Cell aggregation and encapsulation device and method

a cell culture and cell technology, applied in the field of cell culture aggregation and encapsulation devices and methods, can solve the problems of unable to scale up the technique, unable to replenish or change the composition of the culture medium or add new cells to the aggregates in the hanging drops, and hampered the laboratory study of cells and groups of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Cell Aggregation Device Fabrication and Cell Culture Preparation

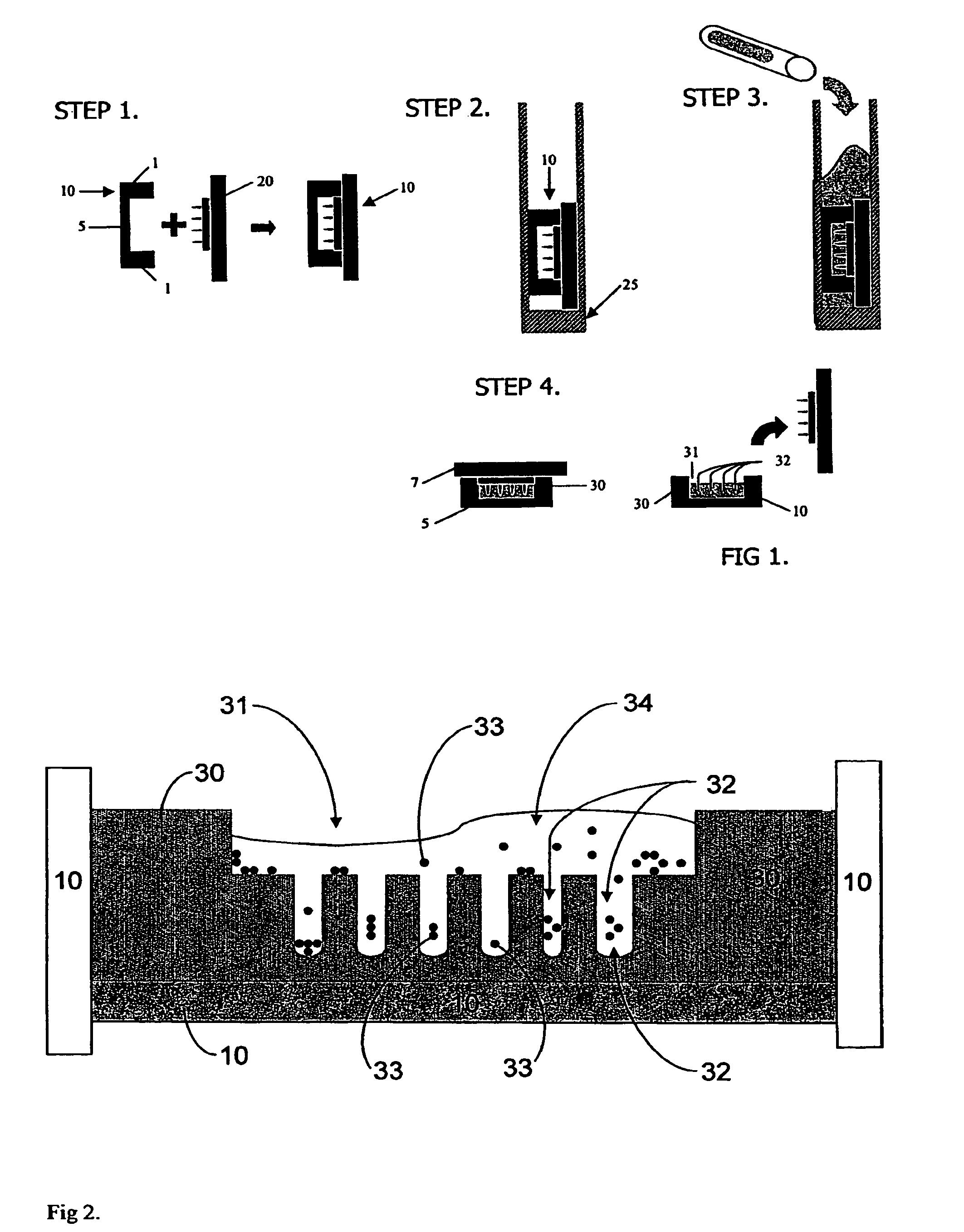

[0082]The fabrication method is illustrated for a general device of the invention in FIG. 1. Thirty millimeter Millicell® CM cell culture inserts 10 (Millipore), which are essentially rigid plastic rings 1 having porous polytetrafluoroethylene (PTFE) membranes 5 on their bottoms, were employed as mold templates. The PTFE membrane, which is transparent when wet, permits diffusion of culture media and visualization of cell aggregates through an inverted microscope. AutoCAD 2005® software was employed to design the shape and contours of various cell aggregation devices and polyacrylamine substrates were made from the wax templates by rapid prototype printing of sequential layers of wax to create the desired 3D CAD designed topography. Mold topography was designed such that gravitational force could funnel cells into the aggregation wells. The wax template was designed to produce a flat square recess 1 mm in depth from the ...

example 2

Cell Seeding and Aggregation of Human Diploid Fibroblasts

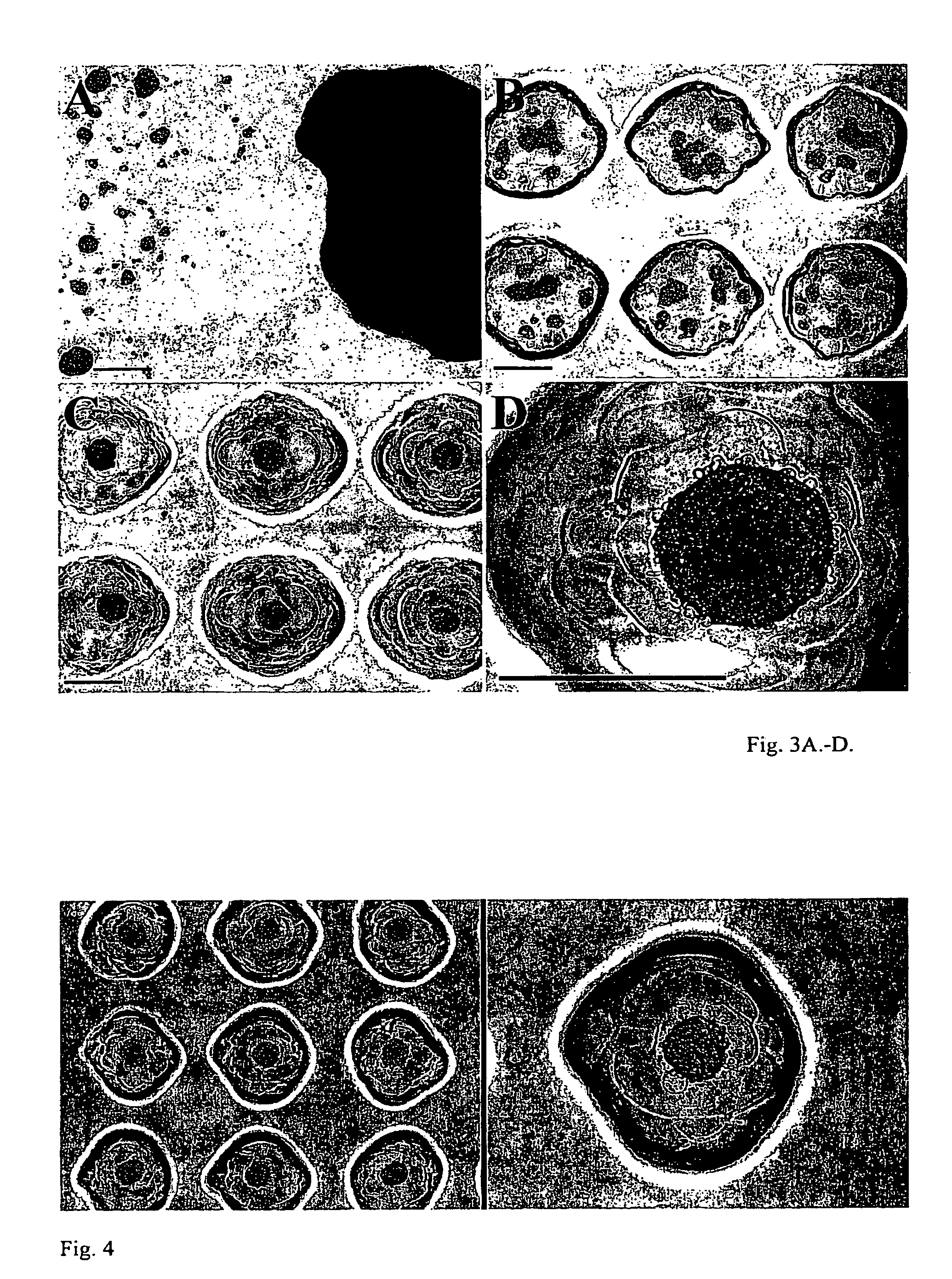

[0086]3 ml of cell culture media (DMEM supplemented with 1% penicillin / streptomycin as antibiotic, with and without fetal bovine serum) was added to and the plates transferred to a cell culture incubator and allowed to equilibrate overnight to rinse out any unreacted monomer, neutralize pH and fill the pores of device 30 with the media. In a biological safety cabinet, excess media was aspirated out of the 6-well tissue culture plates. Normal human diploid fibroblast cells were trypsinized, counted and resuspended to a cell density of 1.67 million cells per ml. 300 μl (i.e., about 500,000 cells) were pipetted into each seeding chamber. FIG. 2 illustrates the cells 33, in various stages of the process of entering the aggregation recesses 32, are shown bathed media 34, just after being pipetted into one of the seeding chambers.

[0087]The hydrogel cell aggregation devices were transferred to the incubator for about 1.5 hours to all...

example 3

Aggregation of a Mixed Population of HUVEC and Fibroblasts

[0089]Human umbilical cord vascular endothelial cells (HUVEC) were seeded alone and simultaneously in co-culture with normal human diploid fibroblasts, the latter of which were also seeded alone. To visualize the different cell types, Cell Tracker™ fluorescent living cell stain was used. A freshly trypsinized suspension of HUVECs was incubated in 5 μM green fluorescent Cell Tracker™ (in cell culture medium) and a fibroblast suspension was incubated in 5 μM red fluorescent Cell Tracker™ for 45 minutes. Cell suspensions were centrifuged, Cell Tracker™ was aspirated off, and the cells were re-suspended in fresh media and incubated for 30 minutes.

[0090]Cell suspensions were then seeded into the seeding chambers of the aggregation devices made in accordance with Example 1 above. 0.50 million HUVECs alone (homogeneous population), 0.50 million fibroblasts alone (homogeneous population) and 0.25 million HUVEC and 0.25 million fibrob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com