Roll forming apparatus and system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

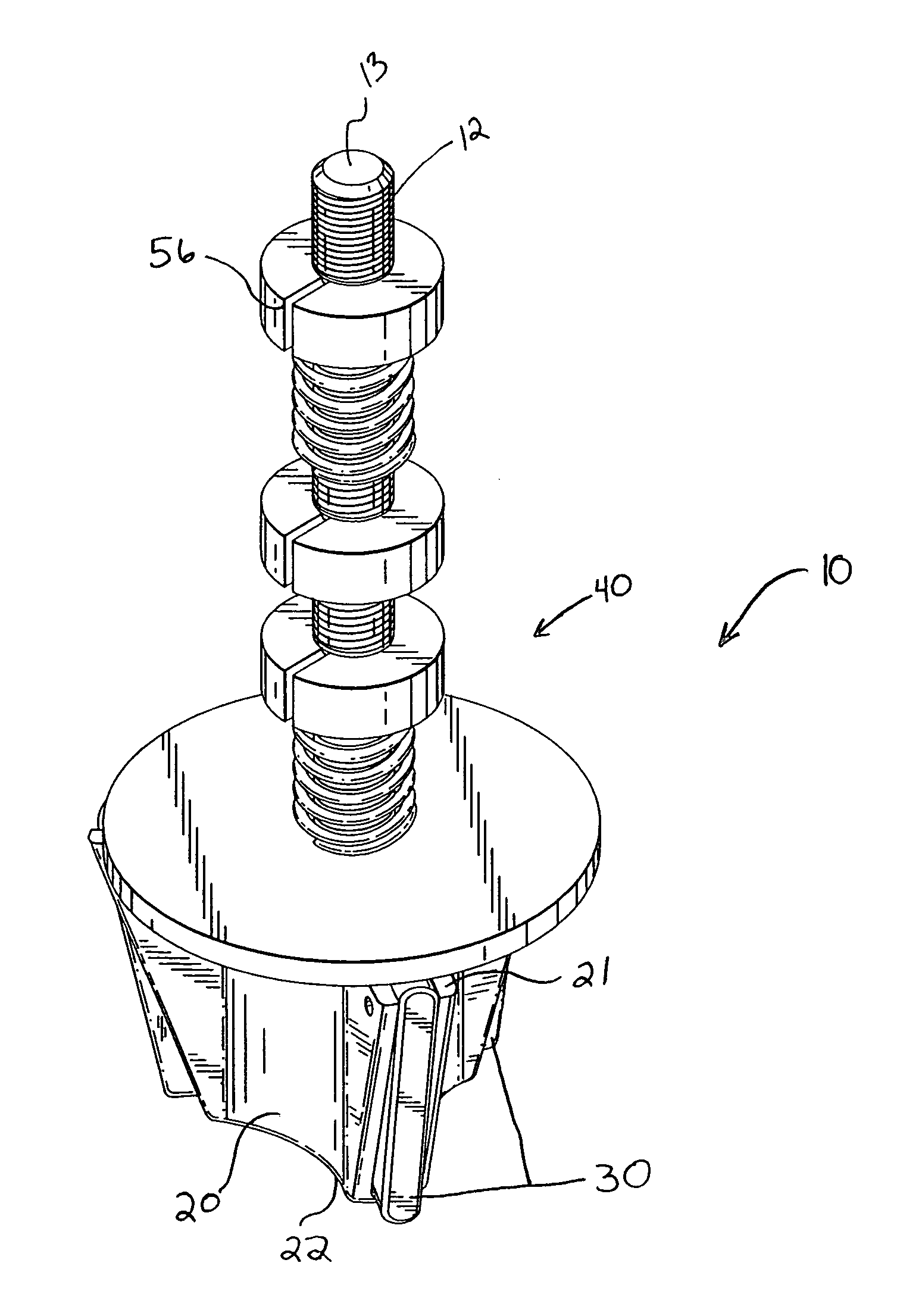

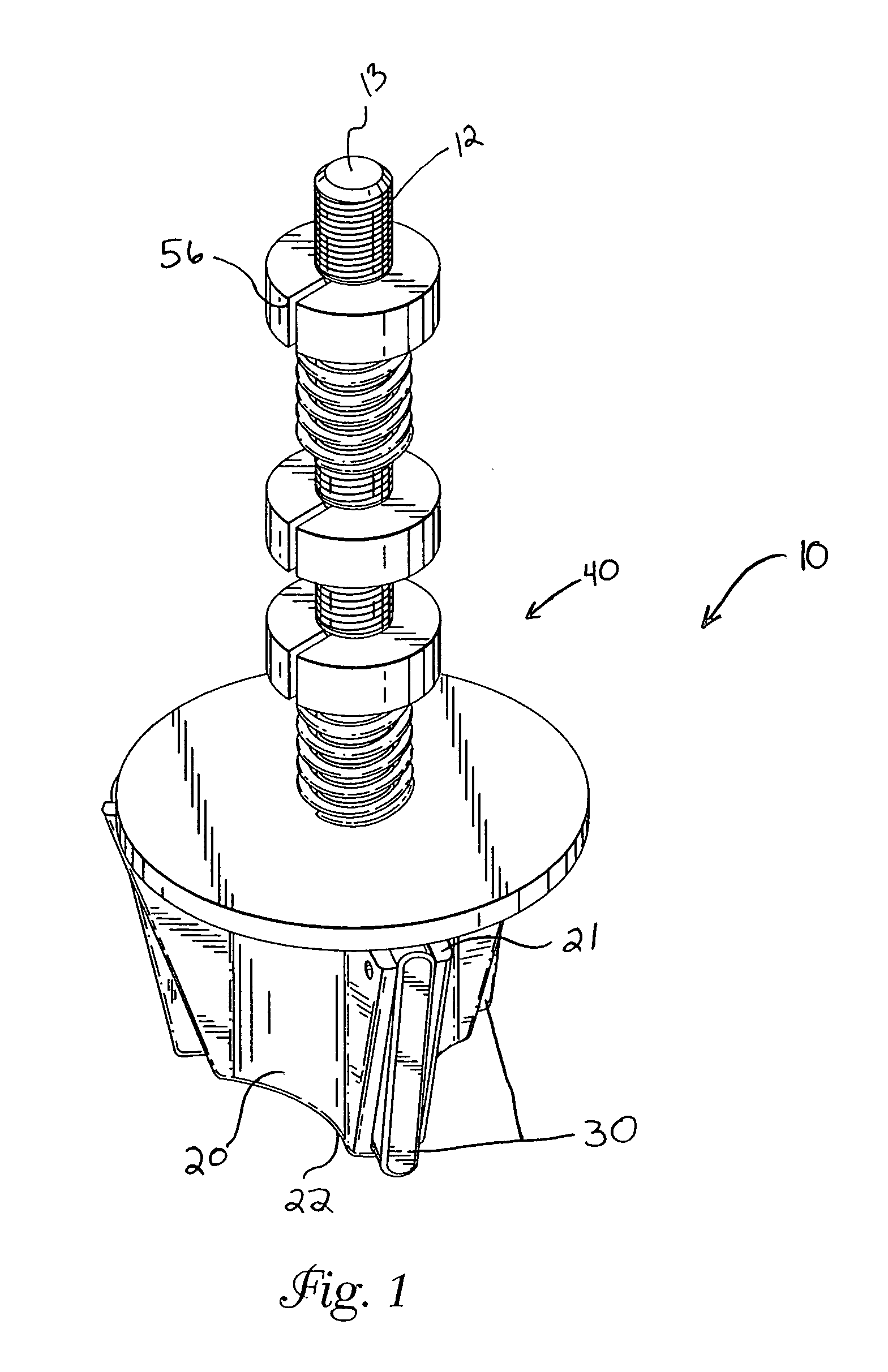

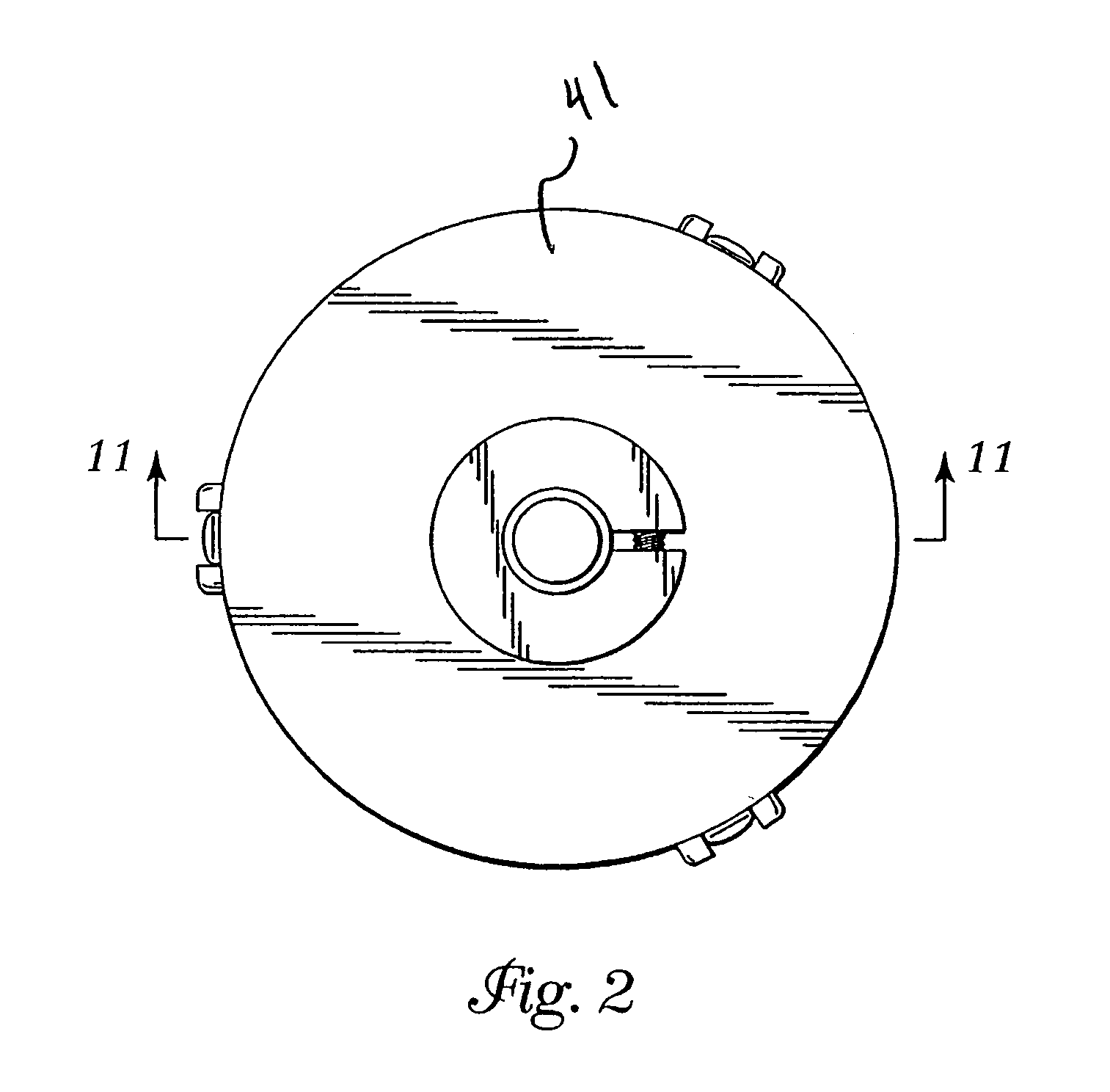

[0021]In an embodiment of the invention, a roll forming apparatus or device is provided, as shown generally at 10 in FIG. 1, the device being capable of forming a multi-lobed roll from a unit of dough. In an example embodiment, the roll forming apparatus of the invention comprises a head member disposed on a shaft member for supporting the head member above a baking container having a bottom wall and at least one peripheral wall. The head member has a plurality of outwardly radiating arms and a plurality of guide blades. Each of the guide blades is disposed in an interior of a respective arm and cantilevers between an extended position and a retracted position. A tension assembly is also included for adjusting the resistance of the guide blades from moving from the extended position toward the retracted position. In another embodiment, a securing assembly is mountable about the shaft member for pivotally securing the shaft member to a rack or a supporting plate above a baking pan.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com