Method for creating branch seam with temporary plugging and pressure buildup using super absorbent resin

a super absorbent resin and branch seam technology, applied in fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problems of low fracturing efficiency, difficult to extrude complex multi-level fracture networks, and hot issue of unconventional oil and gas resources, etc., to increase the production of oil, increase the fracture network area, and strengthen the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0028]A method for creating a branch fracture with temporary plugging and pressure buildup using super absorbent resin, comprises the following steps:

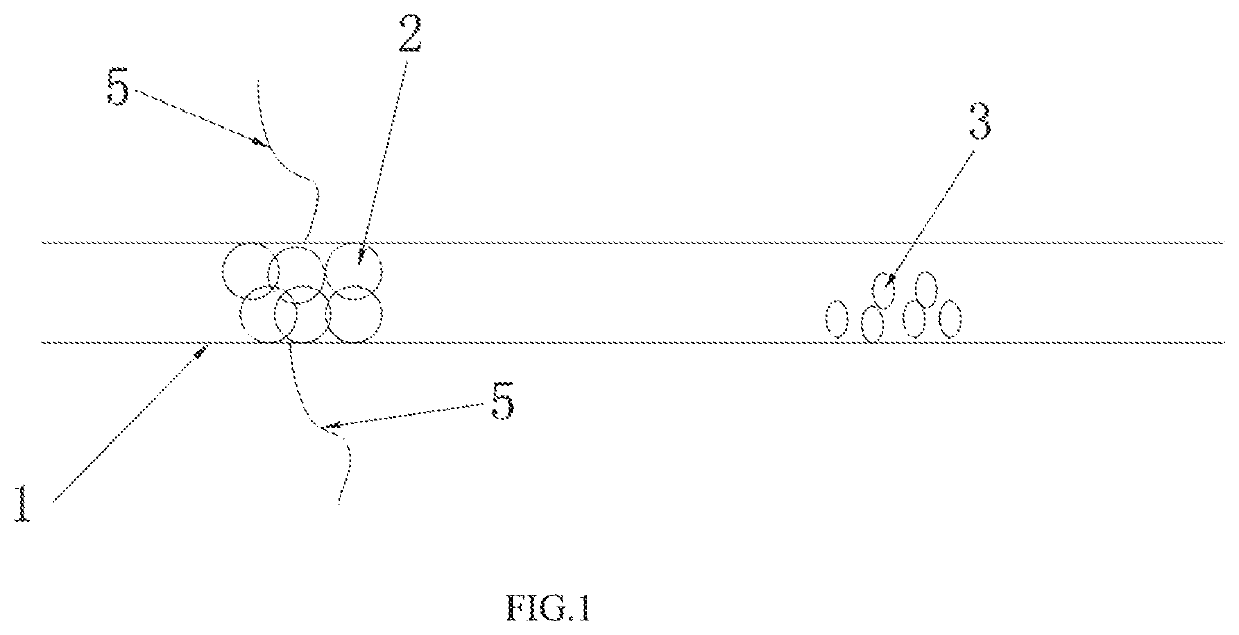

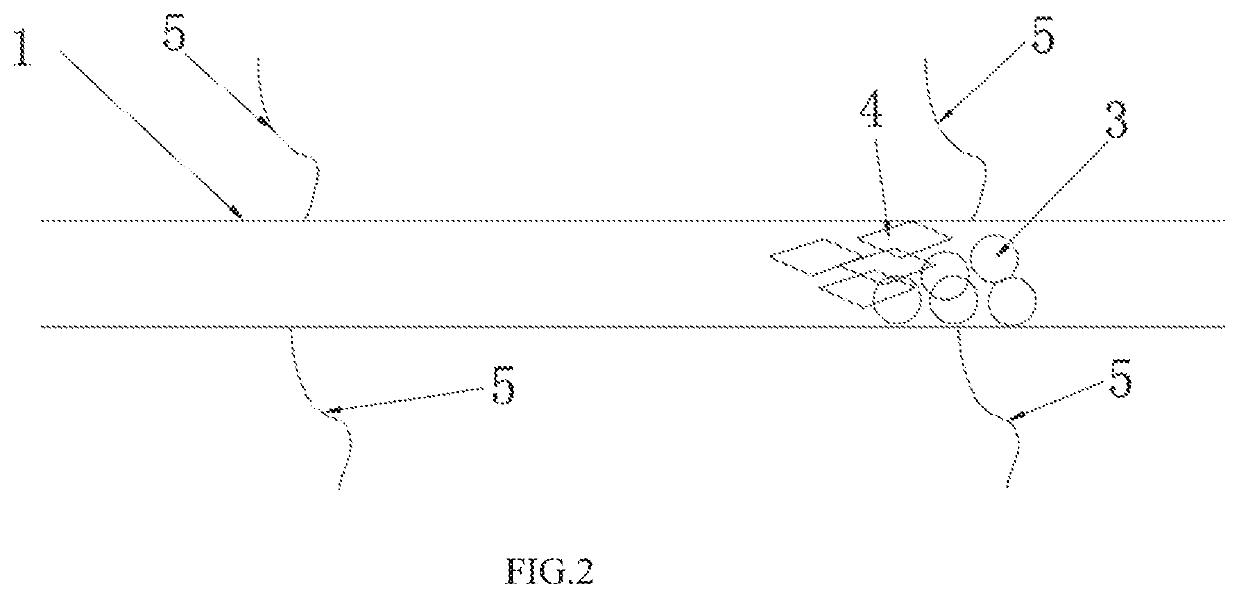

[0029]Step 1: setting a fracturing packer, injecting pad fluid of 45 m3, and using the pad fluid to fracture a target layer to form a main fracture 1;

[0030]Step 2: selecting starch graft polyacrylamide with a particle size of 0.7 mm, a water absorption ratio of 45 g / g, and a compression strength per cubic centimeter in saturated brine of 0.06 MPa-1 MPa as salt-intolerant super absorbent resin 3; selecting a ternary copolymerized salt-tolerant acrylic acid super absorbent resin with a particle size of 0.5 mm, a water absorption ratio of 175 g / g, and a compression strength per cubic centimeter in saturated brine of 0.02 MPa as strong salt-tolerant super absorbent resin 2; continuously injecting pad fluid of 7 m3 mixed with salt-intolerant super absorbent resin 3 into the main fracture 1 at a speed of 4.5 m3 / min; then injecting pad fluid ...

embodiment 2

[0036]A method for creating a branch fracture with temporary plugging and pressure buildup using super absorbent resin, comprises the following steps.

[0037]Step 1: setting a fracturing packer, injecting pad fluid of 37 m3, and using the pad fluid to fracture a target layer to form a main fracture 1;

[0038]Step 2: selecting cellulose grafted polyacrylamide with a particle size of 1.5 mm, a water absorption ratio of 75 g / g, and a compression strength per cubic centimeter in saturated brine of 1.2 MPa as salt-intolerant super absorbent resin 3; selecting a ternary copolymerized salt-tolerant acrylic acid super absorbent resin with a particle size of 1.2 mm, a water absorption ratio of 245 g / g, and a compression strength per cubic centimeter in saturated brine of 0.05 MPa as strong salt-tolerant super absorbent resin 2; first continuously injecting pad fluid of 6 m3 mixed with salt-intolerant super absorbent resin 3 into the main fracture 1 at a speed of 5.5 m3 / min; then injecting pad fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com