Packaging bag, and method for storing melt-processable polyvinyl alcohol resin with the use of the packaging bag

a technology of polyvinyl alcohol resin and packaging bag, which is applied in the field of packaging bags, can solve the problems of difficult stably melting-processing of pva resin, insufficient removal of organic solvent from pva resin, and inability to wash water-soluble pva resin, etc., and achieves the effect of cost and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

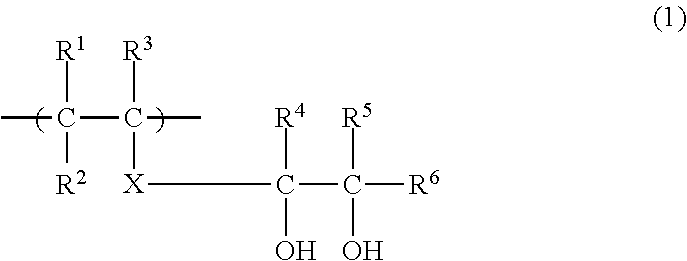

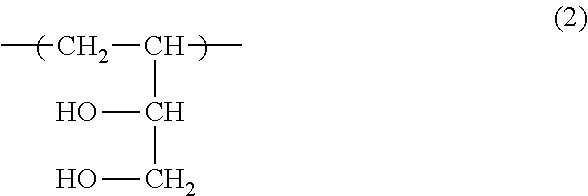

[Side-Chain 1,2-Diol-Containing PVA Resin]

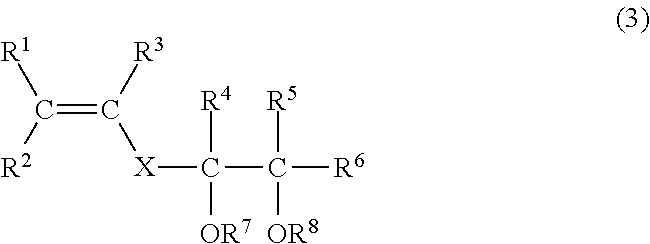

[0078]First, 76.6 parts (an initial feed ratio of 40%) of vinyl acetate, 14.2 parts of methanol and 9.2 parts (an initial feed ratio of 40%) of 3,4-diacetoxy-1-butene were fed into a reaction vessel provided with a reflux condenser and a stirrer, and then azobisisobutyronitrile was fed into the reaction vessel in an amount of 0.068 mol % based on the amount of the fed vinyl acetate. The resulting mixture was heated while being stirred in a nitrogen stream. Then, the rests of vinyl acetate and 3,4-diacetoxy-1-butene were fed dropwise at a constant rate for 13.5 hours, whereby polymerization was allowed to proceed. When the polymerization degree of vinyl acetate reached 91%, m-dinitrobenzene was added to the resulting mixture to terminate the polymerization. Subsequently, methanol vapor was blown into the resulting mixture, whereby unreacted vinyl acetate monomer was removed to the outside. Thus, a methanol solution of a copolymer was obtained...

example 2

[0088]A packaging bag was produced as having the same structure in substantially the same manner as in Example 1, except that the low-density polyethylene film for the methanol vapor permeable film layer had a thickness of 50 μm. The 50-μm thick low-density polyethylene film had a methanol vapor transmission rate of 7 g / m2·day (at 23° C. at 50% RH) and a water vapor transmission rate of 18 g / m2·day (at 40° C. at 90% RH). The pelletization of PVA resin stored in the packaging bag thus produced was evaluated in the same manner as in Example 1. The evaluation result is shown below in Table 1.

example 3

[0089]A packaging bag was produced as having the same structure in substantially the same manner as in Example 1, except that the low-density polyethylene film had a thickness of 30 μm. The 30-μm thick low-density polyethylene film had a methanol vapor transmission rate of 12 g / m2·day (at 23° C. at 50% RH) and a water vapor transmission rate of 30 g / m2·day (at 40° C. at 90% RH). The pelletization of PVA resin stored in the packaging bag thus produced was evaluated in the same manner as in Example 1. The evaluation result is shown below in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| vapor transmission rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| methanol vapor transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com