A2 Clip for Side-Delivered Transcatheter Mitral Valve Prosthesis

a prosthetic and mitral valve technology, applied in the field of a2 clip for a side-delivered prosthetic mitral valve, can solve the problems of allowing some regurgitation, affecting the repair effect, and not fully correcting the valve problem, so as to achieve the effect of reducing the strain of wire cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

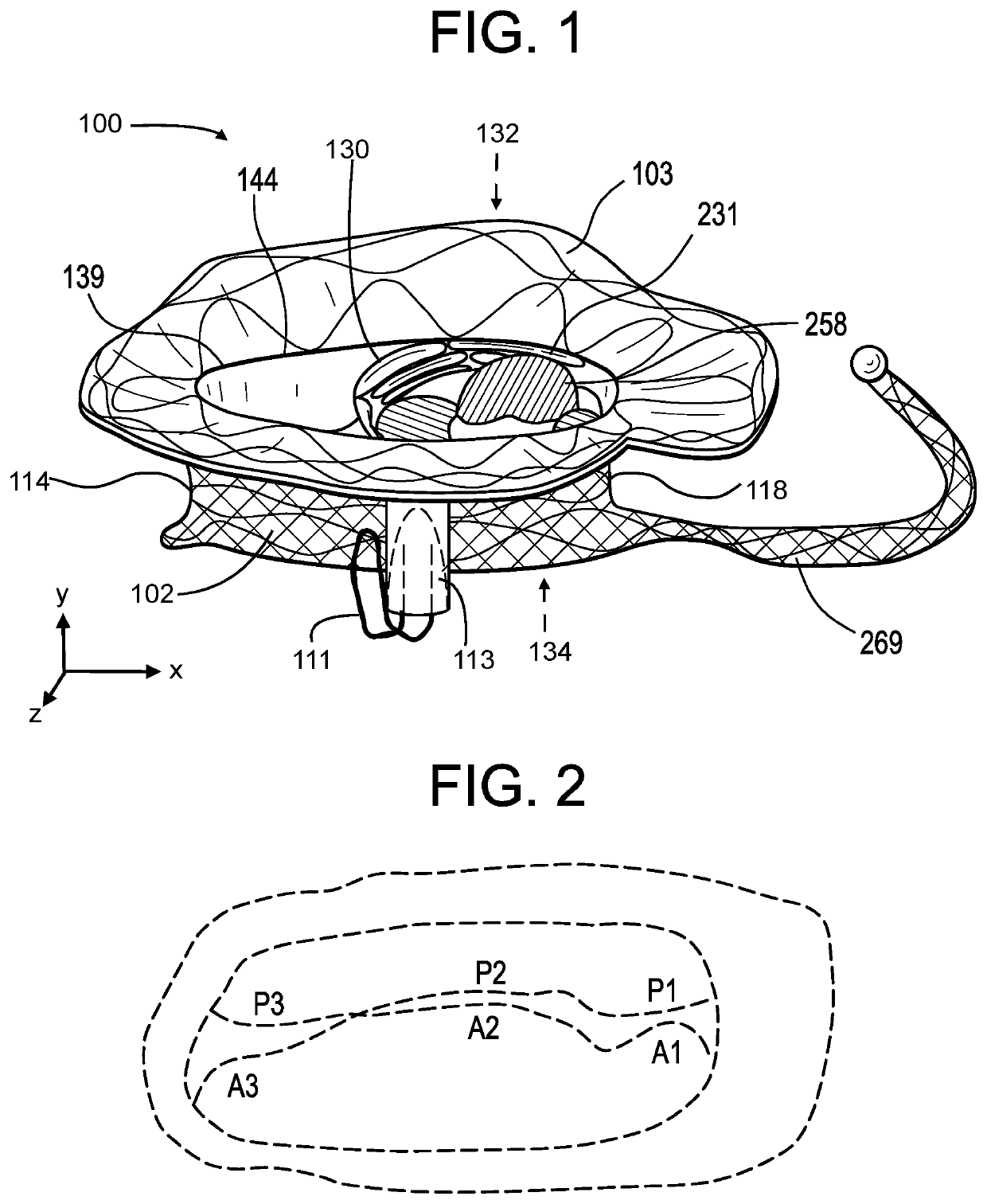

[0176]The transcatheter prosthetic heart valve may be percutaneously delivered using a transcatheter process via the femoral through the IVC, carotid, sub-xyphoid, intercostal access across the chest wall, and trans-septal to the mitral annulus through the fossa ovalis.

[0177]The device is delivered via catheter to the right or left atrium and is expanded from a compressed shape that fits with the internal diameter of the catheter lumen. The compressed valve is loaded external to the patient into the delivery catheter, and is then pushed out of the catheter when the capsule arrives to the atrium. The cardiac treatment technician visualizes this delivery using available imaging techniques such as fluoroscopy or ultrasound.

[0178]In a preferred embodiment the valve self-expands upon release from the catheter since it is constructed in part from shape-memory material, such as Nitinol®, a nickel-titanium alloy, or a cobalt-chromium alloy, alloys used in biomedical implants.

[0179]In anothe...

example — manufacturing process

Example—Manufacturing Process

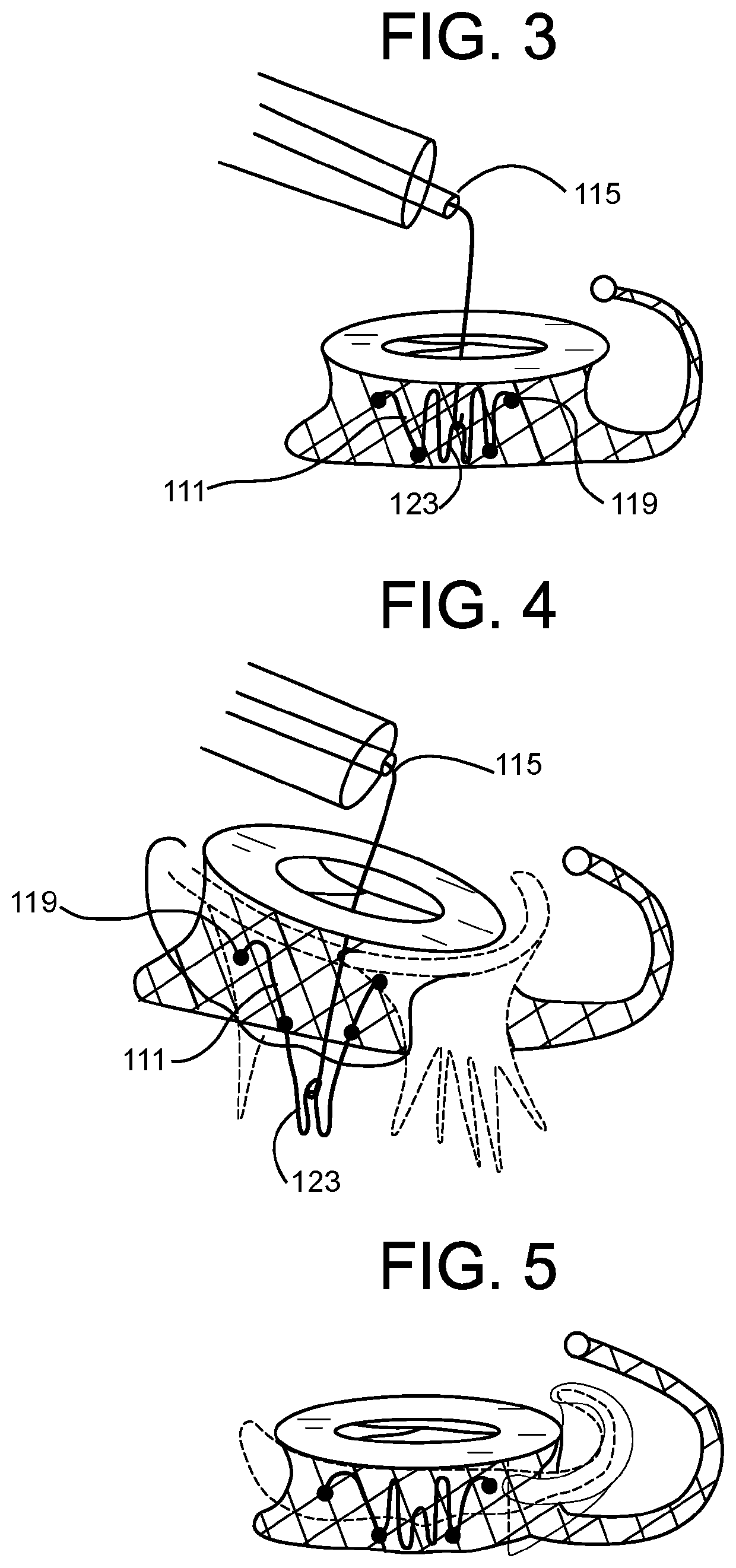

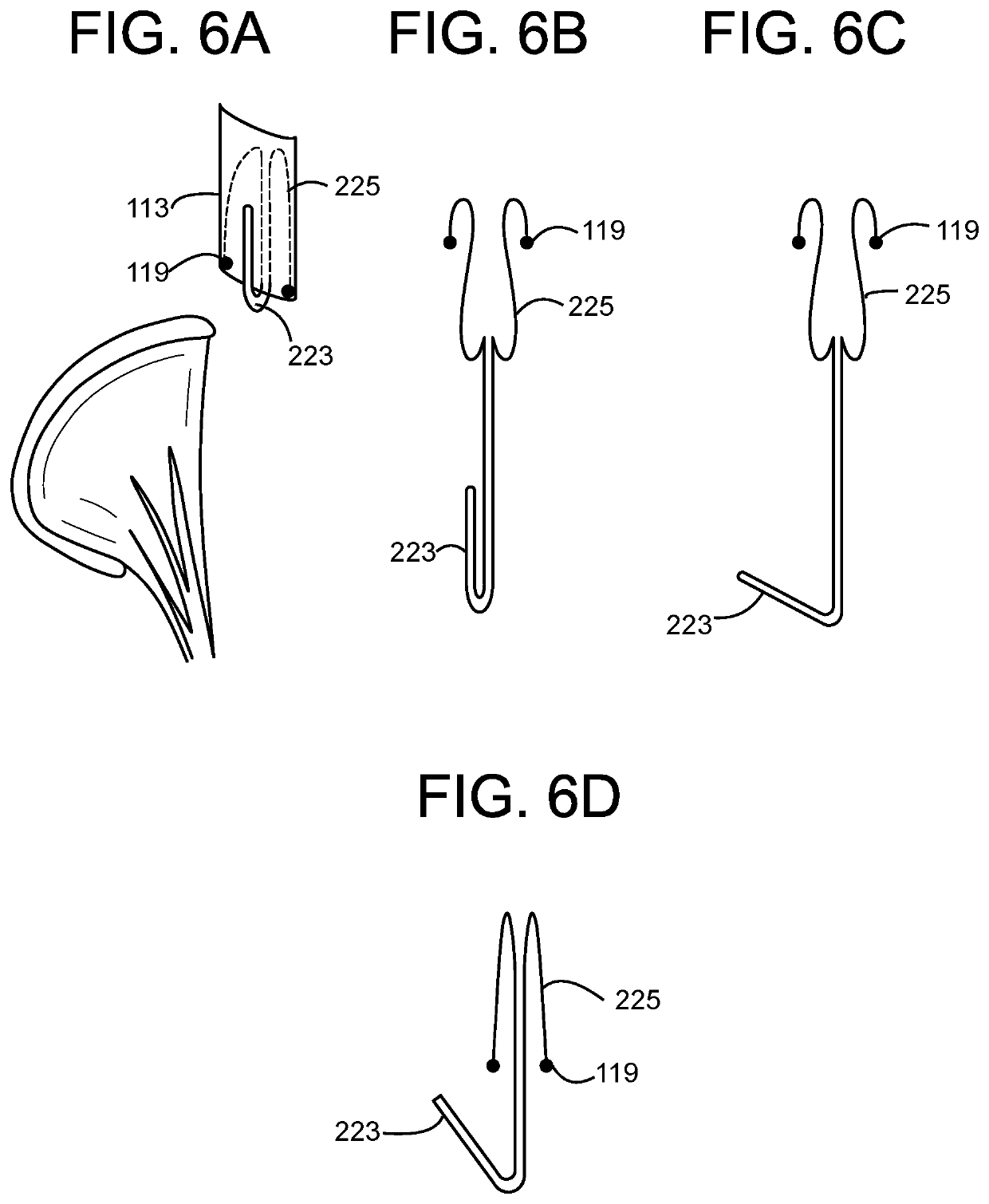

[0181]In a preferred embodiment the invention includes a process for manufacturing a side-delivered transcatheter prosthetic heart valve frame, comprising:[0182](i) using additive or subtractive metal or metal-alloy manufacturing to produce[0183]a self-expanding annular support frame,[0184]wherein the additive metal or metal-alloy manufacturing is 3D printing or direct metal laser sintering (powder melt), and[0185]wherein the subtractive metal or metal-alloy manufacturing is photolithography, laser sintering / cutting, CNC machining, electrical discharge machining.

[0186]In another preferred embodiment, there is provided a process for manufacturing a side-delivered transcatheter prosthetic heart valve frame, further comprising the steps of: (ii) mounting a flow control component within the valve frame, said flow control component configured to permit blood flow along the central vertical axis through an inflow end of the flow control component and block blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com