Industrial building construction process

a construction process and industrial building technology, applied in the field of civil construction, can solve the problems of large amount of material used in construction, large loss of handling, and time-consuming activities, and achieve the effect of convenient, fast, clean and sa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

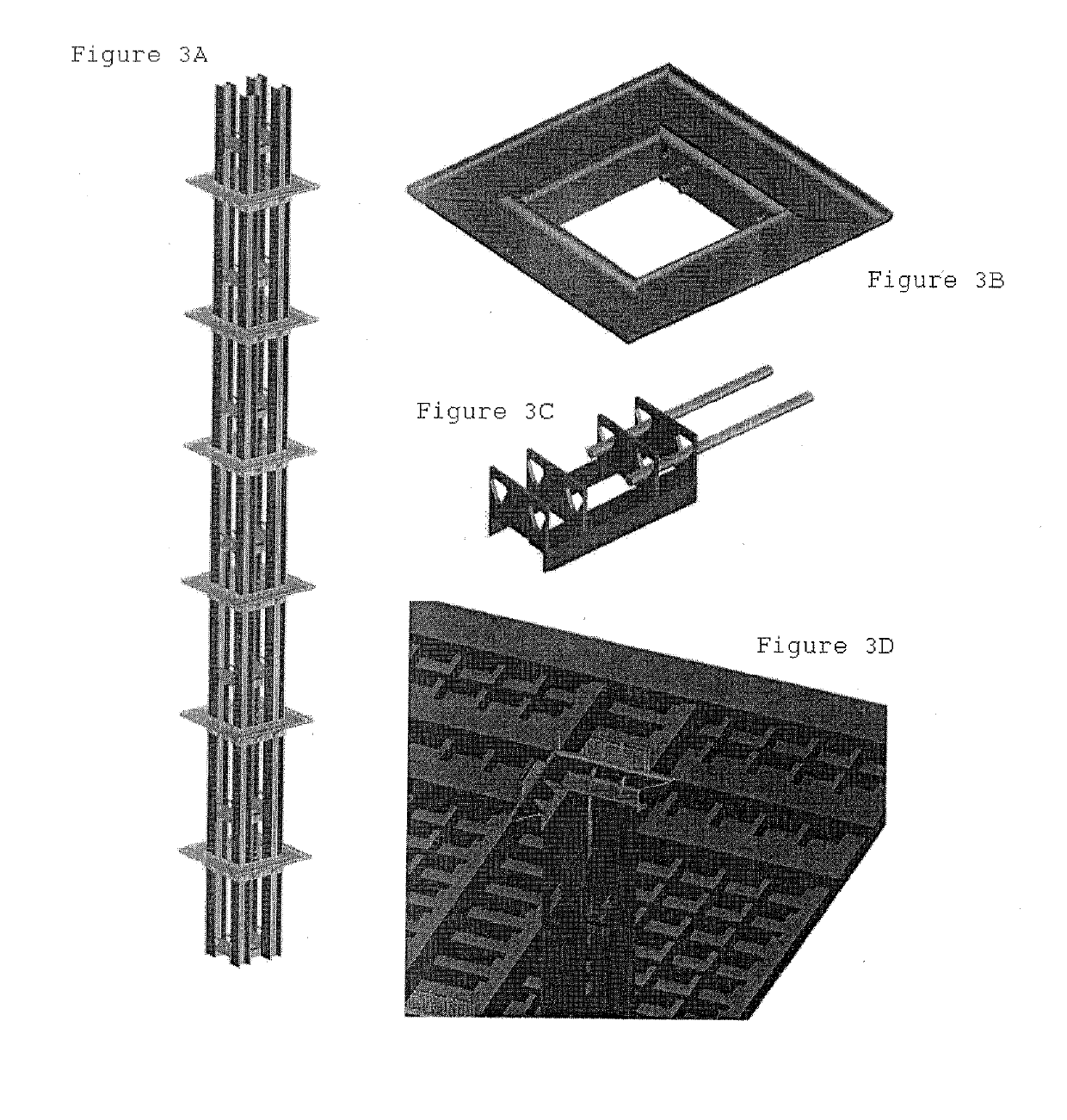

[0049]The present invention describes the industrial process for building buildings comprising the steps of:[0050]a) Execution of the staking;[0051]b) Concreting the foundation blocks and securing the formwork to the ground;[0052]c) Assembly of the operational platform;[0053]d) Assembly of the columns;[0054]e) Casting of chassis on the operational platform;[0055]f) Lifting of the chassis;[0056]g) Closing and finishing of floors;[0057]h) Replacement of the last module of the columns and installation of elevators and stairs;[0058]i) Interconnection of utility systems;[0059]j) Removal of operational platform and formwork.

[0060]It is important to point out that, before beginning the construction process as described here, some steps inherent to any type of construction are necessary:[0061]Development of an Architectural Project defining the occupation of the standardized area for a type pavement, which will lead to the development of executive construction projects.[0062]Positioning of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com