Method to mitigate fouling of a vacuum wash bed

a technology of vacuum wash bed and wash bed, which is applied in the direction of vacuum distillation, hydrocarbon oil treatment, corrosion/fouling inhibition of treatment apparatus, etc., to achieve the effects of preventing thermoset, reducing injection rate, and preventing the buildup of soft-solid or viscous polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

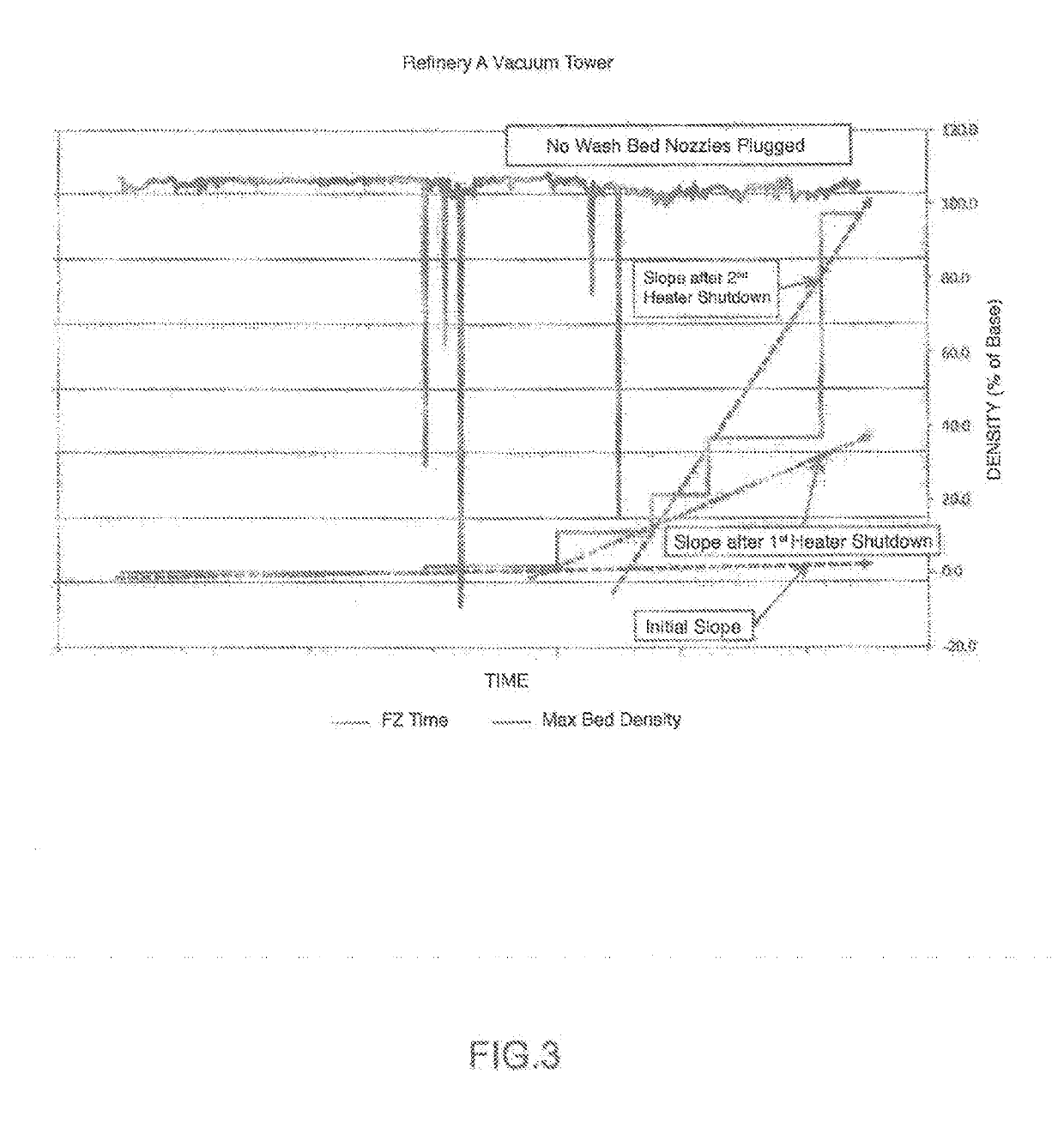

[0018]The cooling of the vacuum tower wash bed below 350° F. causes a thermoset polymer to form, which then cannot be removed except by mechanical means. An injection of a solvent such as LCO before the temperature of the wash drops below 350° F. removes the polymer before it hardens.

[0019]The LCO contains petroleum distillates. In one embodiment, the LCO is a complex mixture of paraffinic, cycloparaffinic, olefinic and aromatic hydrocarbons. The LCO is predominately C9-C25 hydrocarbons produced by the distillation of products from a catalytic cracking process. This stream is likely to contain a relatively large portion of bicyclical aromatic hydrocarbons.

[0020]In another embodiment, the fluid medium may be an FCC slurry or decanted oil. Typically, the FCC slurry consists of aromatic hydrocarbons from FCC slurry oil processing technologies including hydrotreating, solvent refining and other separation techniques. Decanted oil may be a fluid catalytic cracker decanted oil, a heavy cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com