Slotted antenna waveguide plasma source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

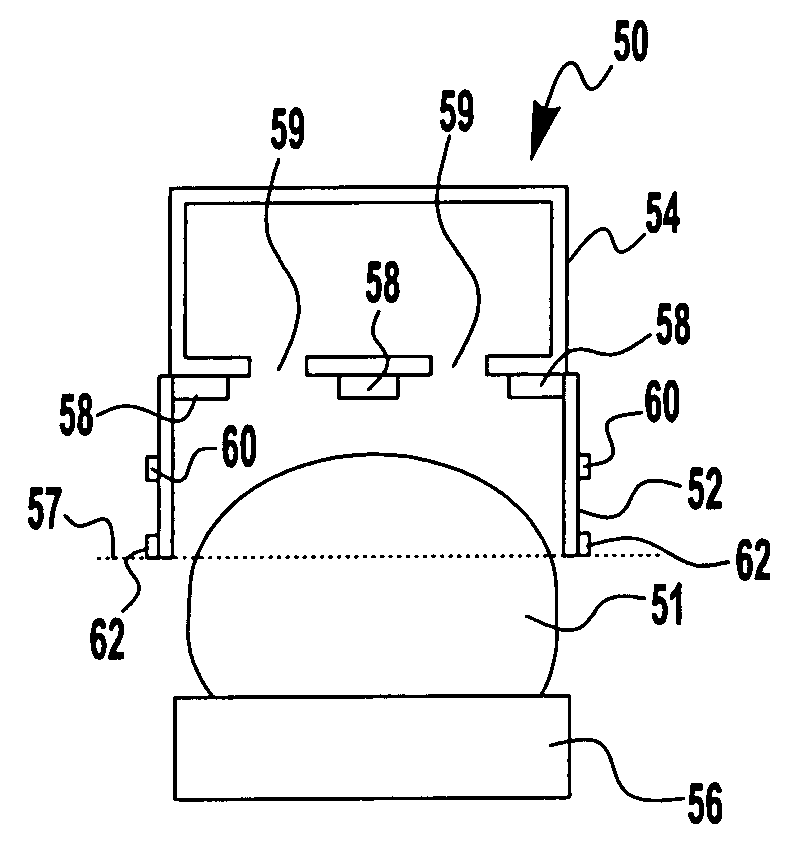

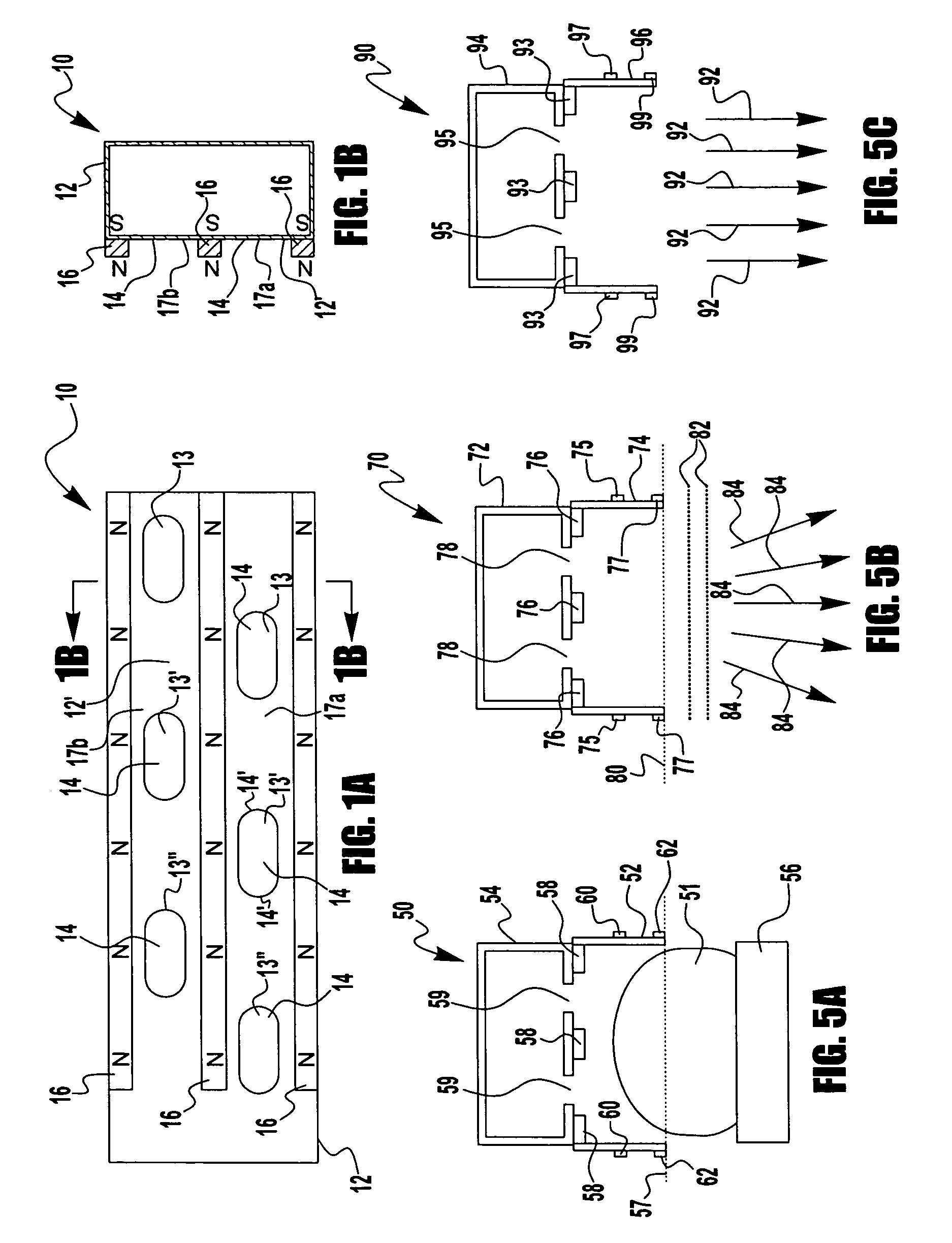

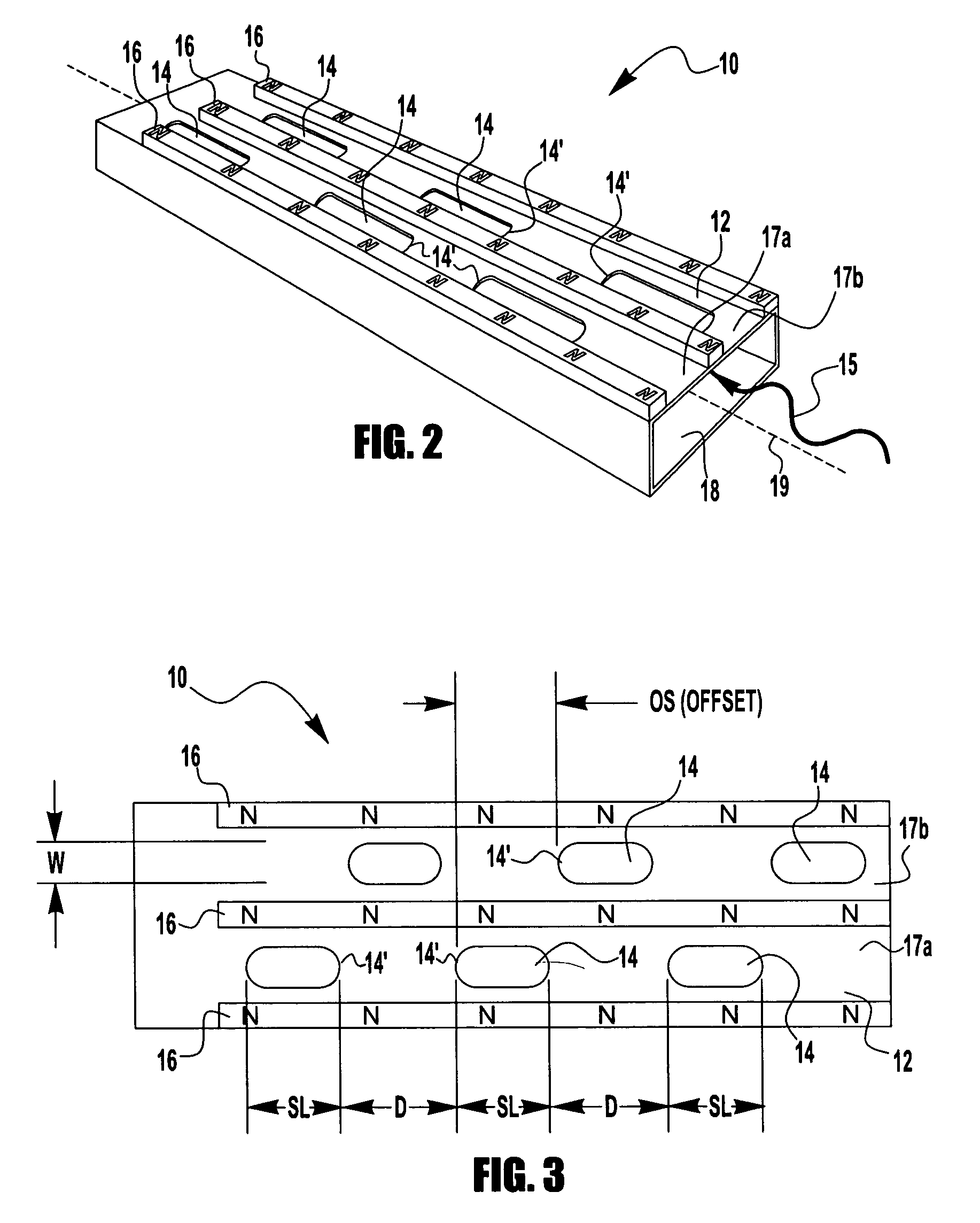

Embodiment Construction

[0041]Electrodeless electron cyclotron resonance (ECR) is the means employed in this slotted antenna waveguide plasma source invention. ECR is a commercially used technology primarily in the fields of high energy research and, at lower power, semiconductor wafer processing equipment for etching and material deposition.

[0042]This present invention has two factors that make it superior to any commercial ECR systems on the market.

[0043]It is electrodeless, and permanent magnets are used to generate the plasma as opposed to present-day commercial systems that use electromagnets and electrodes that are consumable. In wafer processing the electrode slowly erodes and results in some level of contamination on the wafer surface. Contaminated wafer areas are waste, thereby reducing processing throughput, efficiency, and yield. The technology eliminates the electrode and the subsequent contamination resulting in improved processing.

[0044]The configuration of the magnets above the slotted grid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com