Hardfacing Material

a hardfacing material and alloy technology, applied in the field of alloy materials, can solve the problems of limited development and application of hardfacing alloys, workpieces coated with different surface modification layers made of various conventional hardfacing materials are unable to meet the requirements of the environment implemented with workpieces, etc., to achieve outstanding functional performance, long service life, and superior characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

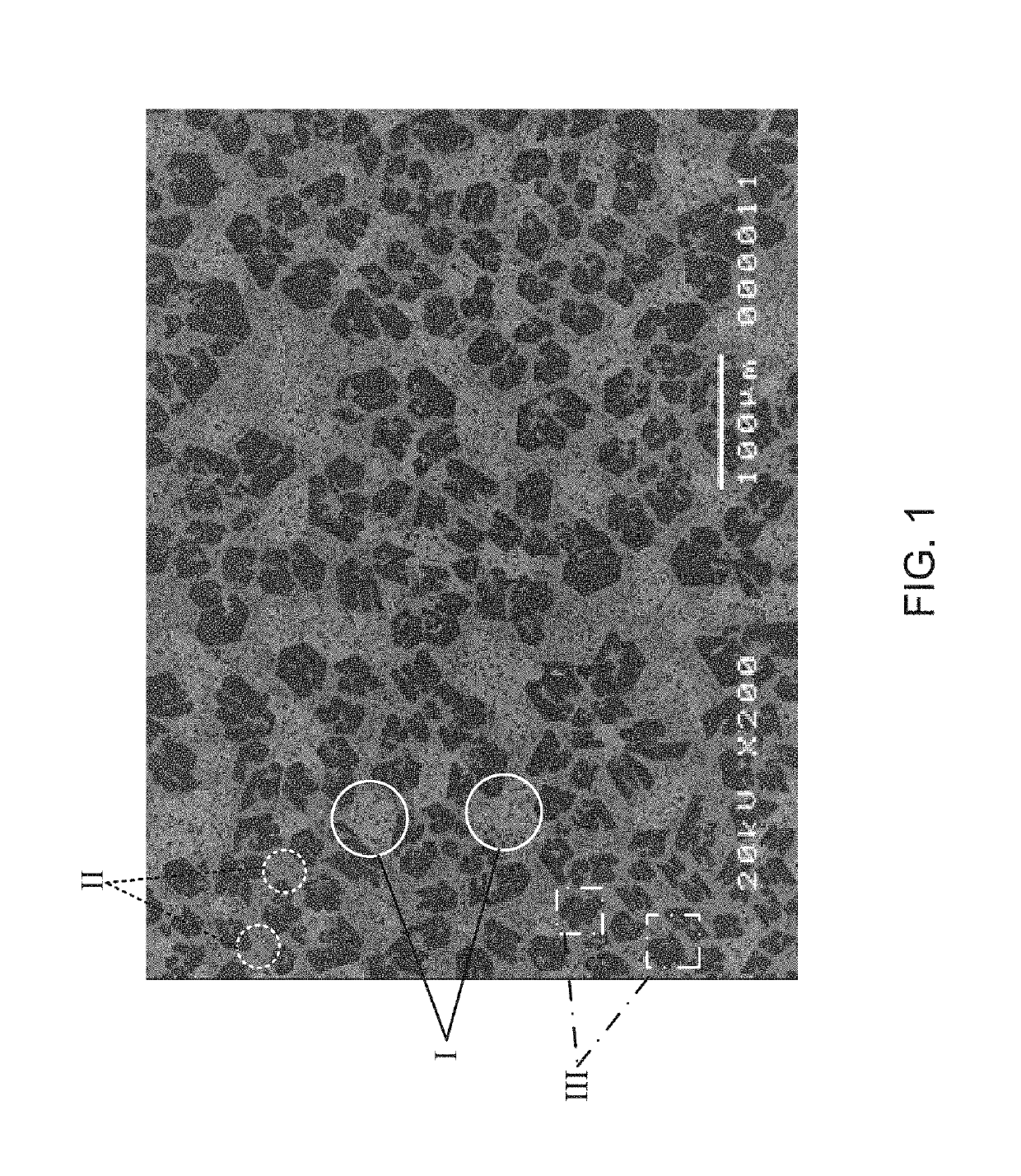

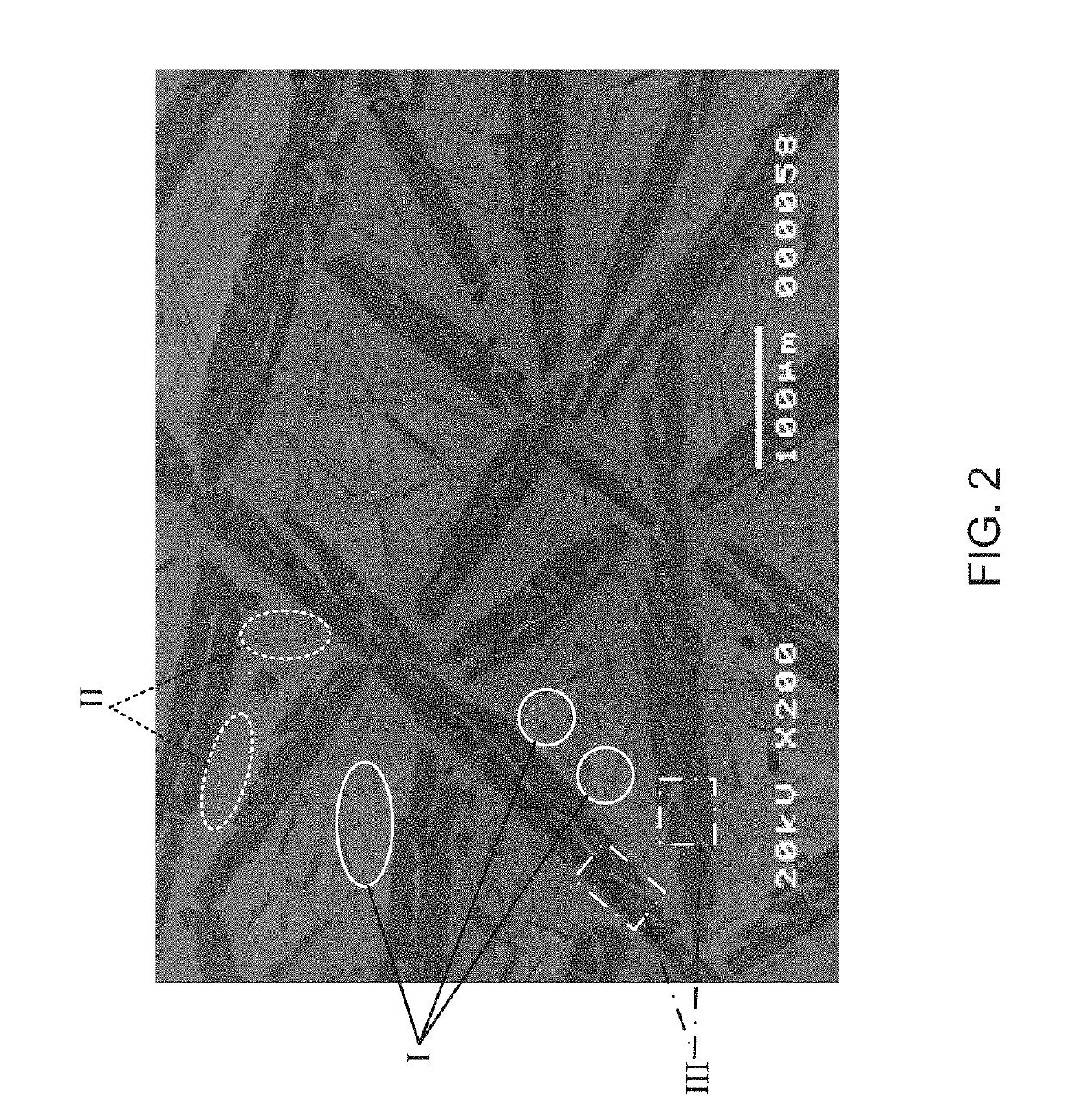

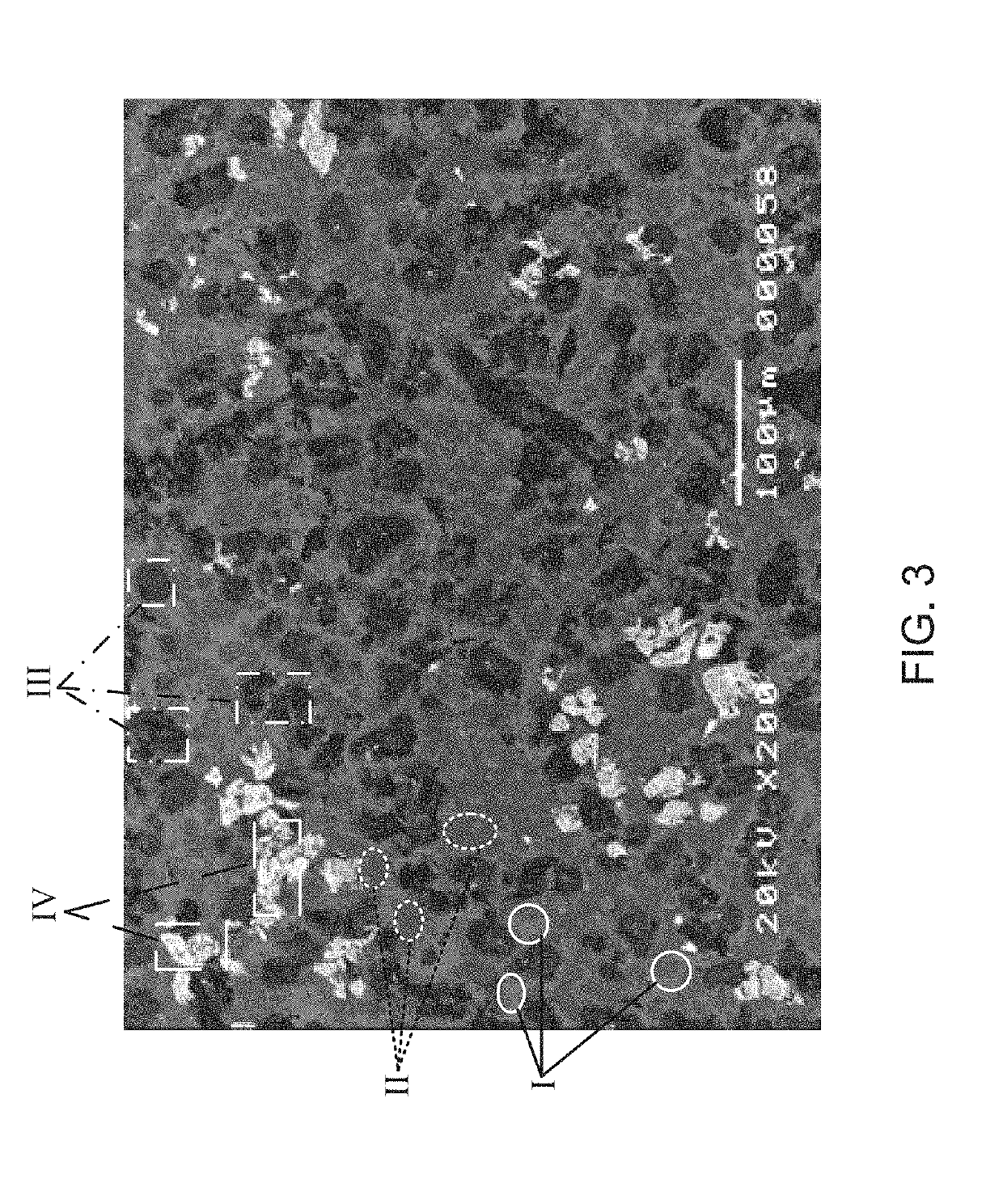

[0021]To more clearly describe a hardfacing material according to the present invention, embodiments of the present invention will be described in detail with reference to the attached drawings hereinafter.

[0022]Traditional hardfacing alloys often contain one kind of primary elemental composition; for example, Fe-based, Co-based or Ni-based hardfacing alloy containing with other additional elements such as Cr, V, and / or Mo for enhancing corrosion resistance and thermal stability thereof. Particularly, the present invention discloses a hardfacing material comprises at least four principal metal elements at least four principal metal elements and at least one non-metal element, wherein the principal metal elements and the at least one non-metal element form at least one base alloy structure and at least one precipitation-strengthened alloy structure of the hardfacing material. It needs to further explain that, at least four principal metal elements are selected from the group consisti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| structure | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| corrosion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com