Secondary battery power storage system

a secondary battery and battery technology, applied in the direction of secondary cell propulsion, battery/fuel cell control arrangement, battery/cable servicing/maintenance, etc., can solve the problems of inability to determine the residual capacity of nickel-cadmium batteries and nickel-metal hydride batteries, safety problems, etc., to secure the soundness of batteries, and prevent overdischarge of secondary batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

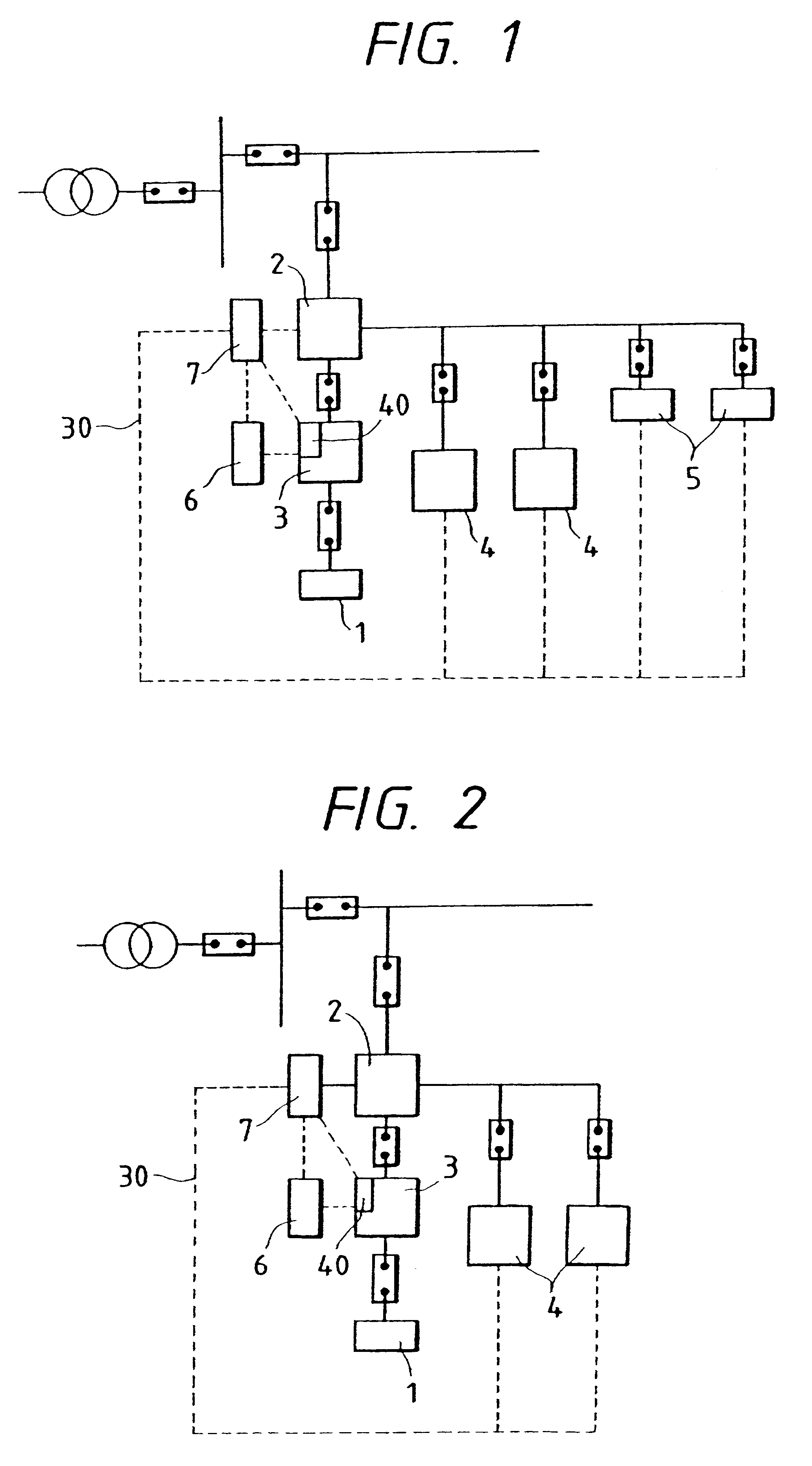

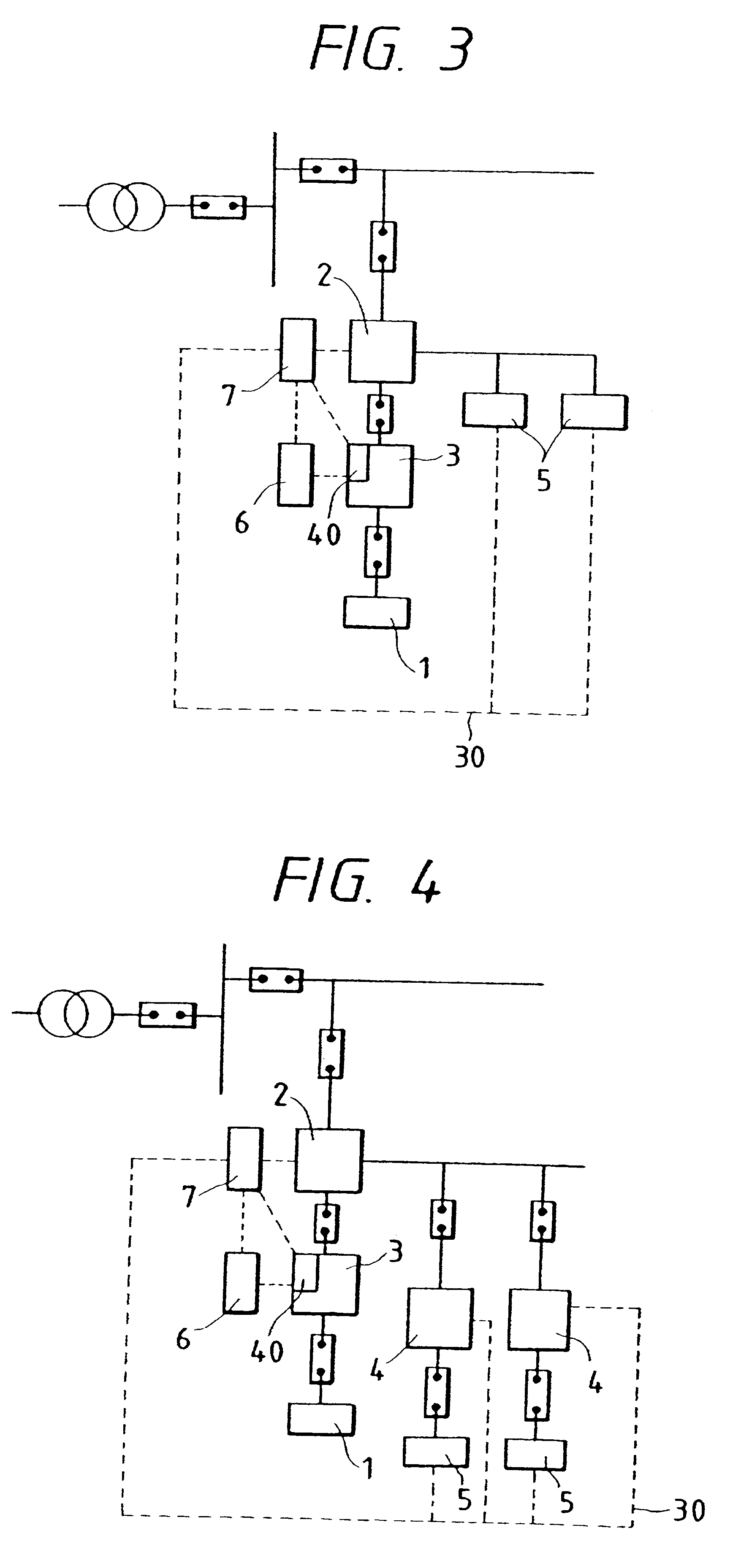

FIG. 1 shows a secondary battery electric power storage system in a first embodiment according to the present invention. Although the first embodiment is one of the best modes for carrying out the invention, the present invention is not limited thereto. Referring to FIG. 1, a secondary battery load 1, and a connection unit 2 connectable to a power system are connected to a secondary battery 3. A plurality of electric power storage units 4 are placed in parallel combination with the connection unit 2 connected to a power supply system. A plurality of loads 5 are connected to the charge / discharge unit 2 or the electric power storage units 4. A signal line 30 indicated by broken lines, is connected to a controller 7 included in the connection unit 2. Detecting device 40 detects residual electric power in the secondary battery.

When necessary, the secondary battery electric power storage system is provided with a means, not shown in FIGS. 1 to 4, for supplying electric power directly fro...

second embodiment

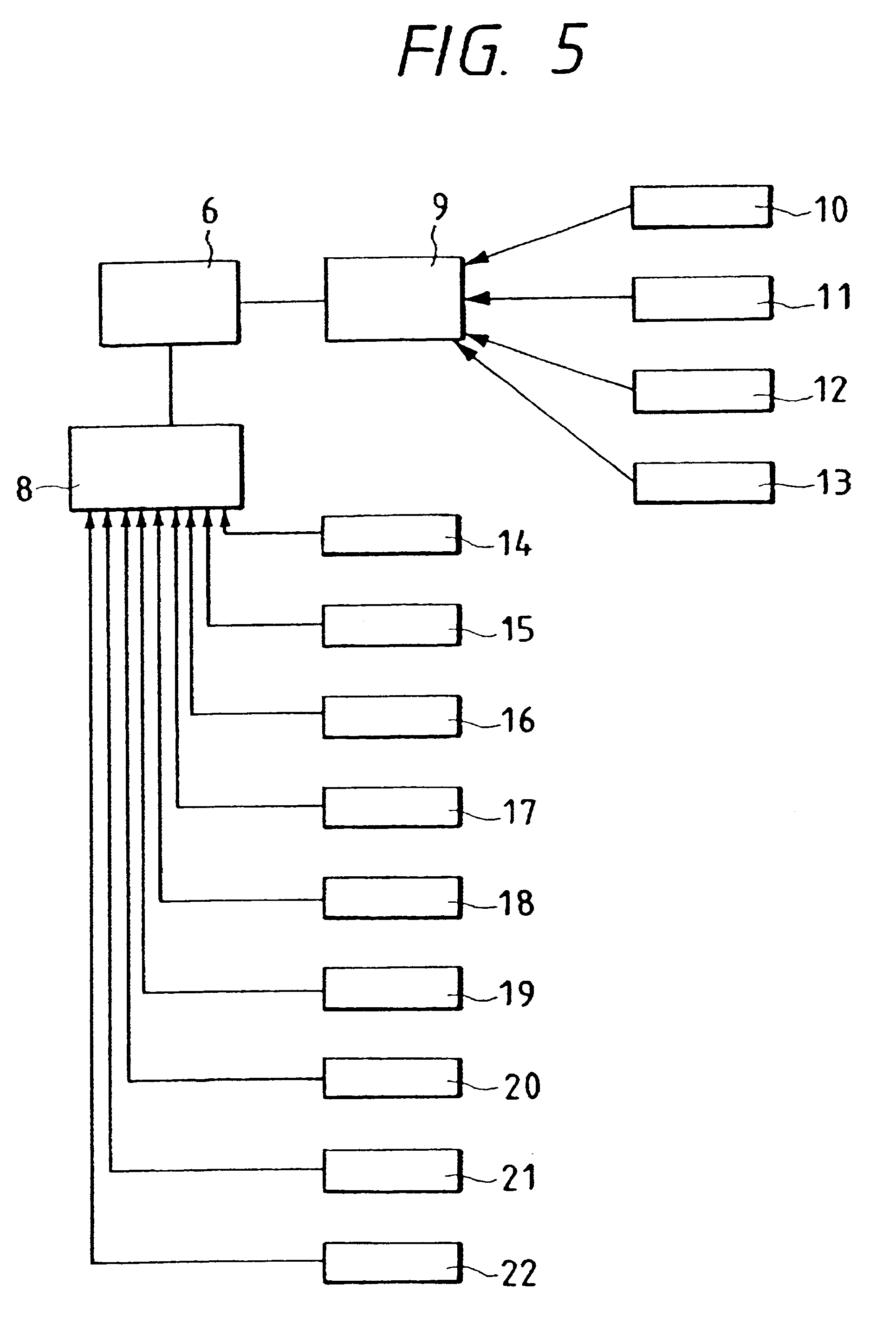

FIG. 5 is a flow chart of a control procedure to be carried out by the controllers 6 of the secondary batteries 3 of FIGS. 1 to 4. The control procedure will be described hereinafter with reference to FIGS. 1 to 5. The secondary battery 3 is provided with the controller 6, an A / D converter 8 and a memory 9. The memory 9 is capable of storing standard characteristic data on the intrinsic characteristics of the secondary battery 3 including charging efficiency 10, discharging efficiency 11, temperature characteristics 12 and optimum charge and discharge conditions 13. The optimum charge and discharge conditions 13 specify charge and discharge modes, such as a constant-current charge mode, constant discharge mode, a constant-voltage discharge mode and a constant-voltage discharge mode, currents and voltages, cut voltages, charge capacities, discharge capacities, charge times and discharge times.

When the secondary battery 3 is connected to the charge / discharge unit 2 for charging, the s...

third embodiment

When a secondary battery 3 is a nickel-cadmium battery or a nickel-metal hydride battery, a controller 6 controls the secondary battery 3 for discharging so that 95% to 100% of a discharge capacity corresponding to an available discharge capacity is discharged in a mode conforming to optimum discharge conditions when the residual capacity is 0 to 85% of the charge capacity of the secondary battery 3.

If the residual capacity is 85% or above of the charge capacity, surplus electric power discharge is not performed. When the secondary battery 3 is a lithium battery, the controller 6 controls the secondary battery 3 so that 80% to 95% of a discharge capacity corresponding to an available discharge capacity is discharged in a mode conforming to optimum discharge conditions when the residual capacity is 5% to 80% of the charge capacity. When the residual capacity is 5% or below of the charge capacity, surplus electric power discharge is not performed. When the residual capacity is 80% or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual electric power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| electric power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com