High Speed Handling of Ultra-Small Chips by Selective Laser Bonding and Debonding

a laser bonding and debonding technology, applied in metal working equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the throughput and cost performance of the fan-out package, requiring hundreds of hours to get a reconstituted 12-inch wafer via pick-and-place processing, and affecting the speed of the process. , to achieve the effect of high speed handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

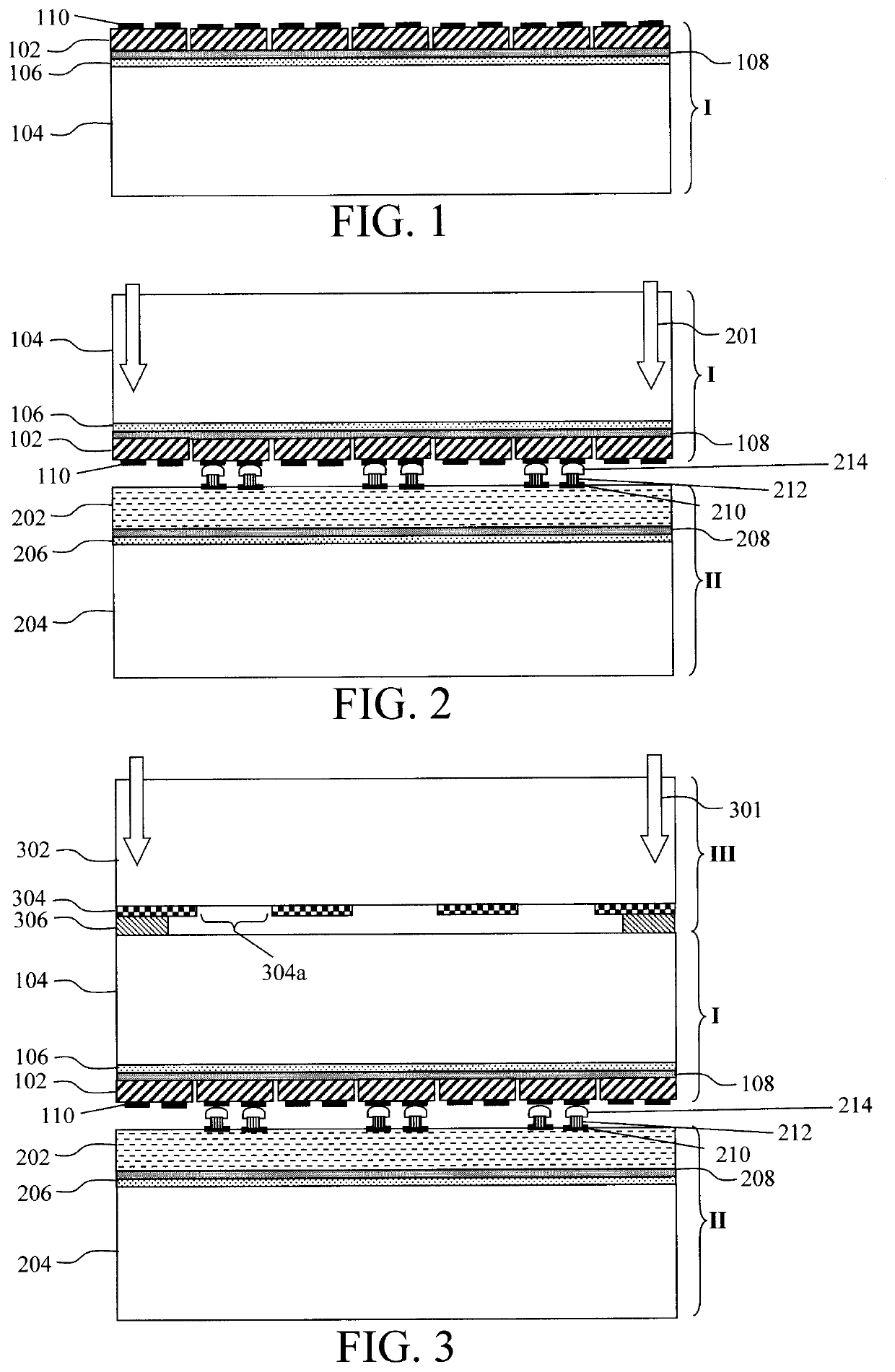

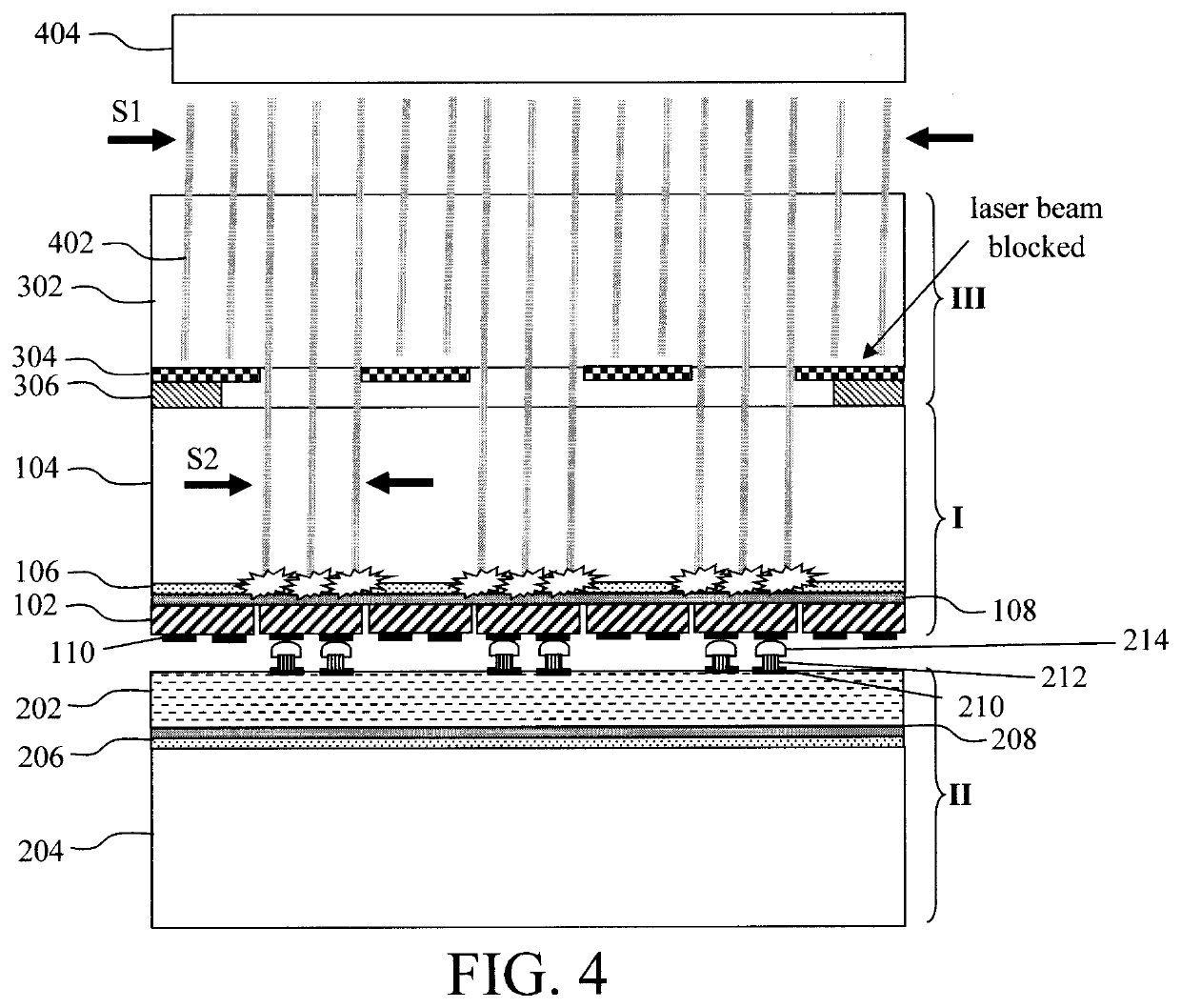

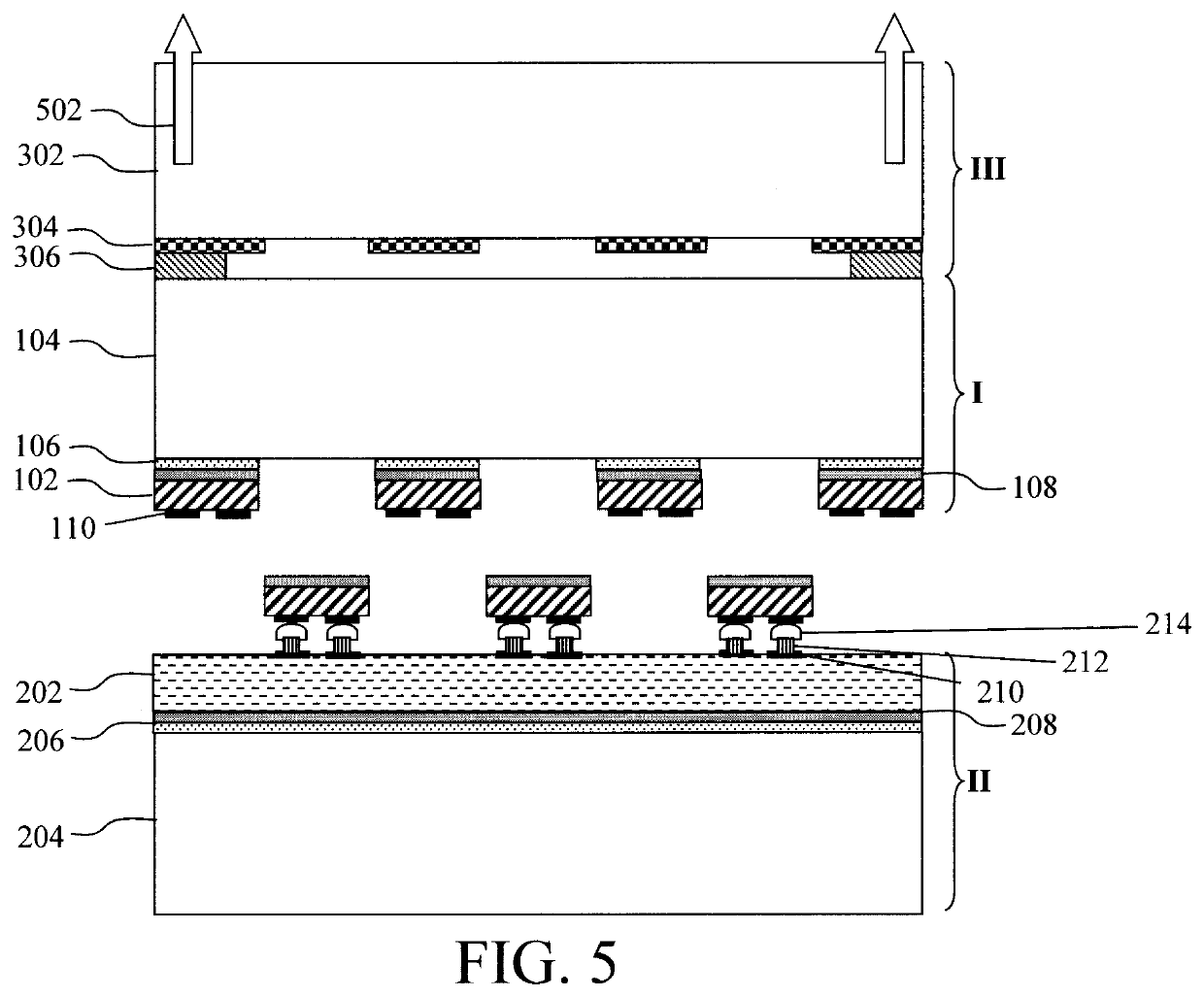

[0032]Provided herein are techniques for high-speed precision handling of micro-chips for fan-out wafer-level packaging (FOWLP) and other heterogeneous integration applications. The term “micro-chip,” as used herein, refers to a chip with a substrate that is less than 100 micrometers (μm)×100 μm. For instance, radio-frequency identification (RFID) chips typically have substrate dimensions of about 40 μm×40 μm, and light-emitting diode (LED) chips typically have substrate dimensions of about 8 μm×8 μm. Thus, RFID and LED chips are considered herein to be micro-chips.

[0033]As will be described in detail below, the present techniques employ a precise laser and optical guide system to selectively place micro-chips on a thin, flexible substrate from a handle wafer. In one exemplary embodiment, a template wafer is employed to focus a (large spot size) laser beam precisely onto specific locations on the handle wafer to release single micro-chips from the handle wafer. In another exemplary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spot size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com