Glycoconjugates and their use as potential vaccines against infection by Shigella flexneri

a technology of shigella flexneri and glycoconjugate, which is applied in the field of eliciting an immunogenic response in mammals, can solve the problems of not being able to improve rapidly and the control of these parameters is somewhat difficult, so as to prevent, treat, or ameliorate infection and disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Oligo- and Polysaccharides:

[0044]This invention provides a synthetic, semi-synthetic, natural, modified-natural or recombinant oligo- or polysaccharide containing subunits from the list L1.

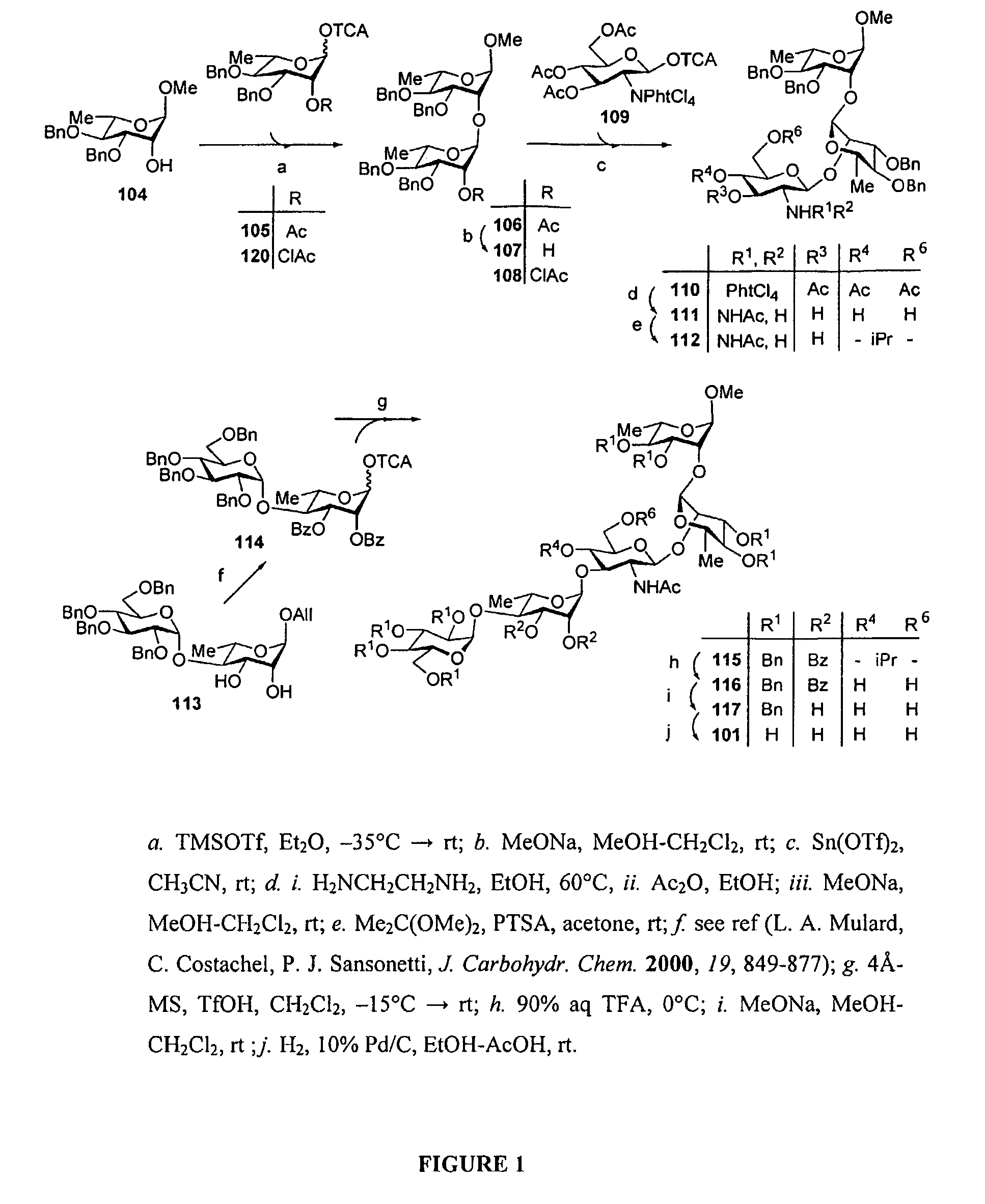

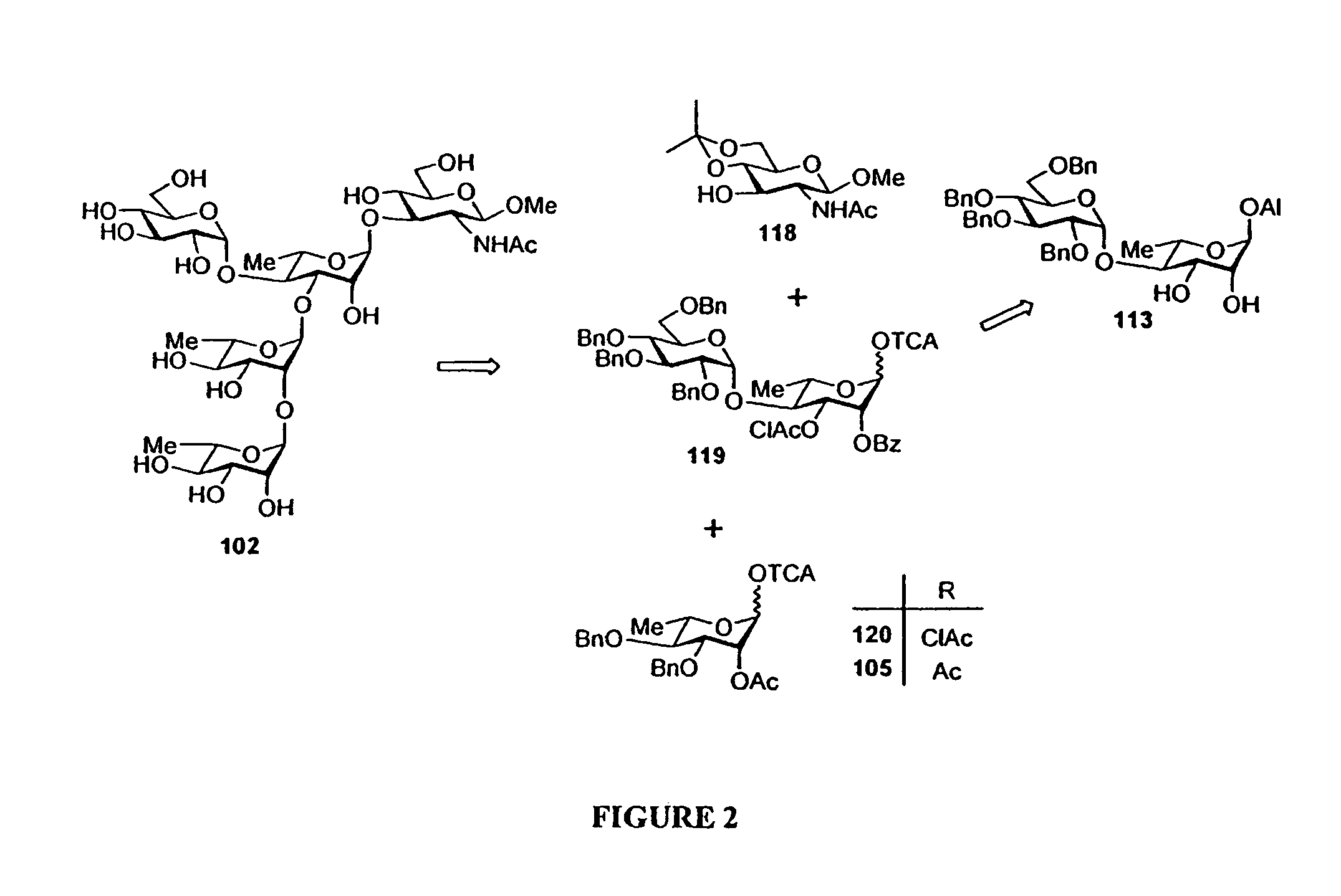

[0045]Methods for synthesizing S. flexneri 2a di- tri-, tetra, penta and octasaccharides are know from the prior art (F. Segat Dioury et al., Tetrahedron Asymmetry, 13, 2002, 2211-2222; C. Costachel et al., J. Carbohydrate Chemistry, 19(9) 2000, 1131-1150; L. Mulard et al., J. Carbohydrate Chemistry, 19(7), 2000, 849-877 F. Belot et al., Tetrahedron Letters, 43, 2002, 8215-8218; L. Mulard et al., Tetrahedron 58, 2002, 2593-2604; L. Mulard et al., J. Carbohydrate Chemistry, 19(2), 2000, 193-200).

[0046]An improved method to synthesize oligo- or polysaccharides is set forth in the examples below. Notably the synthesis of a decasaccharide was performed by condensation of two pentasaccharide intermediates.

DEFINITIONS

[0047]“oligosaccharide” as defined herein, is a carbohydrate containing from two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com