Chemical liquid supplying apparatus and pump assembly

a technology of chemical liquid and supplying apparatus, which is applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of inability to discharge chemical liquid with high precision, decrease in the amount of incompressible medium, and progress of so as to prevent abrasion of seal members, prevent leakage of indirect medium, and increase the lubrication characteristic of seal members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

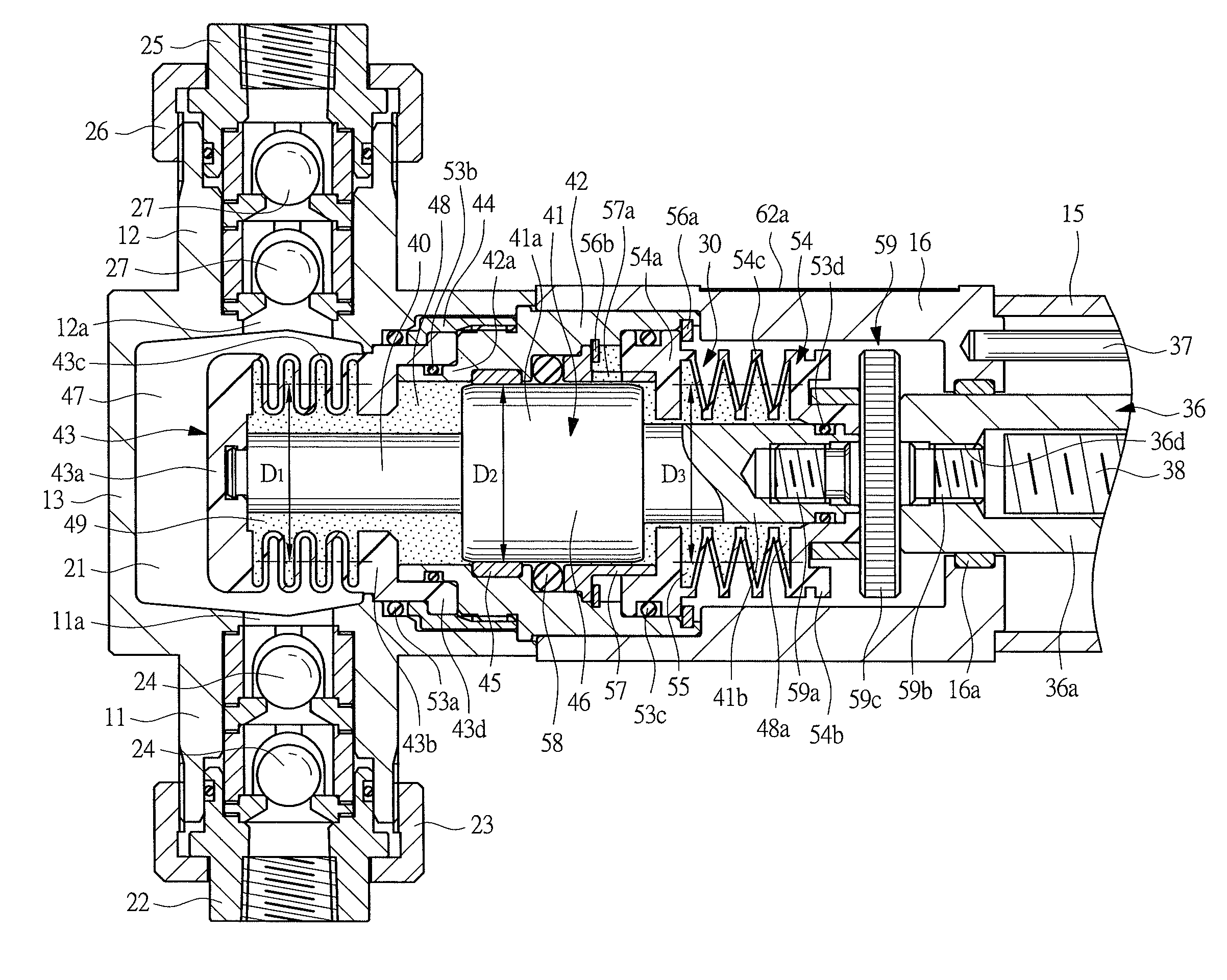

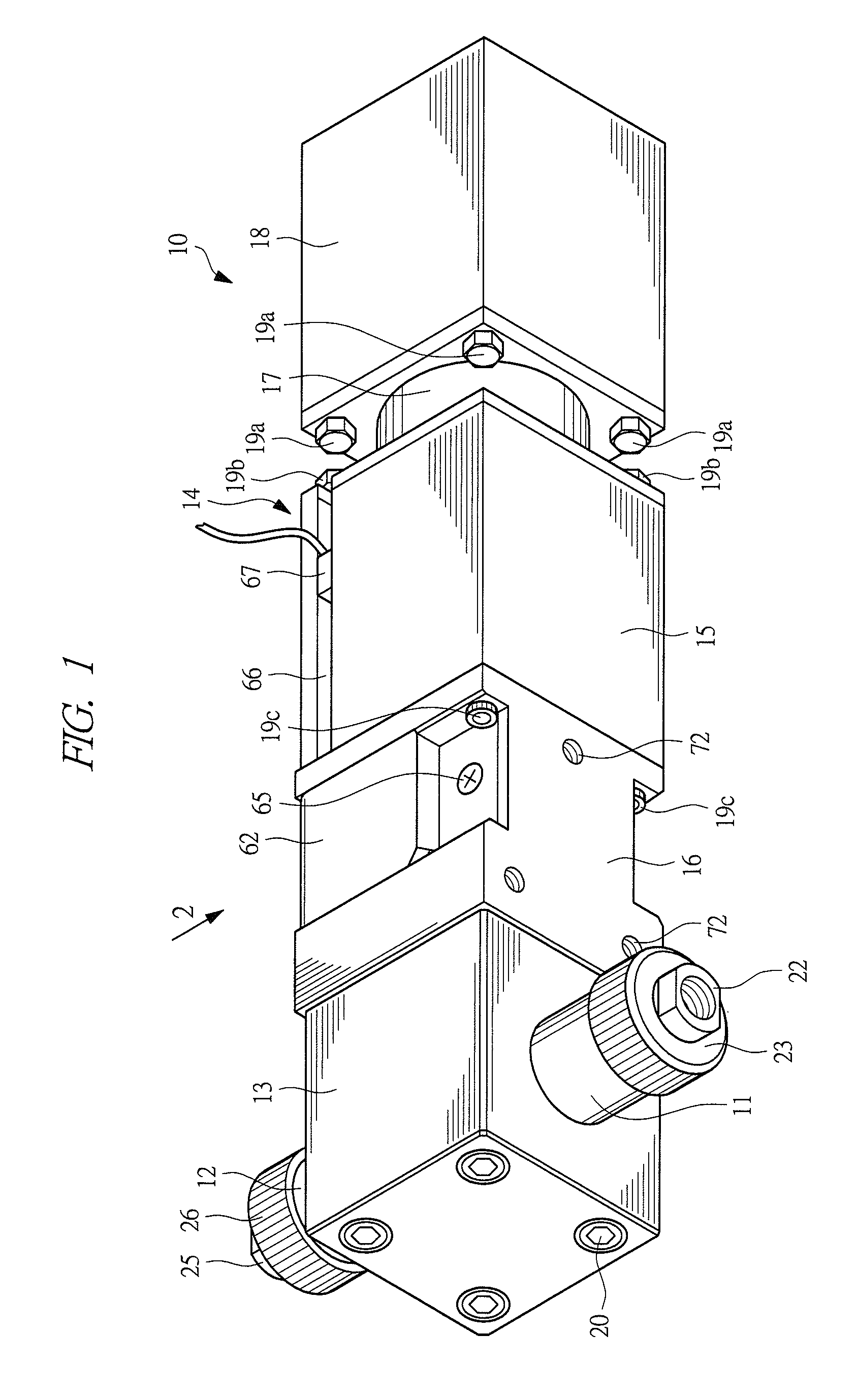

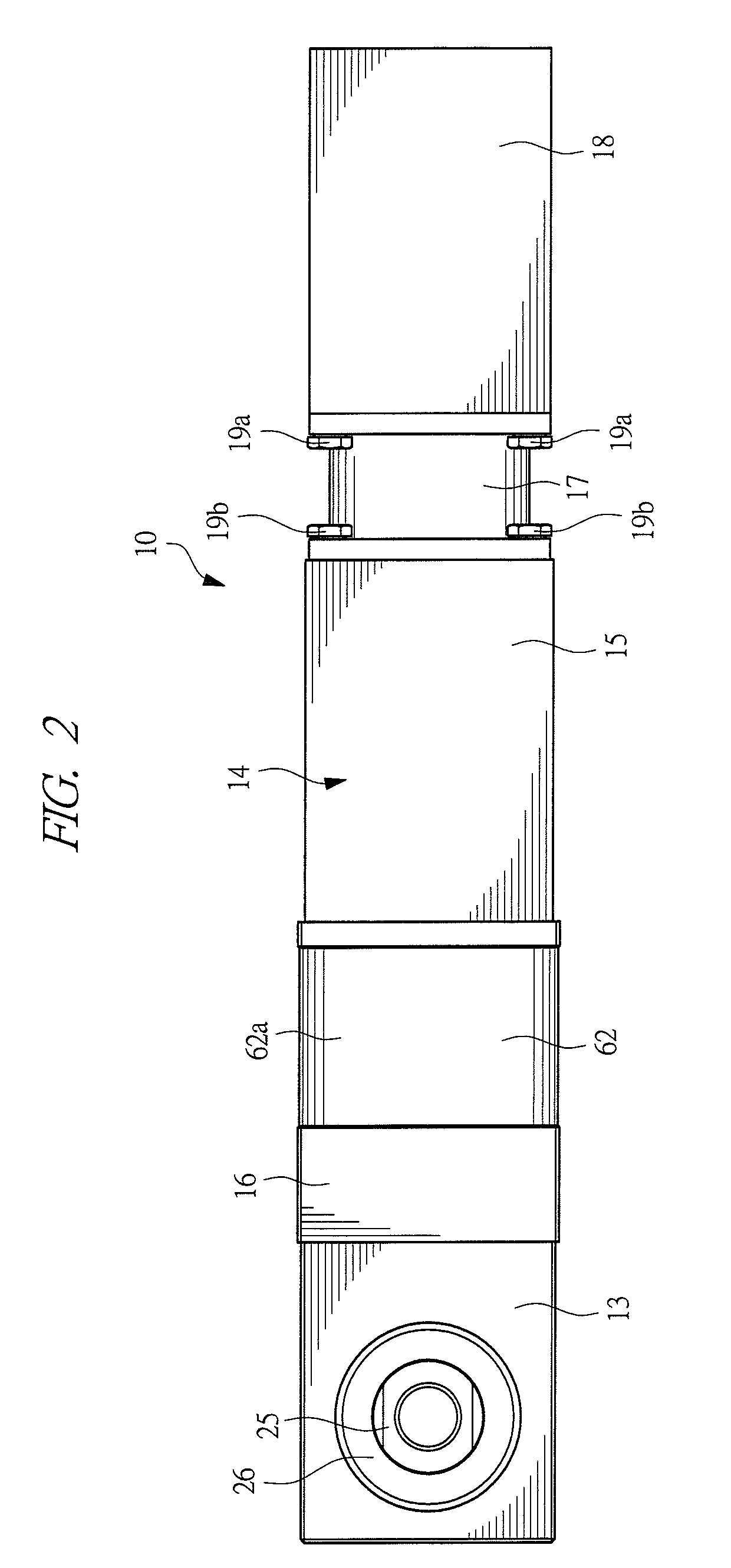

[0037]Hereinafter, embodiments according to the present invention will be described in detail with reference to the accompanying drawings. FIG. 1 is a perspective view showing external appearance of a chemical liquid supplying apparatus according to an embodiment of the present invention; FIG. 2 is a plane view of the chemical liquid supplying apparatus viewed from an arrow 2 in FIG. 1; FIG. 3 is an enlarged sectional view showing a portion of a front-side half of FIG. 1; FIG. 4 is an enlarged sectional view showing a rear-side half of FIG. 1; and FIG. 5 is an exploded sectional view of the chemical liquid supplying apparatus.

[0038]A chemical liquid supplying apparatus 10 has, as shown in FIG. 1, a substantially rectangular parallelepiped-shaped pump case 13 provided integrally with a liquid inflow portion 11 and a liquid discharge portion 12, each of which is formed into a cylindrical shape, and this pump case 13 is detachably mounted on a drive unit 14. The drive unit 14 has a sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com