Image forming apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

An image forming apparatus according to the present invention will be described below with reference to the accompanying drawings. Note that the image forming apparatus of this embodiment is so designed as to be able to record a desired image on a sheet of a predetermined size, and it is possible to use, e.g., recording paper, a sheet of paper, a plastic film, or cloth as the sheet.

The embodiment will be described below by taking an image forming apparatus using a sheet of paper as an image recording sheet as an example.

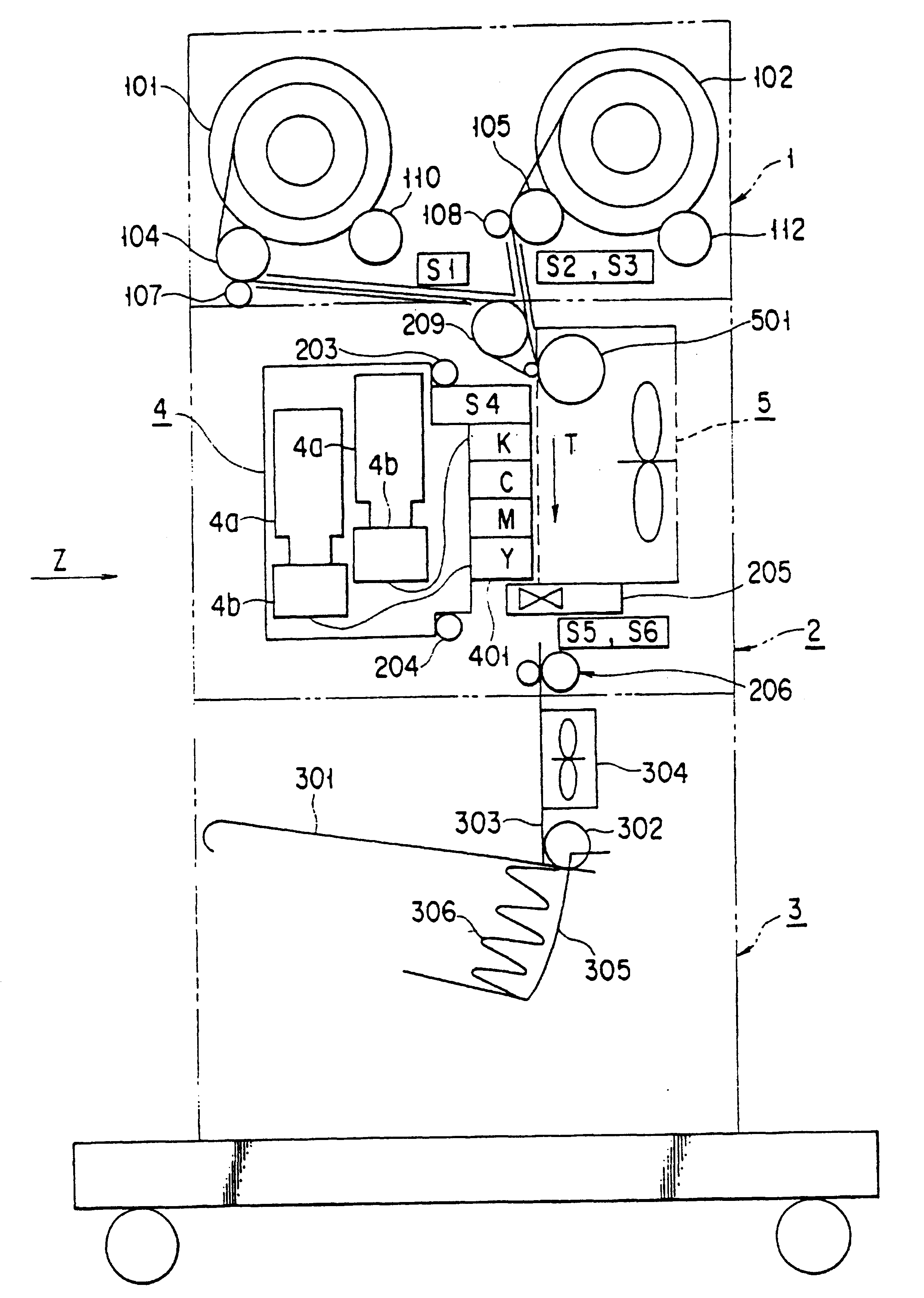

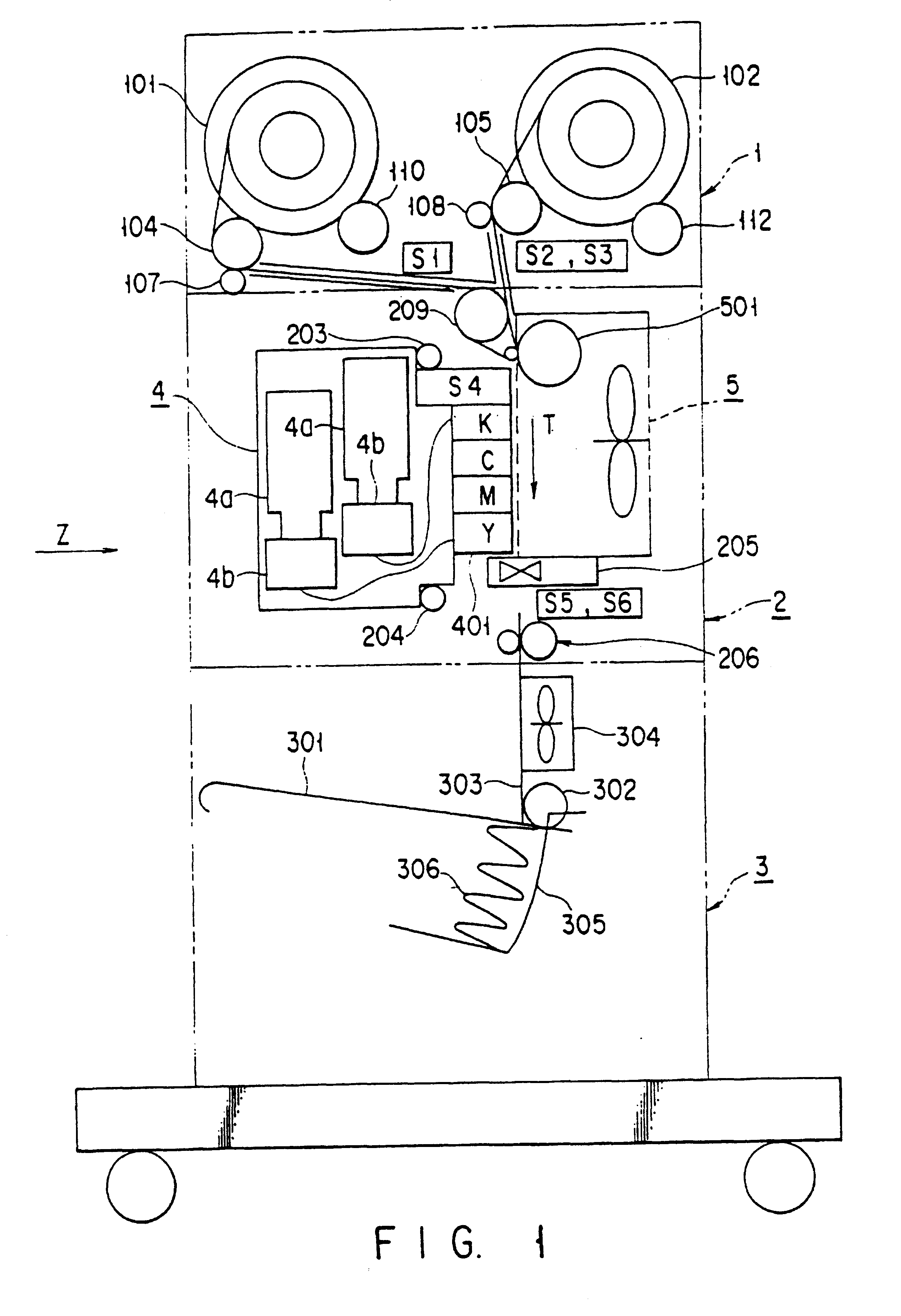

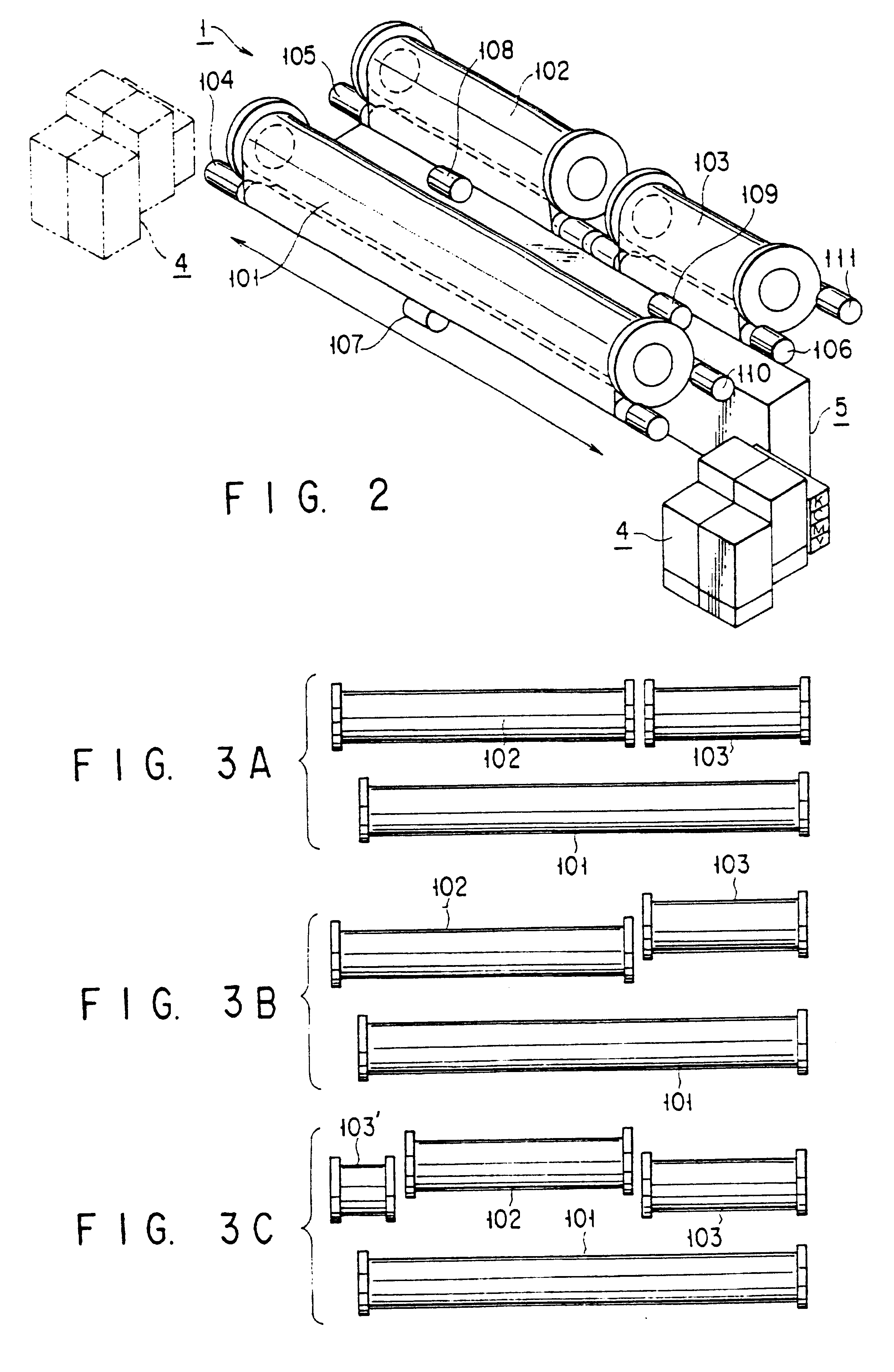

As shown in FIG. 1, the image forming apparatus of this embodiment includes a paper feed station 1, a recording station 2, and a processing station 3. The paper feed station 1 can accommodate a plurality of roll sheets each formed by winding a sheet of a predetermined size into a roll (although only two roll sheets 101 and 102 are shown in FIG. 1, this embodiment uses first, second, and third roll sheets 101, 102, and 103 as shown in FIG. 2). The recording station 2 ...

second embodiment

An image forming apparatus according to the present invention will be described below. The image forming apparatus of this embodiment is so designed as to be able to record a desired image on a sheet of a predetermined size. It is possible to use, e.g., recording paper, a sheet of paper, a plastic film, or cloth as the sheet.

In the following explanation, an image forming apparatus using a sheet of paper as an image recording sheet will be described as an example.

As shown in FIGS. 21 and 22, the image forming apparatus of this embodiment includes a paper feed station 1, a recording station 2, and a processing station (not shown). The paper feed station 1 can accommodate a plurality of roll sheets each formed by winding a sheet of a predetermined size into a roll. The recording station 2 records a desired image on a sheet fed from the paper feed station 1. The processing station delivers the sheet on which the image is recorded by the recording station 2.

In this embodiment, it is assu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com