Rare earth element-doped oxide precursor with silicon nanocrystals

a technology of rare earth elements and precursors, applied in semiconductor/solid-state device manufacturing, basic electric elements, electric devices, etc., can solve the problems of low device efficiency, increased cost, and insufficient interface engineering to support the use of rare earth element-doped oxide precursors, etc., to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

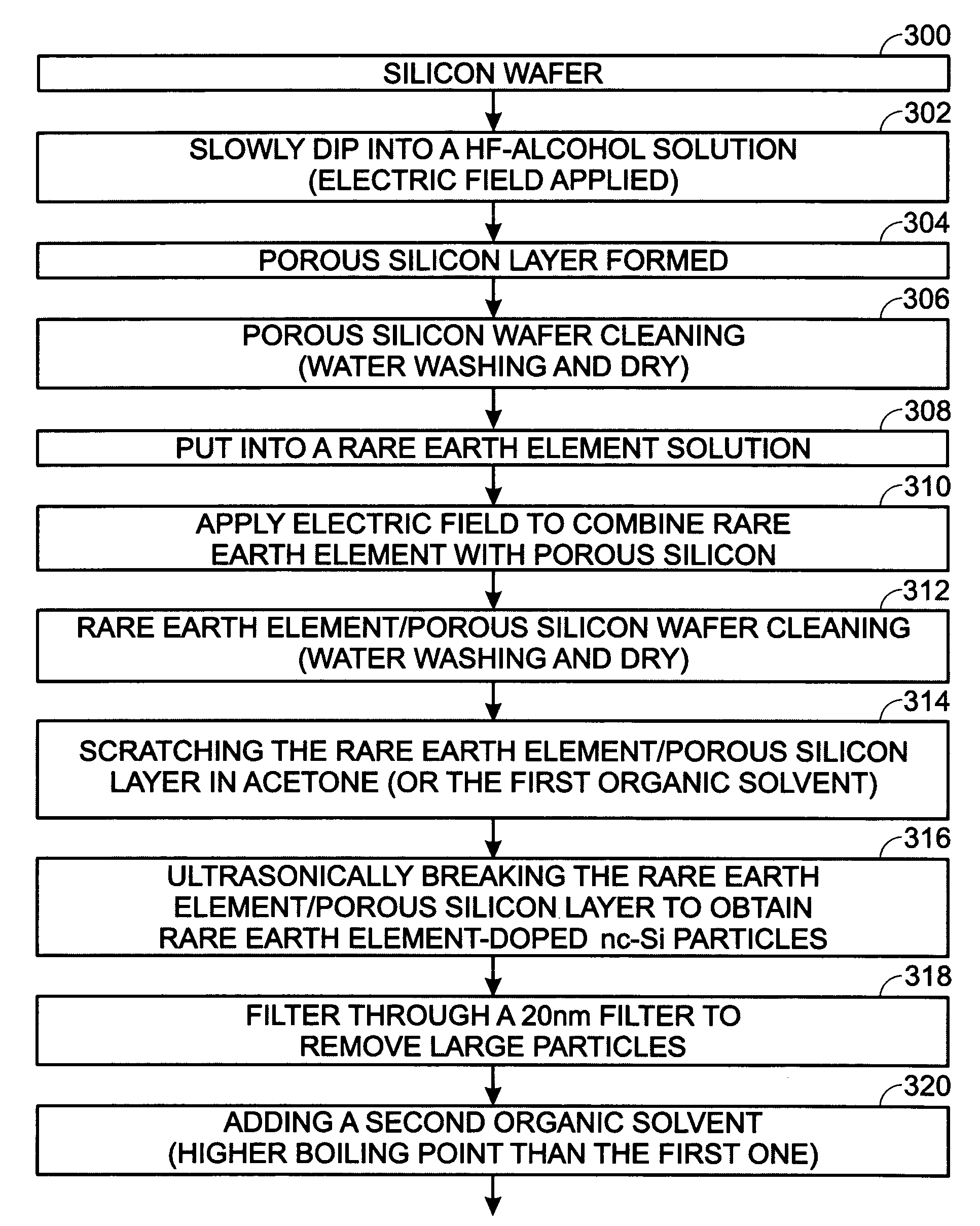

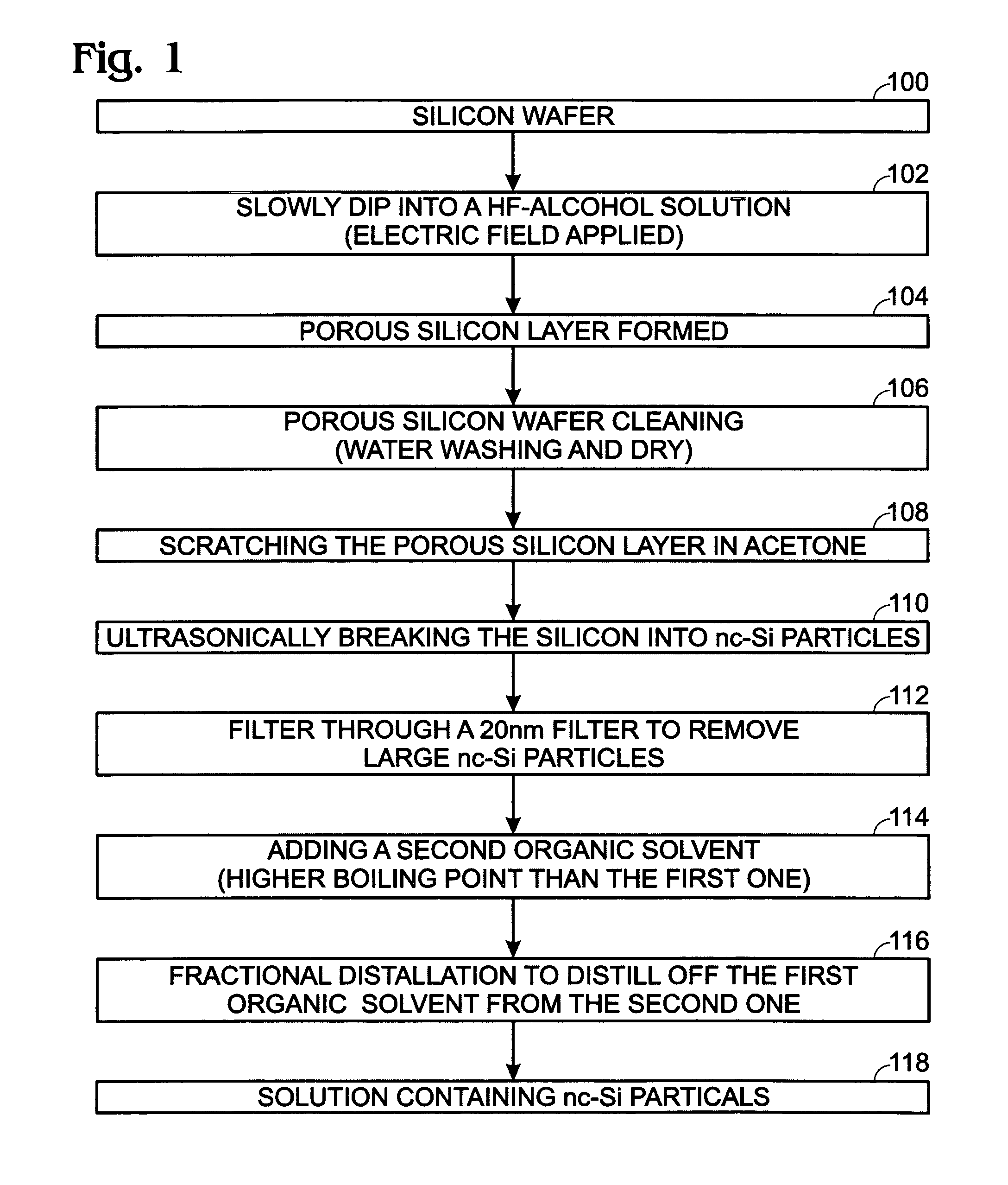

[0022]FIG. 1 is a diagram depicting a process for forming a nc Si solution. The synthesis of nc Si particles includes four basic steps. In the first basic step (Steps 100-108), a porous silicon layer is formed through an electrochemical etch process. The solution for the electrochemical process is the mixture of HF( about 49%) and alcohol, such as the methanol or ethanol. The porous silicon layer is formed by slowly immersing the wafer into the solution while keeping an electrical bias on the wafer. The thickness of the resulting porous silicon layer depends on the immersion speed, current density, solution concentration, and wafer properties.

[0023]The second step (Step 110) is the transfer of the porous silicon layer into an organic solvent. An ultrasonic treatment can be used in the step to separate the porous silicon layer from the wafer. The solvents used in this step include a strong polar organic solvent, such as acetone or tetrahydrofuran.

[0024]After transfer, the nc Si parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com