Support and grounding structure

a technology of supporting and grounding, applied in the direction of coupling device connection, electrical apparatus construction details, coupling device details, etc., can solve the problem of workers who are expected to be subjected to vigorous or rough handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Embodiments and examples are described hereafter by way of example only in the following with reference to the accompanying drawings.

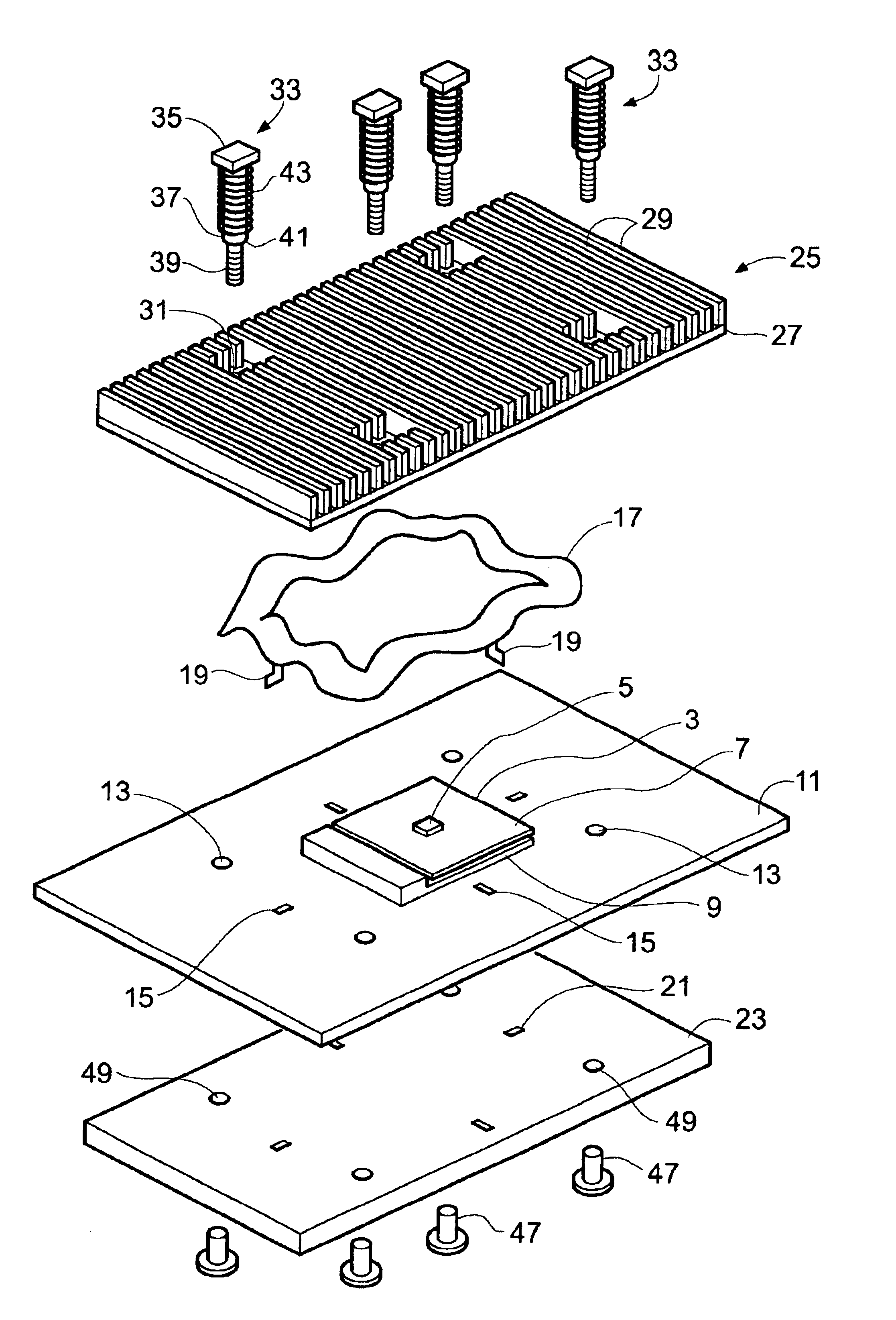

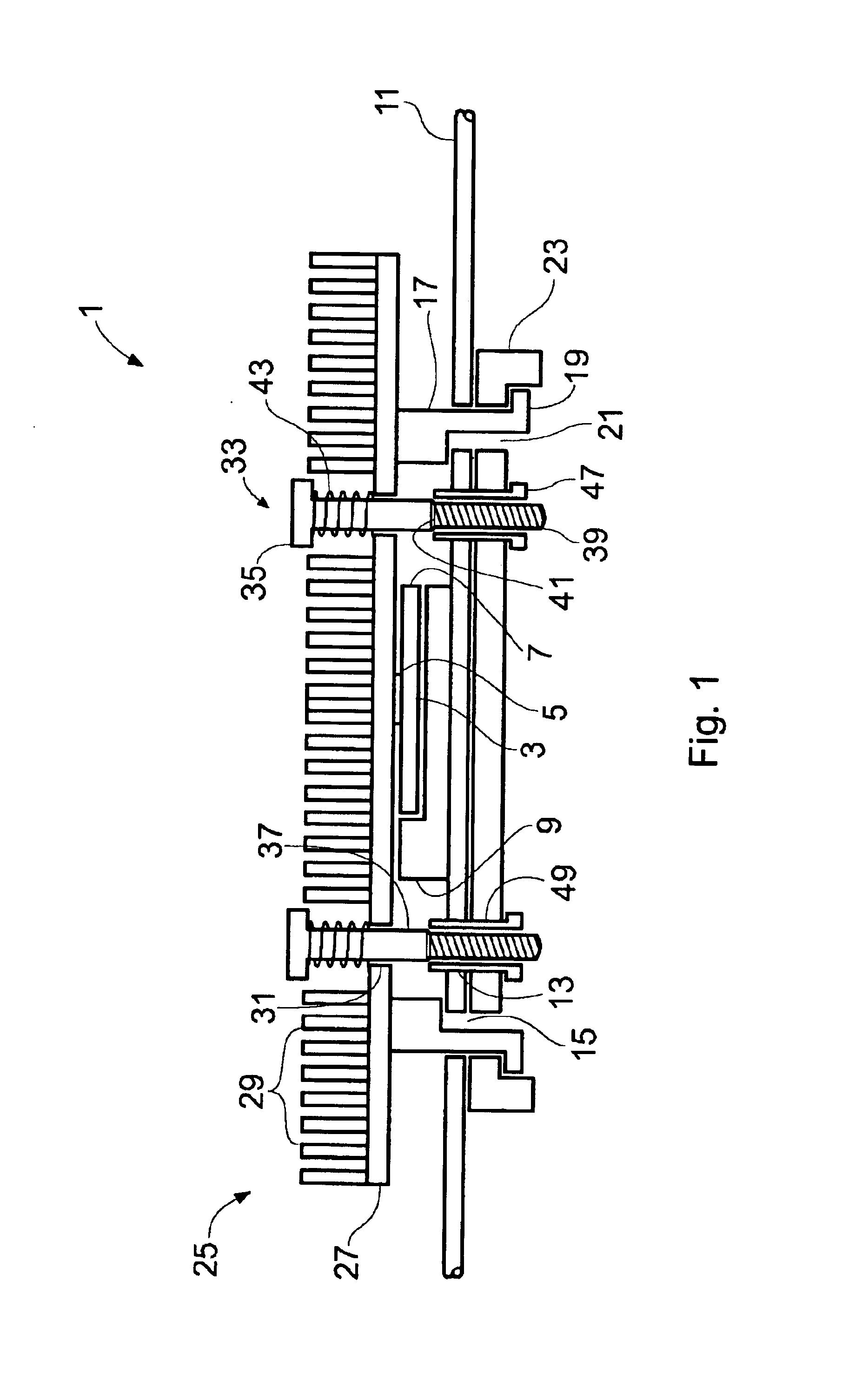

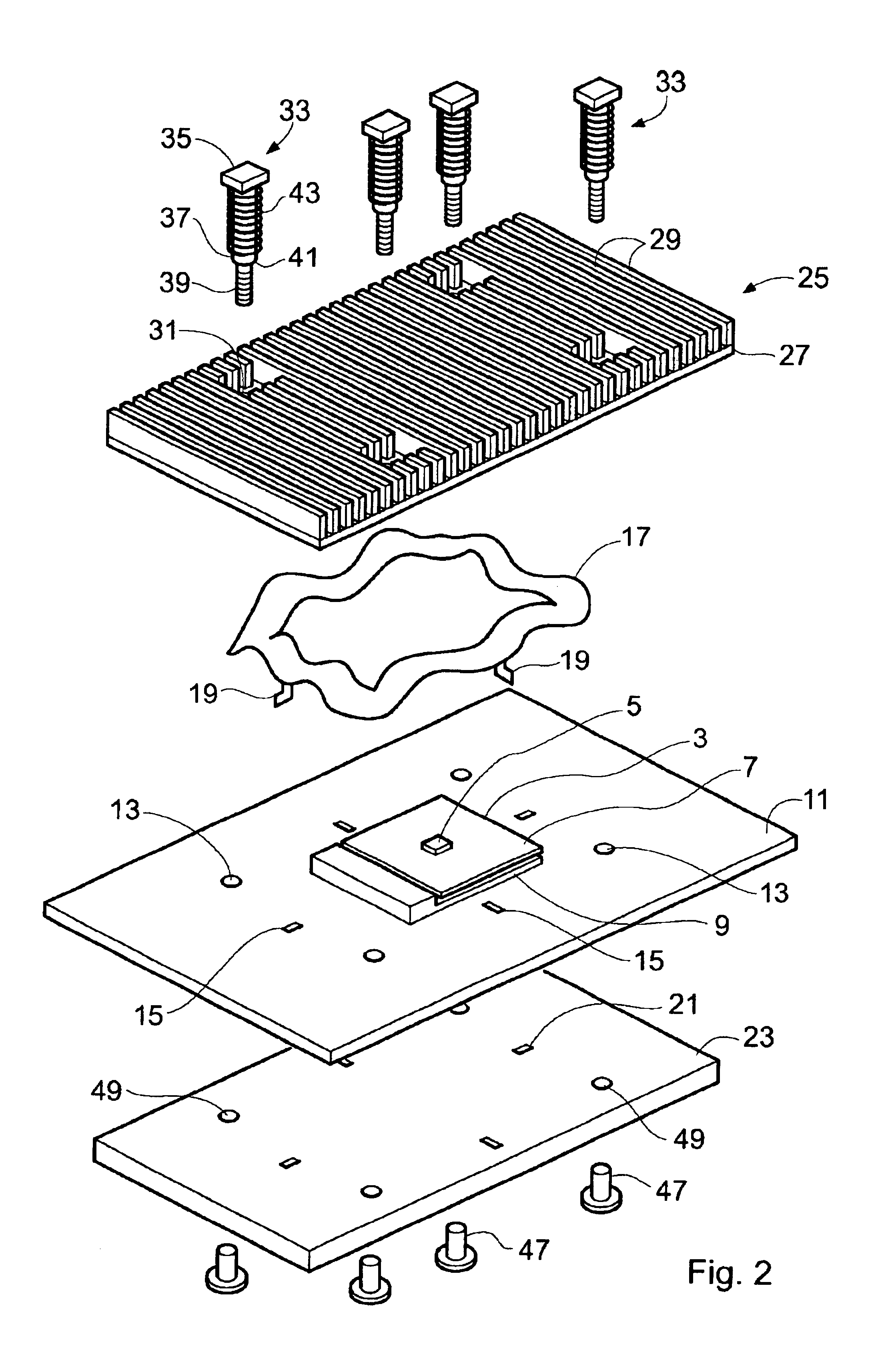

[0019]Shown in FIG. 1 is a schematic cross section view of a support and grounding structure 1 according to a first example. FIG. 2 shows the support and grounding structure of FIG. 1 from an exploded perspective viewpoint. FIG. 3 shows part of the support and grounding structure of FIG. 1 from an assembled perspective viewpoint. FIG. 4a shows a plan view of a shielding member of the support and grounding structure of FIG. 1 and FIGS. 4b and 4c show sections through the shielding member of FIG. 4a take through lines I—I and II—II respectively.

[0020]The grounding and support structure 1 is provided for a processor 3. The processor 3 of the present example has an exposed processor die 5 mounted onto a substrate 7. Examples of processors having this type of design include Celeron series processors manufactured by Intel Corporation and Athlon™ and Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com