Panel polishing apparatuses and a panel polishing method

a technology for polishing apparatuses and panels, applied in the direction of grinding feeders, grinding machine components, manufacturing tools, etc., can solve the problems of bottlenecks affecting the production efficiency of panels, low work efficiency, and risk of blocking, so as to improve the polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In order to make the purpose, technical solutions and advantages of the present invention more comprehensible, the present invention is further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, and are not intended to limit the present invention.

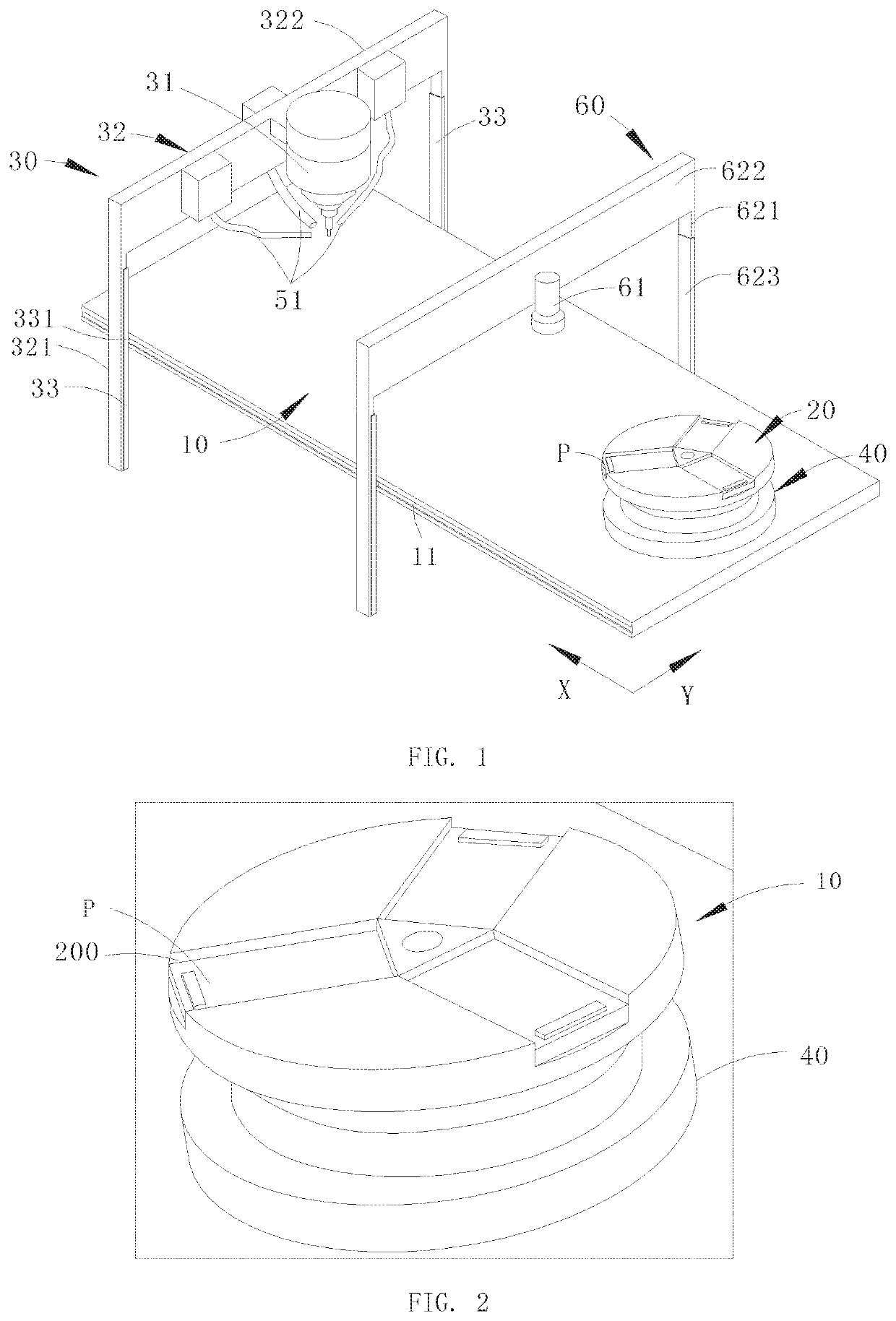

[0028]Referring to FIG. 1 and FIG. 2, the polishing apparatus for a panel in the present embodiment comprises a carrier 10, a disk 20 which is rotatably arranged on a top surface of the carrier 10, and a polishing mechanism 30. A plurality of trenches 200 are located on the disk for placing the panel P, and the polishing mechanism 30 is used for polishing the panel P disposed in the trench 200.

[0029]As shown in FIG. 3, as an exemplary driving manner, a rotation motor 40 is fixed on the carrier 10 in the present embodiment. A base of the rotation motor 40 is fixed on the carrier 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com