Semi-solid forming of metal-matrix nanocomposites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

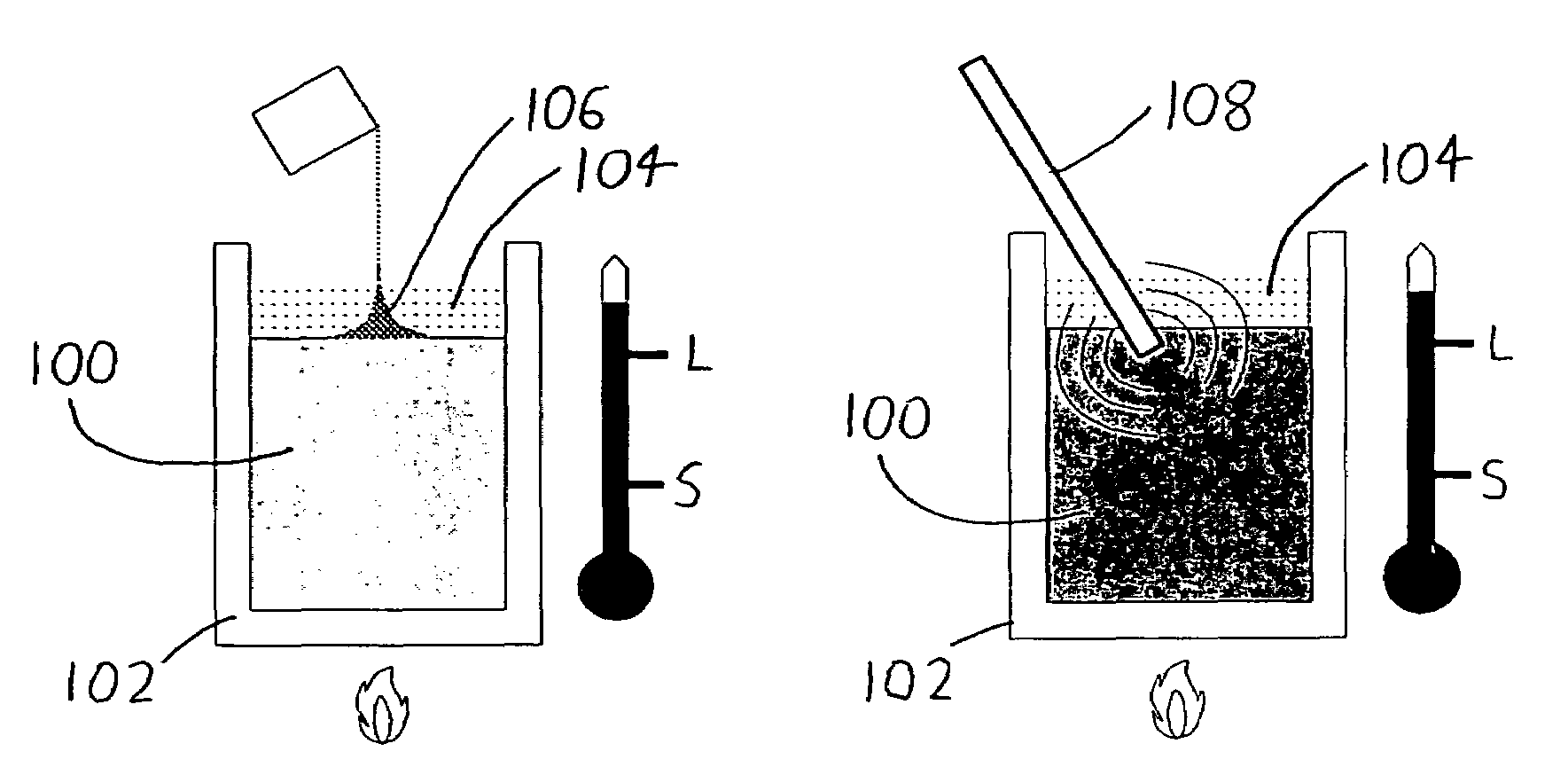

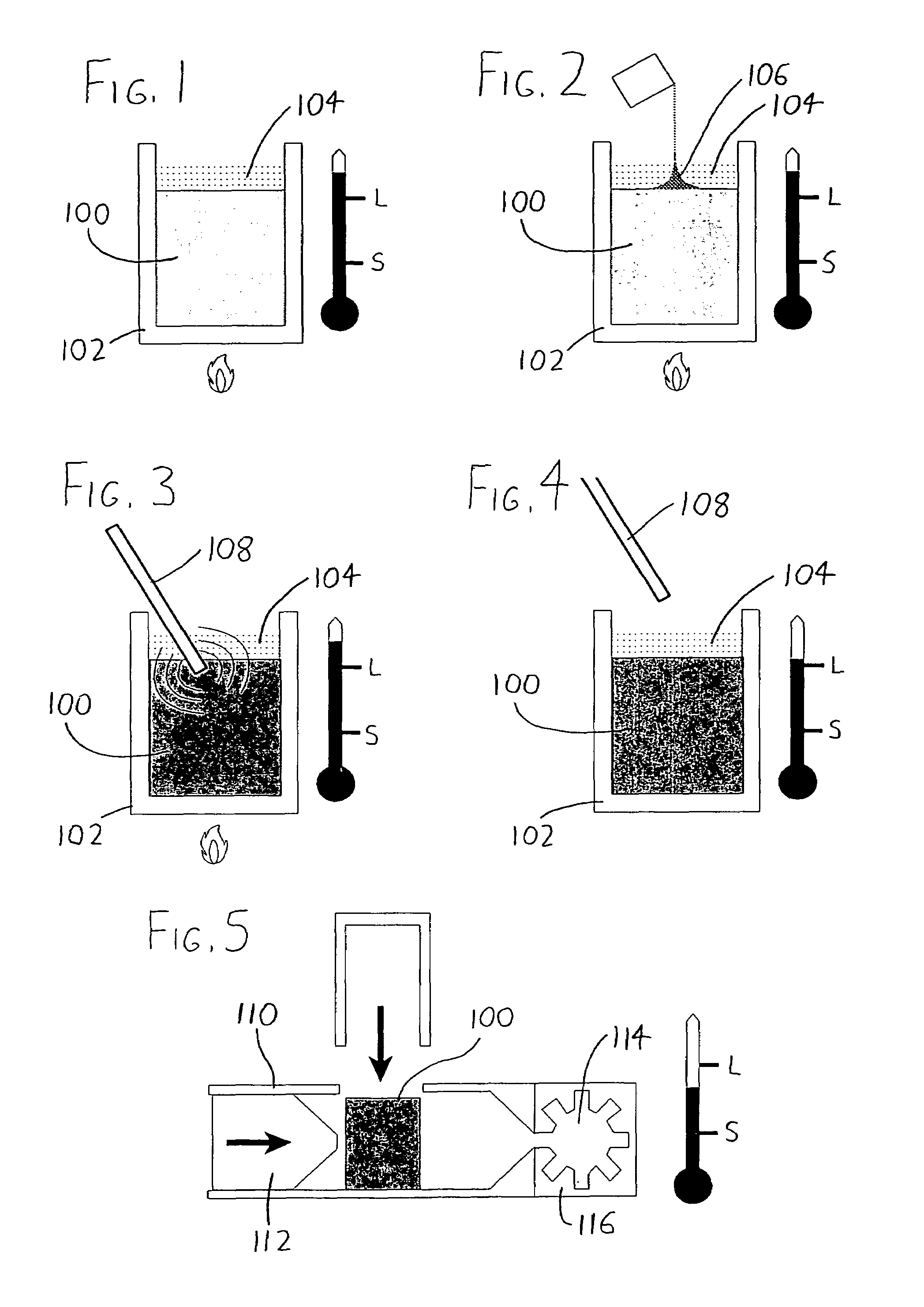

[0021]To expand on the discussion above, following is a more detailed explanation of an exemplary method for forming a metal matrix nanocomposite, with reference being made to the accompanying drawings.

[0022]First, referring to FIG. 1, a metal 100 is brought to a temperature above its liquidus (preferably at least 50 C above). This can be done in any conventional manner, e.g., in a graphite crucible 102 using an electric resistance furnace. If desired, a cover gas 104 may be used to reduce oxidation of the molten metal 100.

[0023]As depicted in FIG. 2, nanoparticles 106 may then be added to the molten metal 100, preferably by simply applying them atop the surface of the metal 100. To promote faster mixing of the metal 100 and nanoparticles 106 during subsequent steps (discussed below), it may be useful to interrupt / pull back any oxide layer situated atop the molten metal 100 so that dispersion of the nanoparticles 106 is not hindered by the oxide layer. The nanoparticles 106 may addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com