Optical recording medium

a technology of optical recording medium and optical recording medium, which is applied in the field of optical recording medium, can solve the problems of uncured spin-coating layer near the edge of the center cap that is prone to non-uniformity, and the axial runout of the optical recording medium occurs, and achieves the effect of reducing the axial runout during high-speed rotation and high-reliability recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

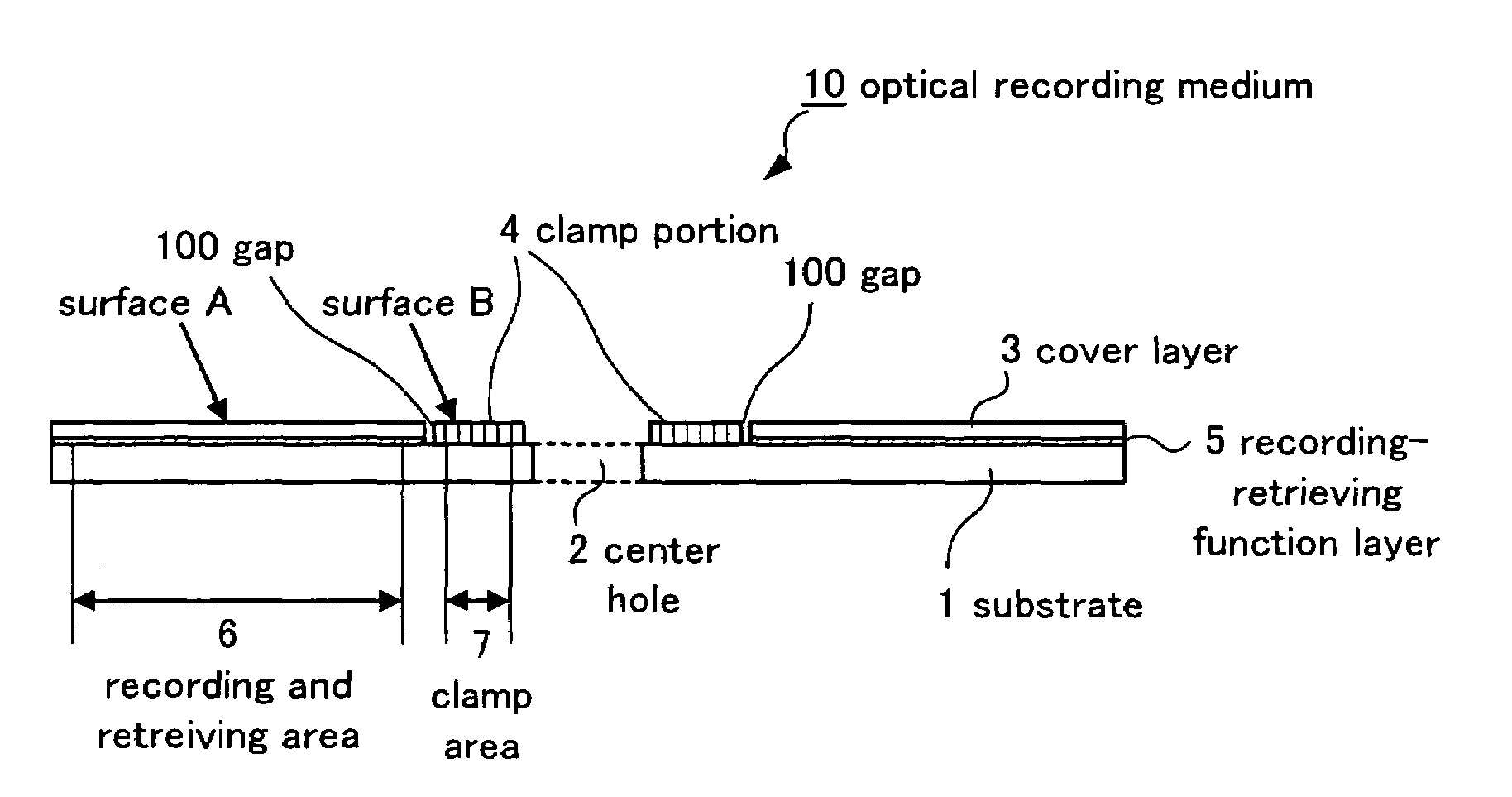

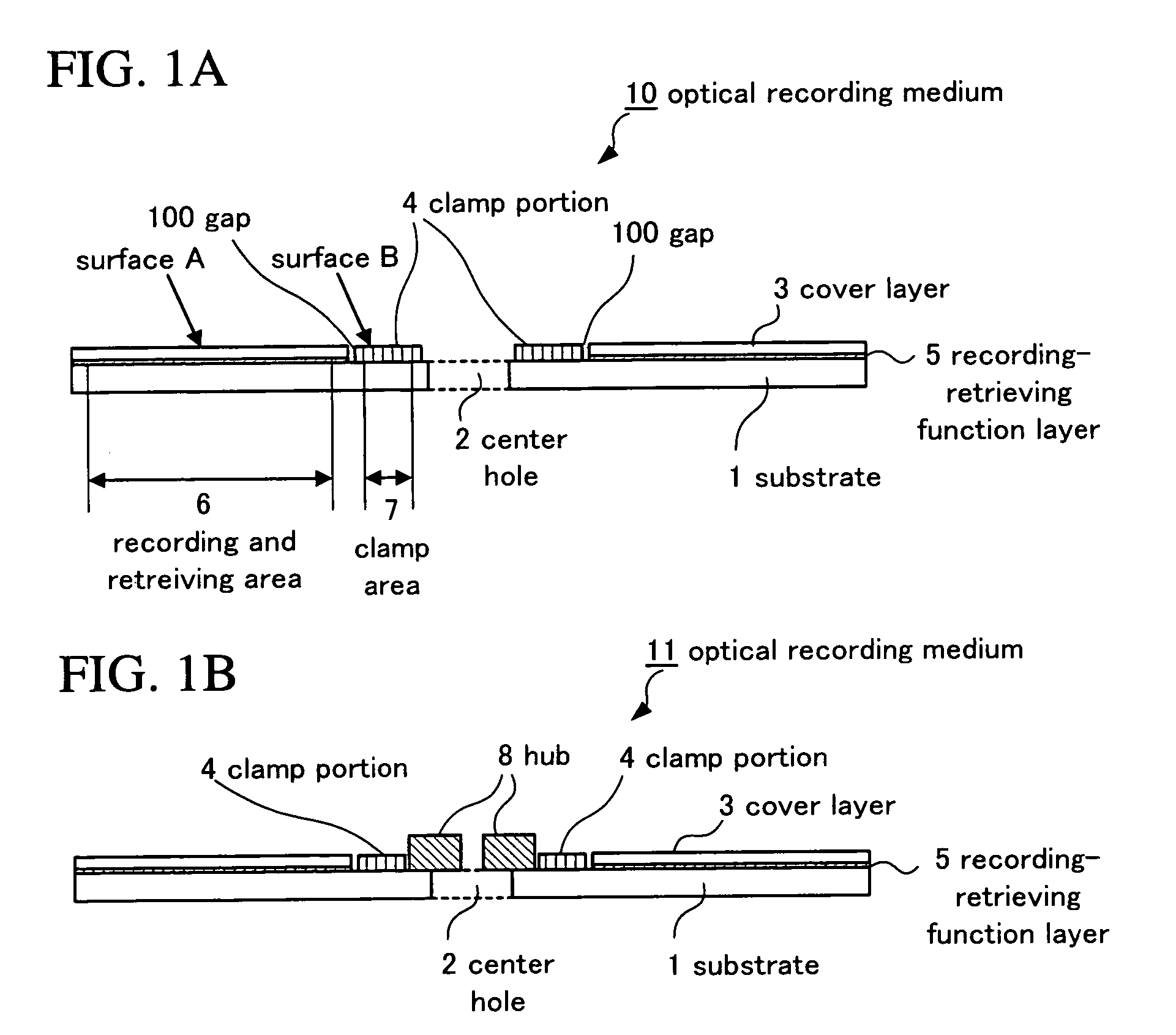

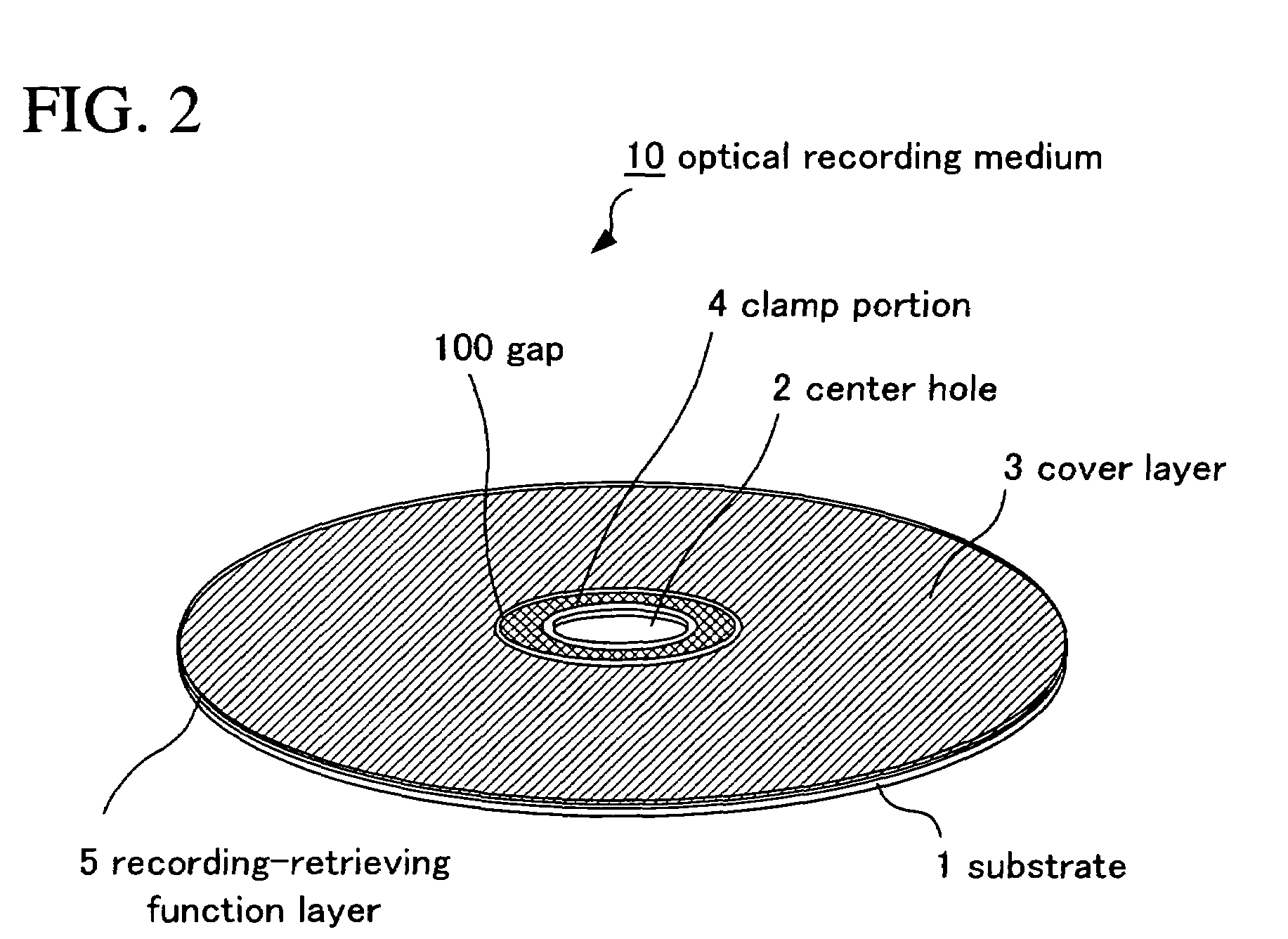

[0106]The optical recording medium 10 in which a clamp portion as separate entity from a cover layer was provided as shown in FIG. 1A was prepared in accordance with the following procedure.

Step of Forming Substrate

[0107]A polycarbonate substrate 1 which had a diameter of 120 mm and a thickness of 1.1 mm and in which a groove for tracking was previously formed at a track pitch of 0.32 μm, was prepared. It is noted that the groove width was approximately 50% of the track pitch, and that the groove depth was 20 to 30 nm.

Step of Forming Recording-Retrieving Function Layer

[0108]Next, a reflecting layer, a dielectric layer 1, a recording layer, and a dielectric layer 2, which are described below, were stacked in this order on the substrate 1 by sputtering to form a recording-retrieving function layer 5, and thus a rewritable optical recording medium was formed.

[0109]Reflecting layer: having a thickness of 100 nm, formed by use of Ag alloy.

[0110]Dielectric layer 1: transparent, having a t...

example 2

[0144]An optical recording medium having a form different from that in the case of Example 1 was prepared in accordance with the following procedure.

[0145]FIG. 8 is a view for explaining a third embodiment of an optical recording medium to which the present embodiment is applied. In FIG. 8, an optical recording medium 800 provided with a clamp portion as a separate entity from a cover layer is shown. The same components as those of the aforementioned optical recording medium 10 shown in FIG. 1A are denoted by the same reference numerals. The optical recording medium 800 comprises: two substrates of a substrate A 204 and a substrate B 205 in which center holes 2 are opened at the respective centers; a recording-retrieving function layer A 200 and a recording-retrieving function layer B 201 which are respectively formed on the substrate A 204 and the substrate B 205 and in which recording and / or retrieving of information signals is performed by use of irradiated light; a cover layer A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| step height | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com