Modified diffusion layer for use in a fuel cell system

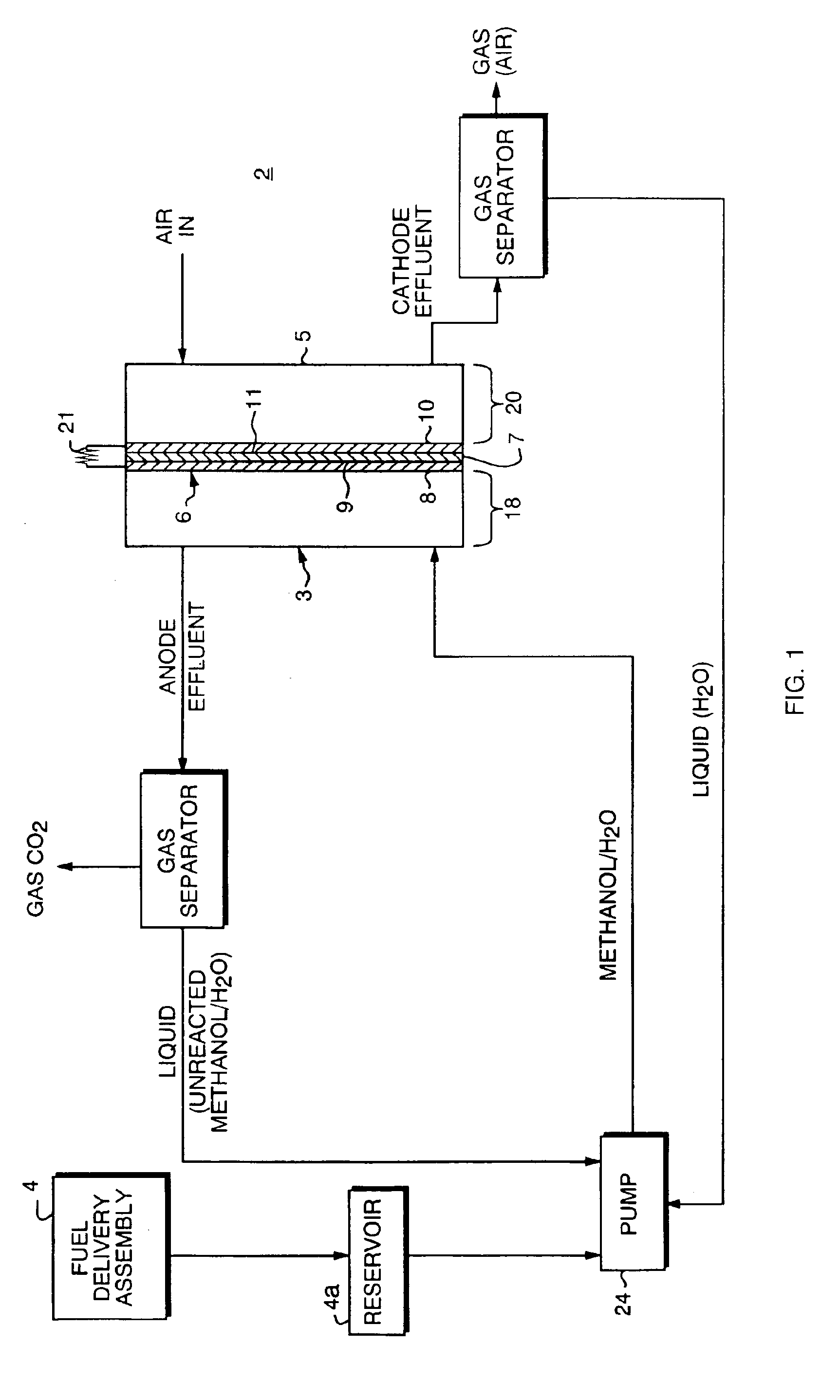

a fuel cell and diffusion layer technology, applied in cell components, electrochemical generators, transportation and packaging, etc., to achieve the effect of enhancing the cell performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

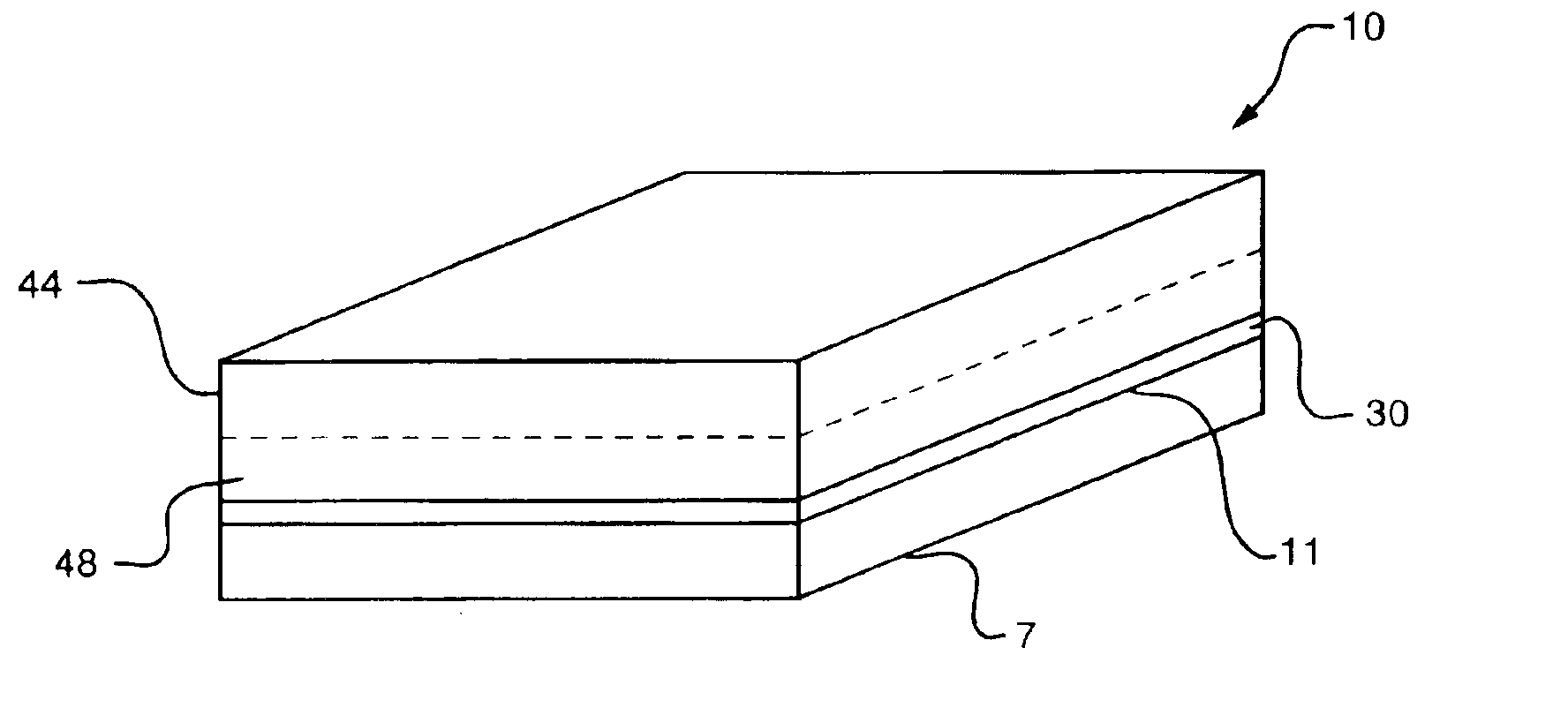

Image

Examples

example

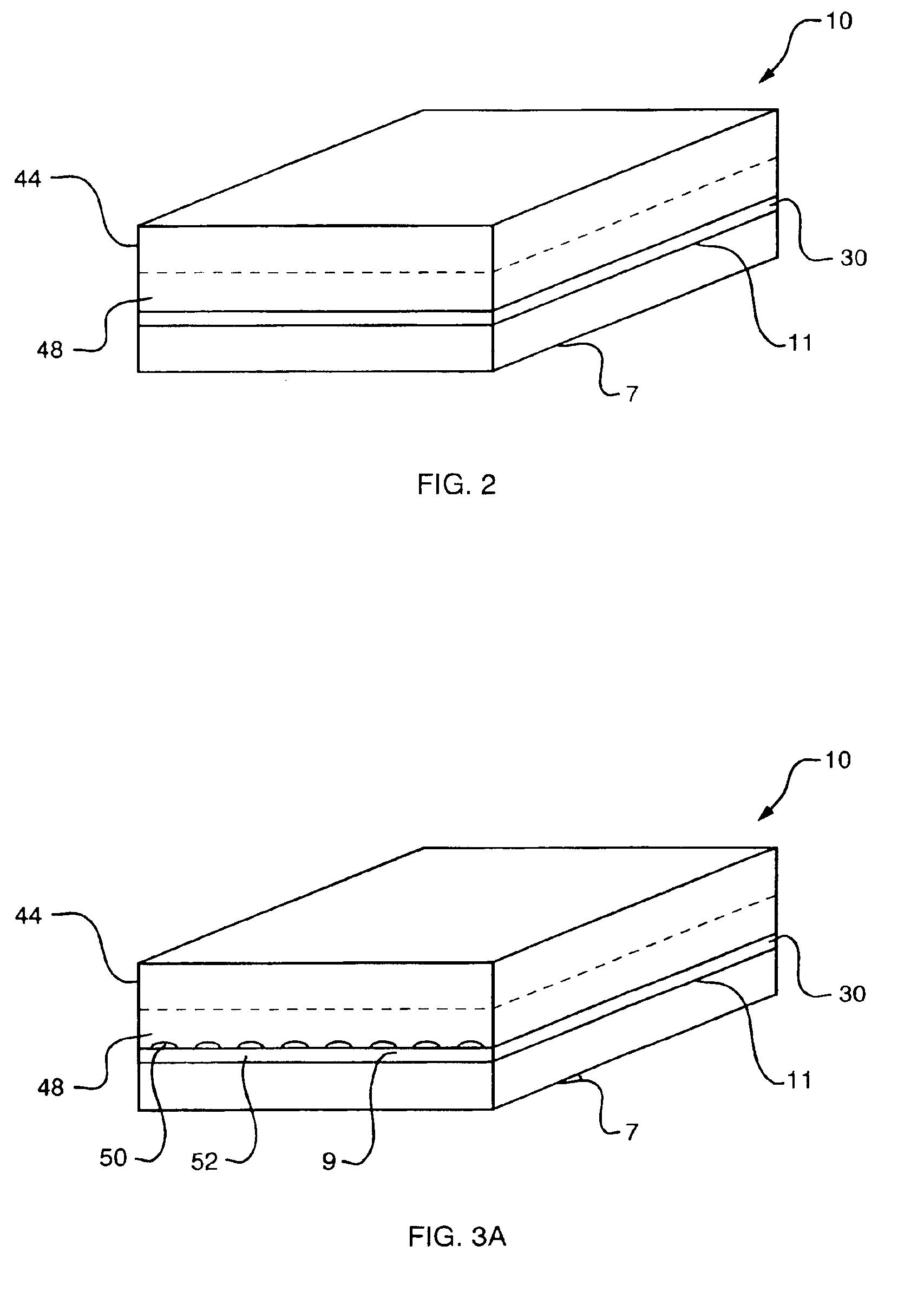

[0044]A diffusion layer was fabricated by employing a substrate formed from a sheet of ELAT diffusion backing, commercially available from the E-Tek division of De Nora N.A., 39 Veronica Avenue, Somerset, N.J. 08873, measuring about 3.162 cm by 3.162 cm. This diffusion layer was comprised of a carbon cloth substrate with a microporous layer comprised of Teflon-bonded high surface area carbon particles. A lattice like pattern was embossed into the diffusion layer using pressure of 10,000 pounds per square inch, the pattern extending to the edges of the diffusion layer. The embossed diffusion layer was then placed in intimate contact with a catalyst coated membrane for use in the membrane electrode assembly of a direct methanol fuel cell.

[0045]The microporous layer tends to form a hydrophobic barrier adjacent the catalyst coated PCM, however, water can still build up near the cathode face of the fuel cell. The embossment in the cathode diffusion layer causes such water to travel along...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| protonically conductive | aaaaa | aaaaa |

| electrically conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com