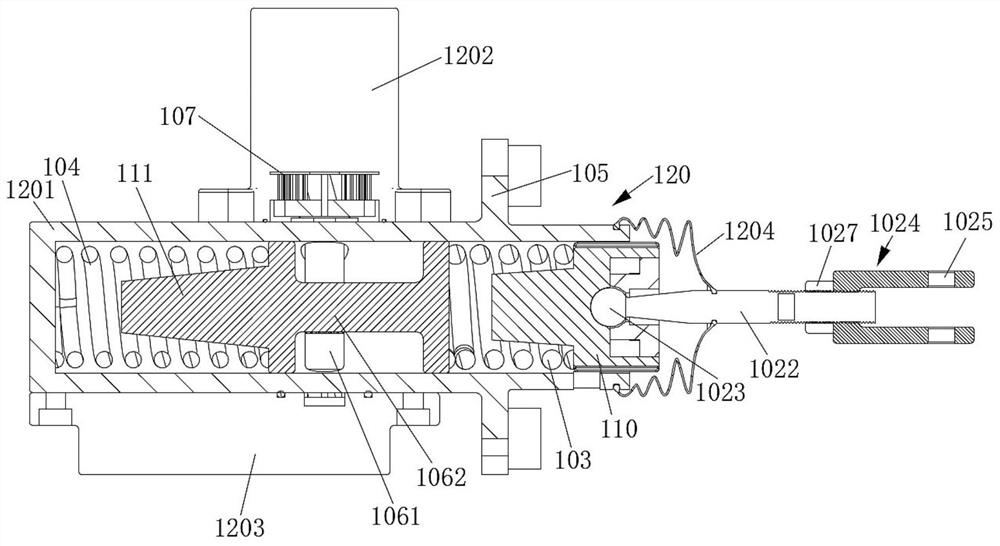

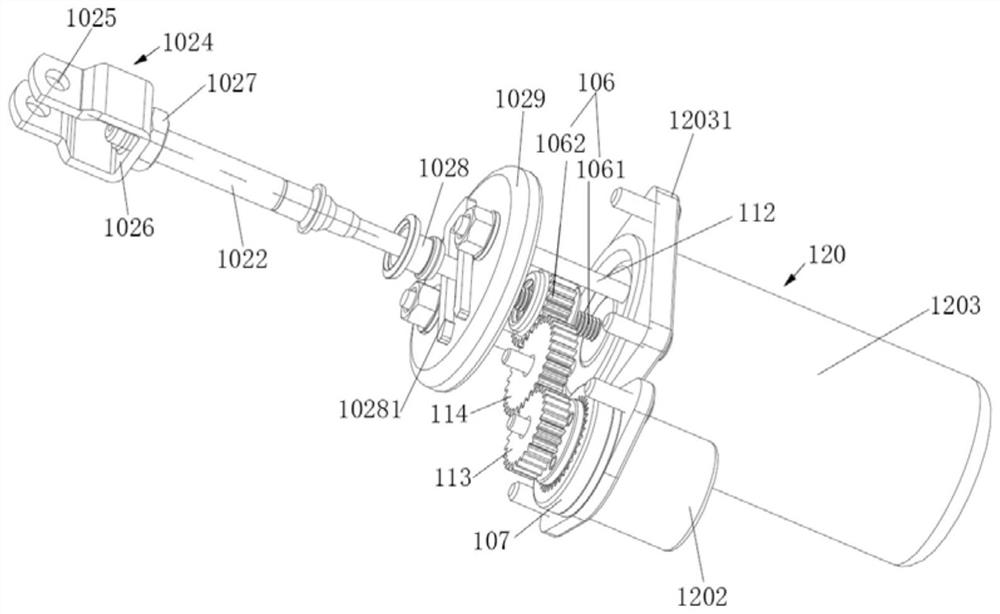

A brake pedal simulator, a vehicle braking system and a vehicle

ActiveCN109204270AReliable braking feelBraking feels accurateFoot actuated initiationsEngineeringOperational stability

A brake pedal simulator, a vehicle braking system and a vehicle are provided. The brake pedal simulator includes a brake pedal, a booster motor, an assembly portion, a first elastic member and a second elastic member arranged at axially spaced intervals on both sides of the assembly portion, a rack and pinion mechanism located between the two second elastic members, and a thrust structure hinged to the brake pedal and capable of sequentially driving the first elastic member and the second elastic member to telescopically retract in the axial direction. The first elastic member provides a pedalpreset force to the brake pedal, the output shaft of the booster motor is capable of cooperating with the second elastic member through the rack-and-pinion mechanism to provide assistance for the driving of the thrust structure, the first elastic member is compressed through the thrust mechanism in a first working state, and the first elastic member and the second elastic member are compressed synchronously through the cooperation of the thrust mechanism and the booster motor in a second working state. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

Lifting straddle-type single-rail device assembling and disassembling trolley and method

PendingCN110216618AImprove work efficiencyIncrease job securityWork benchesMetal-working hand toolsEngineeringProcess requirements

The invention discloses a lifting straddle-type single-rail device assembling and disassembling trolley. The lifting straddle-type single-rail device assembling and disassembling trolley comprises a trolley body, a lifting platform, a platform moving device, a platform locking device and a plurality of trolley body traveling wheels. The trolley body traveling wheels are arranged under the trolleybody and provided with brake devices. The lifting platform is arranged on the trolley body. The platform moving device is arranged between the trolley body and the lifting platform. The platform locking device is arranged between the trolley body and the lifting platform. By adoption of the lifting straddle-type single-rail device assembling and disassembling trolley, the process requirement for maintenance of full-automatic-drive straddle-type single-rail vehicle devices can be met according to the characteristics of straddle-type single rails and the maintenance requirements, inconvenience and difficulties during maintenance of the straddle-type single-rail vehicle device, and the maintenance efficiency and safety of the devices are improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A brake pedal simulator, a vehicle braking system and a vehicle

ActiveCN109204269AQuick responseFast braking feelFoot actuated initiationsOperational stabilityRack and pinion

A brake pedal simulator, a vehicle braking system and a vehicle are provided. The brake pedal simulator includes a brake pedal, a booster motor, an assembly part for fitting to a vehicle body, a firstelastic member and a second elastic member axially disposed on one side of the fitting portion and at least partially overlapping with each other in the axial direction, and a thrust structure hingedto the brake pedal and cooperating with one end of the overlapping portion of the first elastic member and the second elastic member to be capable of driving the first elastic member and the second elastic member while telescoping in the axial direction, The first elastic member and the second elastic member cooperate to provide a pedal preset force to the brake pedal, and the output shaft of thebooster motor cooperates with one end of the overlapping portion of the first elastic member and the second elastic member through a rack-and-pinion mechanism so as to be able to provide a boosting force to the thrust structure. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

A brake pedal simulator, a vehicle braking system and a vehicle

ActiveCN109204263AReliable braking feelBraking feels accurateFoot actuated initiationsOperational stabilityRack and pinion

A brake pedal simulator, a vehicle braking system and a vehicle are provided. The brake pedal simulator includes a brake pedal, a booster motor, an assembly portion, a first elastic member and a second elastic member arranged at axially spaced intervals on one side of the assembly portion, a rack and pinion mechanism positioned between the two elastic members, a thrust structure hinged to the brake pedal and capable of sequentially driving the first elastic member and the second elastic member to telescopically retract in the axial direction. The first elastic member provides a pedal preset force to the brake pedal, the output shaft of the booster motor is capable of cooperating with the second elastic member through the rack-and-pinion mechanism to provide assistance for the driving of the thrust structure, the first elastic member is compressed through the thrust mechanism in a first working state, and the first elastic member and the second elastic member are compressed synchronously through the cooperation of the thrust structure and the booster motor in a second working state. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force,and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

A brake pedal simulator, a vehicle braking system and a vehicle

ActiveCN109204268AReliable braking feelBraking feels accurateFoot actuated initiationsOperational stabilityVehicle brake

A brake pedal simulator, a vehicle braking system and a vehicle are provided. The brake pedal simulator includes a brake pedal, a booster motor, an assembly portion, a first elastic member and a second elastic member disposed on one side of the assembly portion in the axial direction and partially overlapping with each other in the axial direction, and a thrust structure hinged to the brake pedaland cooperating with the first elastic member to sequentially drive the first elastic member and the second elastic member to telescopically retract in the axial direction. The first elastic member provides a pedal preset force to the brake pedal, the output shaft of the booster motor is cooperated with the first elastic member through a screw mechanism to be able to provide power to the thrust structure, the first elastic member is compressed through the thrust mechanism in a first working state, and the first elastic member and the second elastic member are compressed synchronously through the cooperation of the thrust mechanism and the booster motor in a second working state. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

Wind driven generator braking equipment

ActiveCN109869272AHolding brake functionShorten speedWind motor controlMachines/enginesWind drivenScrew thread

The invention discloses wind driven generator braking equipment. The equipment comprises a drum brake and a drum brake cavity formed in the drum brake. A body is arranged in the drum brake cavity, andinternally provided with a braking trigger cavity. A center threaded rod extending front and back is arranged in the braking trigger cavity and connected with a push block in a screw thread fit mode.The push block is connected with a lifting block in an abutting mode. The lifting block is connected with a lifting rod in a stationary fit mode. A gear and rack engaging cavity is formed above the braking trigger cavity. The invention aims at designing a device capable of performing braking on a wind driven generator when the rotating speed of the wind driven generator reaches a certain value soas to reduce the speed of the wind driven generator device.

Owner:青岛百恒新能源技术有限公司

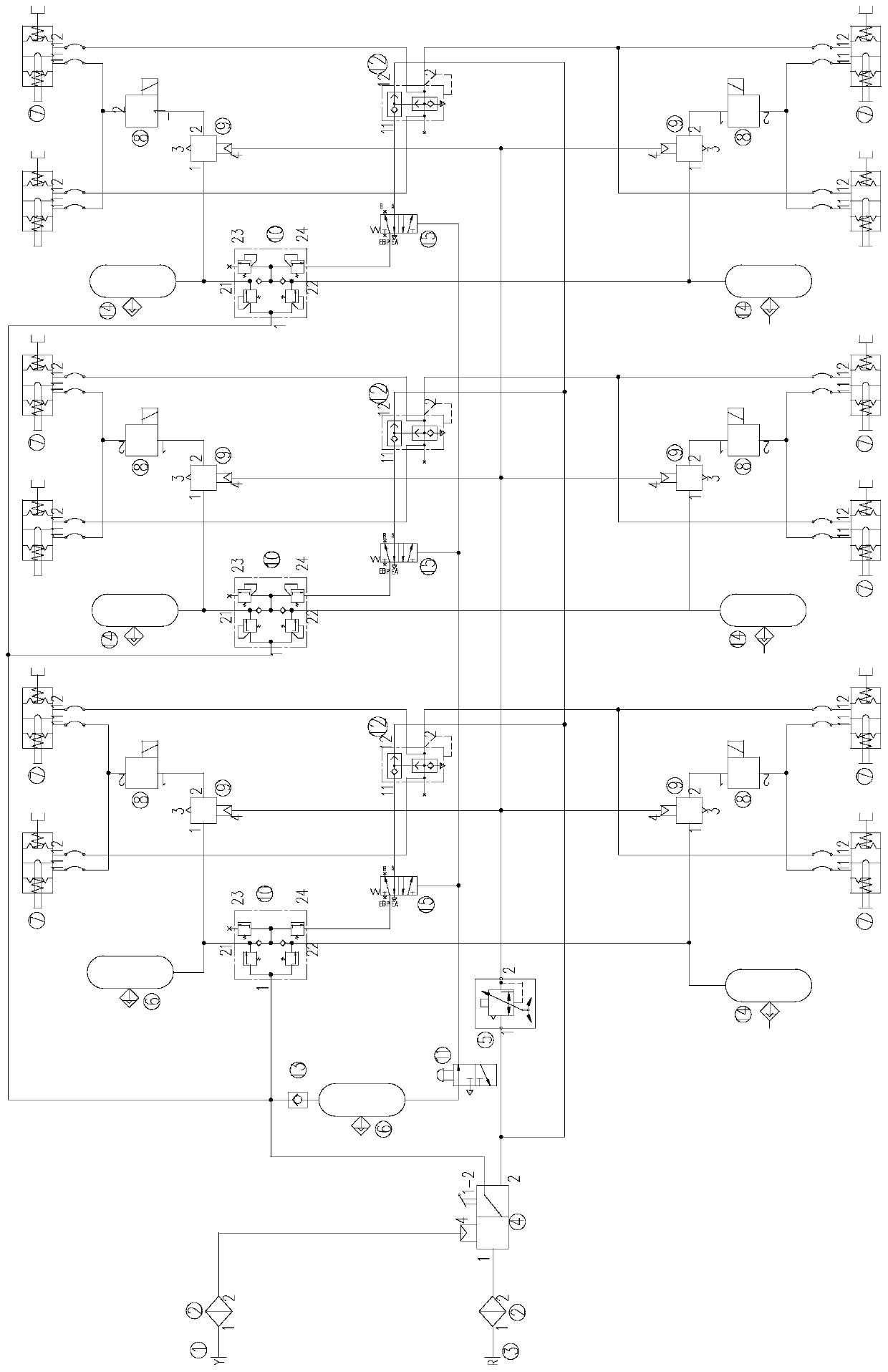

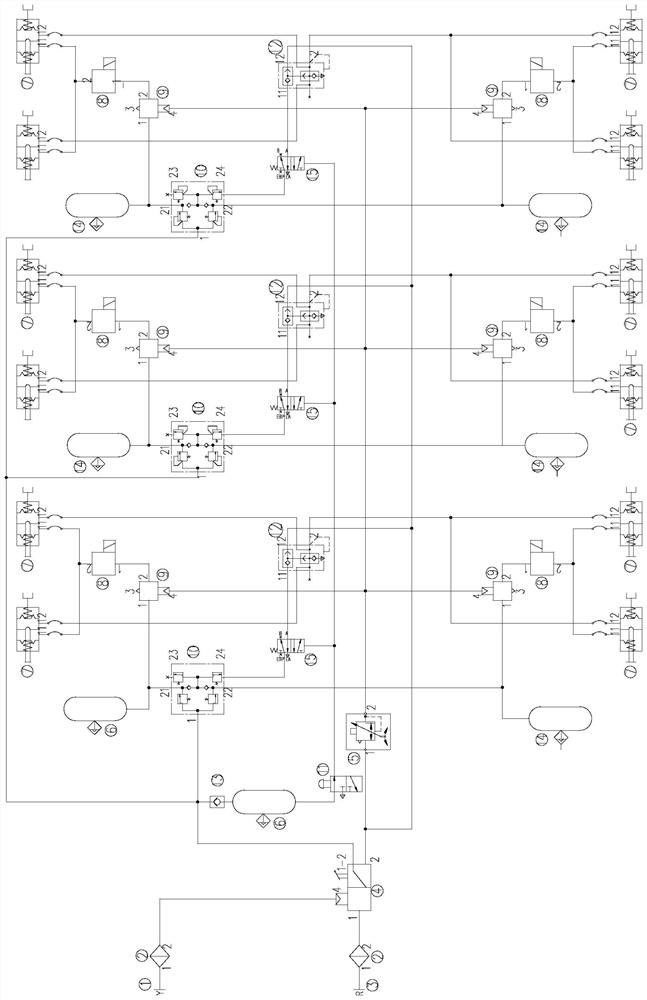

Grouped multi-axle trailer braking system

ActiveCN110962821AReduce wearHolding brake functionBraking action transmissionBrake safety systemsControl theorySelf adaptive

The invention discloses a grouped multi-axle trailer braking system. By means of the characteristics of a four-loop protection valve, the multi-axle trailer braking system is divided into a pluralityof groups of independent two-axle braking systems by using the four-loop protection valve; under the condition that the brake pipeline of any independent group is damaged, only the braking system of the group is influenced and other groups of braking system functions can be still ensured; besides, a parking release control gas circuit is uniformly controlled by using a unique manual parking valve;the manual parking is still controlled only by the unique manual parking valve; an independent parking release air cylinder is also adopted; when an air source fails or other air cylinders leak air and fail, it is guaranteed that the function of relieving parking braking at least once is achieved; the ABS function is further achieved, the braking function has high reliability and stability, tireabrasion is reduced through the self-adaptive capacity of different suspension loads and braking force, and the safety in the driving process is improved.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

A brake pedal simulator, a vehicle braking system and a vehicle

ActiveCN109204272AReliable braking feelBraking feels quickFoot actuated initiationsEngineeringOperational stability

A brake pedal simulator, a vehicle braking system and a vehicle are provided. The brake pedal simulator includes a brake pedal, a booster motor, an assembly portion, a first elastic member and a second elastic member disposed on one side of the assembly portion in the axial direction and partially overlapping with each other in the axial direction, and a thrust structure hinged to the brake pedaland cooperating with the first elastic member to sequentially drive the first elastic member and the second elastic member to telescopically retract in the axial direction. The elastic resilient member provides a pedal preset force to the brake pedal, The output shaft of the booster motor is cooperated with the first elastic member through a rack and pinion mechanism so as to be able to provide assistance to the thrust structure, the first elastic member is compressed through the thrust mechanism in a first working state, and the first elastic member and the second elastic member are compressed synchronously through the cooperation of the thrust structure and the booster motor in a second working state. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

Brake pedal simulator, car braking system and vehicle

ActiveCN109204267BQuick responseFast braking feelFoot actuated initiationsElectric machineryControl theory

A brake pedal simulator, a vehicle braking system and a vehicle are provided, wherein the brake pedal simulator includes a brake pedal, a booster motor, an assembly part for fitting to a vehicle body,a first elastic member and a second elastic member disposed axially on one side of the fitting portion and at least partially overlapping with each other in the axial direction, and a thrust structure hinged to the brake pedal and cooperating with one end of the overlapping portion of the first elastic member and the second elastic member to be capable of driving the first elastic member and thesecond elastic member while telescoping in the axial direction. The first elastic member and the second elastic member cooperate to provide a pedal preset force to the brake pedal, and the output shaft of the booster motor cooperates with the one end of the overlapping portion of the first elastic member and the second elastic member through a screw mechanism so as to be able to provide the boosting force to the thrust structure. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

A brake pedal simulator, a vehicle braking system and a vehicle

ActiveCN109204264AReliable braking feelQuick responseFoot actuated initiationsOperational stabilityVehicle brake

A brake pedal simulator, a vehicle braking system and a vehicle are provided, wherein the brake pedal simulator includes a brake pedal, a booster motor, an assembly part for fitting to a vehicle body,a first elastic member and a second elastic member axially disposed on one side of the fitting portion and connected to each other, and a thrust structure hinged to the brake pedal and cooperating with the first elastic member to drive the first elastic member and the second elastic member while telescoping in the axial direction. The first elastic member and the second elastic member cooperate together to provide a pedal preset force to the brake pedal, and the output shaft of the booster motor is cooperated with the second elastic member through a screw mechanism to be able to provide a booster force for driving the thrust structure. The invention provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

A wind turbine braking device

ActiveCN109869272BHolding brake functionShorten speedWind motor controlMachines/enginesGear wheelControl theory

The invention discloses wind driven generator braking equipment. The equipment comprises a drum brake and a drum brake cavity formed in the drum brake. A body is arranged in the drum brake cavity, andinternally provided with a braking trigger cavity. A center threaded rod extending front and back is arranged in the braking trigger cavity and connected with a push block in a screw thread fit mode.The push block is connected with a lifting block in an abutting mode. The lifting block is connected with a lifting rod in a stationary fit mode. A gear and rack engaging cavity is formed above the braking trigger cavity. The invention aims at designing a device capable of performing braking on a wind driven generator when the rotating speed of the wind driven generator reaches a certain value soas to reduce the speed of the wind driven generator device.

Owner:青岛百恒新能源技术有限公司

Brake pedal simulators, car braking systems and vehicles

ActiveCN109204263BReliable braking feelBraking feels quickFoot actuated initiationsGear wheelElectric machinery

Owner:BYD CO LTD

A brake pedal simulator, a vehicle braking system and a vehicle

ActiveCN109204267AQuick responseFast braking feelFoot actuated initiationsOperational stabilityVehicle brake

A brake pedal simulator, a vehicle braking system and a vehicle are provided, wherein the brake pedal simulator includes a brake pedal, a booster motor, an assembly part for fitting to a vehicle body,a first elastic member and a second elastic member disposed axially on one side of the fitting portion and at least partially overlapping with each other in the axial direction, and a thrust structure hinged to the brake pedal and cooperating with one end of the overlapping portion of the first elastic member and the second elastic member to be capable of driving the first elastic member and thesecond elastic member while telescoping in the axial direction. The first elastic member and the second elastic member cooperate to provide a pedal preset force to the brake pedal, and the output shaft of the booster motor cooperates with the one end of the overlapping portion of the first elastic member and the second elastic member through a screw mechanism so as to be able to provide the boosting force to the thrust structure. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

A kind of manufacturing method of gradient composite material brake disc

The invention discloses a manufacturing method for a brake disc made of a gradient composite material. The manufacturing method comprises the following steps: assembling a low-pressure casting device,placing a reinforced-phase precast block, ascending liquid, strongly mixing, filling a mould, maintaining pressure, releasing pressure, taking parts and the like. The method is a novel and unique method in the gradient composite material and brake disc manufacturing method, is simple, convenient, and efficient, and can ensure the brake function of the outer periphery of the brake disc; and the connecting function of the inner periphery facilitates increasing a production rate and reducing the cost, so that the performance reliability of the brake disc is high.

Owner:镇江市吉玛铸造科技有限公司

Brake pedal simulator, car brake system and vehicle

ActiveCN109204271BReliable braking feelQuick responseFoot actuated initiationsElectric machineryControl theory

A brake pedal simulator, a vehicle braking system and a vehicle are provided, wherein the brake pedal simulator includes a brake pedal, a booster motor, an assembly part for fitting to a vehicle body,a first elastic member and a second elastic member arranged at axially spaced intervals on both sides of the fitting portion and connected to each other, and a thrust structure hinged to the brake pedal and cooperating with the first elastic member to drive the first elastic member and the second elastic member while telescoping in the axial direction. The first elastic member and the second elastic member cooperate together to provide a pedal preset force to the brake pedal, and the output shaft of the booster motor is cooperated with the second elastic member through a screw mechanism to beable to provide a booster force for driving the thrust structure. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

Brake pedal simulator, car braking system and vehicle

ActiveCN109204270BReliable braking feelBraking feels quickFoot actuated initiationsGear wheelElectric machinery

The present disclosure relates to a brake pedal simulator, an automobile braking system and a vehicle. The brake pedal simulator includes a brake pedal, a booster motor, an assembly part, a first elastic member arranged at intervals along the axial direction on both sides of the assembly part, and The second elastic member, the rack and pinion mechanism located between the two second elastic members, the thrust structure that is hinged to the brake pedal and can sequentially drive the first elastic member and the second elastic member to expand and contract in the axial direction, the first elastic member Provide pedal preset force for the brake pedal, the output shaft of the booster motor can cooperate with the second elastic member through the rack and pinion mechanism to provide power assistance for the driving of the thrust structure, and the first elastic member is compressed by the thrust mechanism in the first working state In the second working state, the first elastic member and the second elastic member are compressed synchronously through the cooperation of the thrust mechanism and the booster motor. Therefore, a reliable braking feeling of the brake pedal is provided to simulate an accurate brake pedal force, which has the effects of good operation stability and quick response of the brake pedal.

Owner:BYD CO LTD

Household cooking appliance comprising a receptacle containing a motor driven cutting tool

Owner:SEB SA

A brake pedal simulator, a vehicle braking system and a vehicle

ActiveCN109204271AReliable braking feelQuick responseFoot actuated initiationsOperational stabilityVehicle brake

A brake pedal simulator, a vehicle braking system and a vehicle are provided, wherein the brake pedal simulator includes a brake pedal, a booster motor, an assembly part for fitting to a vehicle body,a first elastic member and a second elastic member arranged at axially spaced intervals on both sides of the fitting portion and connected to each other, and a thrust structure hinged to the brake pedal and cooperating with the first elastic member to drive the first elastic member and the second elastic member while telescoping in the axial direction. The first elastic member and the second elastic member cooperate together to provide a pedal preset force to the brake pedal, and the output shaft of the booster motor is cooperated with the second elastic member through a screw mechanism to beable to provide a booster force for driving the thrust structure. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

A brake pedal simulator, a vehicle braking system and a vehicle

ActiveCN109204265AReliable braking feelQuick responseFoot actuated initiationsOperational stabilityRack and pinion

A brake pedal simulator, a vehicle braking system and a vehicle are provided, wherein the brake pedal simulator includes a brake pedal, a booster motor, an assembly part for fitting to a vehicle body,a first elastic member and a second elastic member arranged at axially spaced intervals on both sides of the fitting portion, a rack and pinion mechanism located between the first elastic member andthe second elastic member, and a thrust structure hinged to the brake pedal and cooperating with the first elastic member to drive the first elastic member and the second elastic member while telescoping in the axial direction. The first elastic member and the second elastic member cooperate together to provide a pedal preset force to the brake pedal, and the output shaft of the booster motor cooperates with the first elastic member and the second elastic member through a rack and pinion mechanism to be able to provide a driving force for the thrust structure. This provides a reliable brakingfeel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

Grouped multi-axle trailer braking system

ActiveCN110962821BReduce wearHolding brake functionBraking action transmissionBrake safety systemsControl theoryParking brake

The invention discloses a grouped multi-axle trailer braking system, wherein, utilizing the characteristics of the four-circuit protection valve, the multi-axis trailer braking system is divided into multiple groups of independent 2-axis braking systems using the four-circuit protection valve. If an independent part of the brake pipeline is damaged, only the braking system of this group is affected, and the functions of other braking systems can still guarantee the braking function. In addition, the only manual parking valve is used to uniformly control the parking release control air circuit, so that Manual parking is still only controlled by the only manual parking valve, and an independent parking release air storage tank is also used. When the air source fails or other air storage tanks fail, it is guaranteed to have the function of releasing the parking brake at least once. With ABS anti-lock function, the braking function has strong reliability and stability, and the adaptive ability of different suspension loads and braking force reduces tire wear and improves the safety during driving.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

Brake pedal simulator, car braking system and vehicle

ActiveCN109204265BReliable braking feelQuick responseFoot actuated initiationsGear wheelElectric machinery

The present disclosure relates to a brake pedal simulator, an automobile brake system and a vehicle, wherein the brake pedal simulator includes a brake pedal, a booster motor, an assembly part for assembling on a vehicle body, arranged at intervals along the axial direction The first elastic piece and the second elastic piece on both sides of the assembly part, the rack and pinion mechanism located between the first elastic piece and the second elastic piece, are hinged to the brake pedal and cooperate with the first elastic piece to be able to drive the first The thrust structure in which the elastic part and the second elastic part expand and contract in the axial direction at the same time. The first elastic part and the second elastic part work together to provide the pedal preset force for the brake pedal. The output shaft of the booster motor connects with the second The first elastic member cooperates with the second elastic member to provide assistance for driving the thrust structure. Therefore, a reliable braking feeling of the brake pedal is provided to simulate an accurate brake pedal force, which has the effects of good operation stability and quick response of the brake pedal.

Owner:BYD CO LTD

Brake pedal simulator, car braking system and vehicle

ActiveCN109204268BReliable braking feelBraking feels accurateFoot actuated initiationsElectric machineryControl theory

A brake pedal simulator, a vehicle braking system and a vehicle are provided. The brake pedal simulator includes a brake pedal, a booster motor, an assembly portion, a first elastic member and a second elastic member disposed on one side of the assembly portion in the axial direction and partially overlapping with each other in the axial direction, and a thrust structure hinged to the brake pedaland cooperating with the first elastic member to sequentially drive the first elastic member and the second elastic member to telescopically retract in the axial direction. The first elastic member provides a pedal preset force to the brake pedal, the output shaft of the booster motor is cooperated with the first elastic member through a screw mechanism to be able to provide power to the thrust structure, the first elastic member is compressed through the thrust mechanism in a first working state, and the first elastic member and the second elastic member are compressed synchronously through the cooperation of the thrust mechanism and the booster motor in a second working state. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

Brake pedal simulator, car brake system and vehicle

A brake pedal simulator, a vehicle braking system and a vehicle are provided. The brake pedal simulator includes a brake pedal, a booster motor, an assembly part for fitting to a vehicle body, a firstelastic member and a second elastic member axially disposed on one side of the fitting portion and at least partially overlapping with each other in the axial direction, and a thrust structure hingedto the brake pedal and cooperating with one end of the overlapping portion of the first elastic member and the second elastic member to be capable of driving the first elastic member and the second elastic member while telescoping in the axial direction, The first elastic member and the second elastic member cooperate to provide a pedal preset force to the brake pedal, and the output shaft of thebooster motor cooperates with one end of the overlapping portion of the first elastic member and the second elastic member through a rack-and-pinion mechanism so as to be able to provide a boosting force to the thrust structure. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

Brake pedal simulators, car braking systems and vehicles

ActiveCN109204264BReliable braking feelQuick responseFoot actuated initiationsElectric machineryControl theory

A brake pedal simulator, a vehicle braking system and a vehicle are provided, wherein the brake pedal simulator includes a brake pedal, a booster motor, an assembly part for fitting to a vehicle body,a first elastic member and a second elastic member axially disposed on one side of the fitting portion and connected to each other, and a thrust structure hinged to the brake pedal and cooperating with the first elastic member to drive the first elastic member and the second elastic member while telescoping in the axial direction. The first elastic member and the second elastic member cooperate together to provide a pedal preset force to the brake pedal, and the output shaft of the booster motor is cooperated with the second elastic member through a screw mechanism to be able to provide a booster force for driving the thrust structure. The invention provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

Brake pedal simulator, car brake system and vehicle

ActiveCN109204272BReliable braking feelBraking feels quickFoot actuated initiationsGear wheelElectric machinery

A brake pedal simulator, a vehicle braking system and a vehicle are provided. The brake pedal simulator includes a brake pedal, a booster motor, an assembly portion, a first elastic member and a second elastic member disposed on one side of the assembly portion in the axial direction and partially overlapping with each other in the axial direction, and a thrust structure hinged to the brake pedaland cooperating with the first elastic member to sequentially drive the first elastic member and the second elastic member to telescopically retract in the axial direction. The elastic resilient member provides a pedal preset force to the brake pedal, The output shaft of the booster motor is cooperated with the first elastic member through a rack and pinion mechanism so as to be able to provide assistance to the thrust structure, the first elastic member is compressed through the thrust mechanism in a first working state, and the first elastic member and the second elastic member are compressed synchronously through the cooperation of the thrust structure and the booster motor in a second working state. This provides a reliable braking feel of the brake pedal and simulates an accurate brake pedal force, and has the effects of good operation stability and corresponding quick brake pedal.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com