Resorbable crosslinked form stable membrane for use outside the oral cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

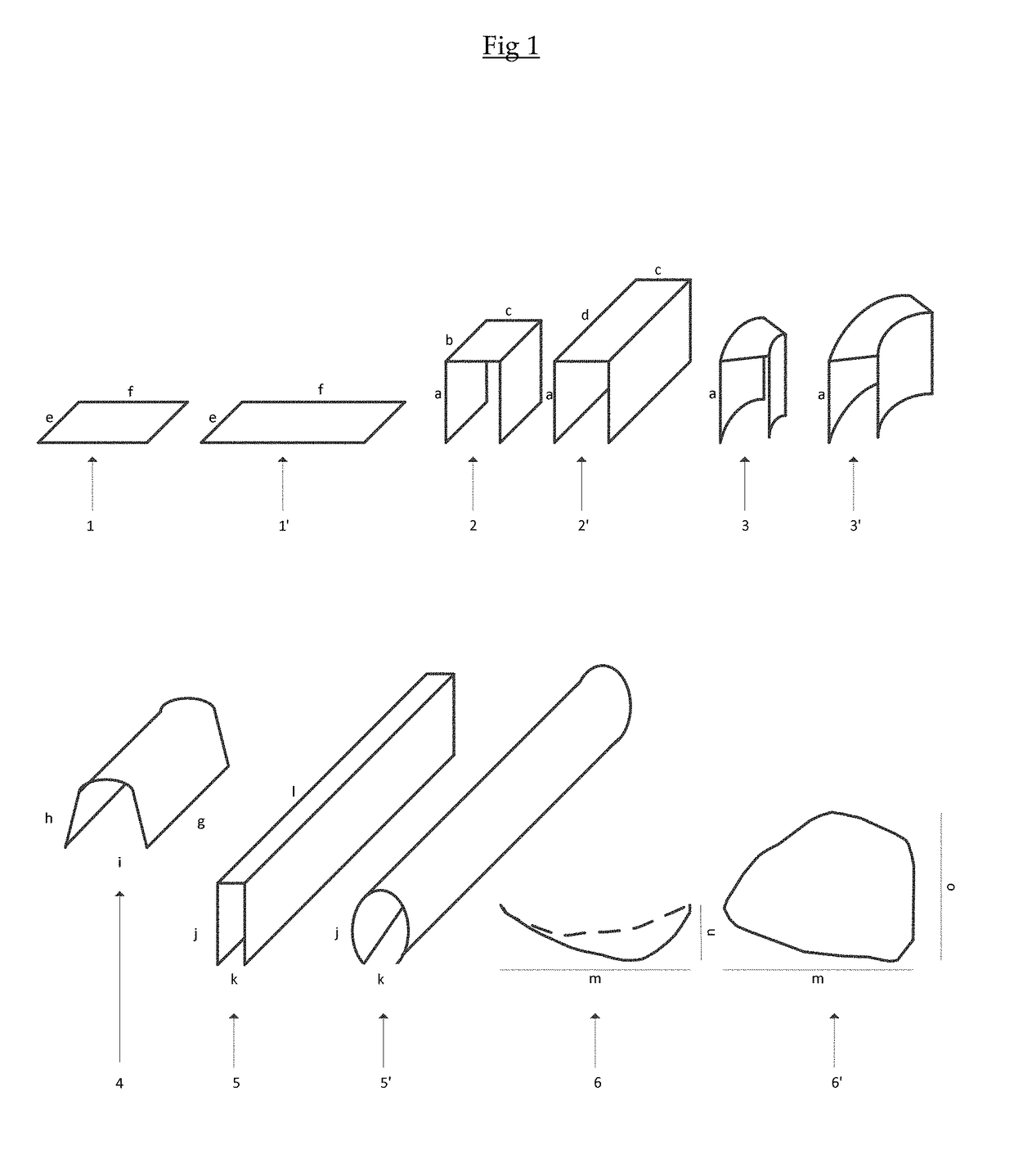

Image

Examples

example 1 preparation

OF THE RAW MATERIALS

[0148]Preparation of Hydroxyapatite Fine Particles Having a Size of 250 to 400 μm (A)

[0149]Hydroxyapatite bone mineral fine particles were produced from cortical or cancellous bone as described in Examples 1 to 4 of U.S. Pat. No. 5,417,975, using an additional sieving step between 250 and 400 μm.

[0150]Alternatively, hydroxyapatite bone mineral fine particles were produced by grinding Geistlich Bio-Oss® Small Granules (available from Geistlich Pharma AG, CH-6110, Switzerland) by careful impactation using a pistol and an additional sieving step between 250 and 400 μm.

[0151]The hydroxyapatite bone mineral fine particles having a size of 250 to 400 μm prepared above (A) were stored in glass bottles until use.

[0152]Preparation of Collagen Fibres (B)

[0153]As described in “Example” of EP-B1-1676592, peritoneal membranes from young pigs were completely freed from flesh and grease by mechanical means, washed under running water and treated with 2% NaOH solution for 12 hou...

example 2

PREPARATION OF AN OPTIONALLY CROSSLINKED HYDROXYAPATITE / COLLAGEN PLATE (E)

[0163]4 g of collagen fibres (B) and 6 g of cutting mill collagen fibre segments (C) prepared in Example 1 were mixed with 140 g of phosphate buffered saline and shaked in a cocktail mixer. In another example, collagen fibres were substituted completely by cutting mill collagen fibre segments.

[0164]20 to 30 g hydroxyapatite fine particles (A) prepared in Example 1 were added and mixed by hand.

[0165]34.14 g of this mixture were centrifuged at 7000×g (7000 times the acceleration of gravity) for 2 minutes.

[0166]The pellet was poured between two polyamide-nets (of pore size 21 μm and a total of 17% of open structure) in a flat rectangular form of 8×12 cm and the matter was condensed by removing excess water with a laboratory spoon. The plates obtained were compressed at a pressure of 1-1.7 kPa and dried in a vacuum oven at 30° C. / 50 mbar for 2 hours, then at 30° C. / 10 mbar for 8 hours. The polyamide-nets were remo...

example 3

PREPARATION OF A RESORBABLE CROSSLINKED FORM STABLE MEMBRANE (M) BY ASSEMBLING AND GLUING TWO ELASTIC PRETENSED COLLAGEN LAYERS ON THE TWO OPPOSITE FACES OF THE HYDROXYAPATITE / COLLAGEN PLATES (E)

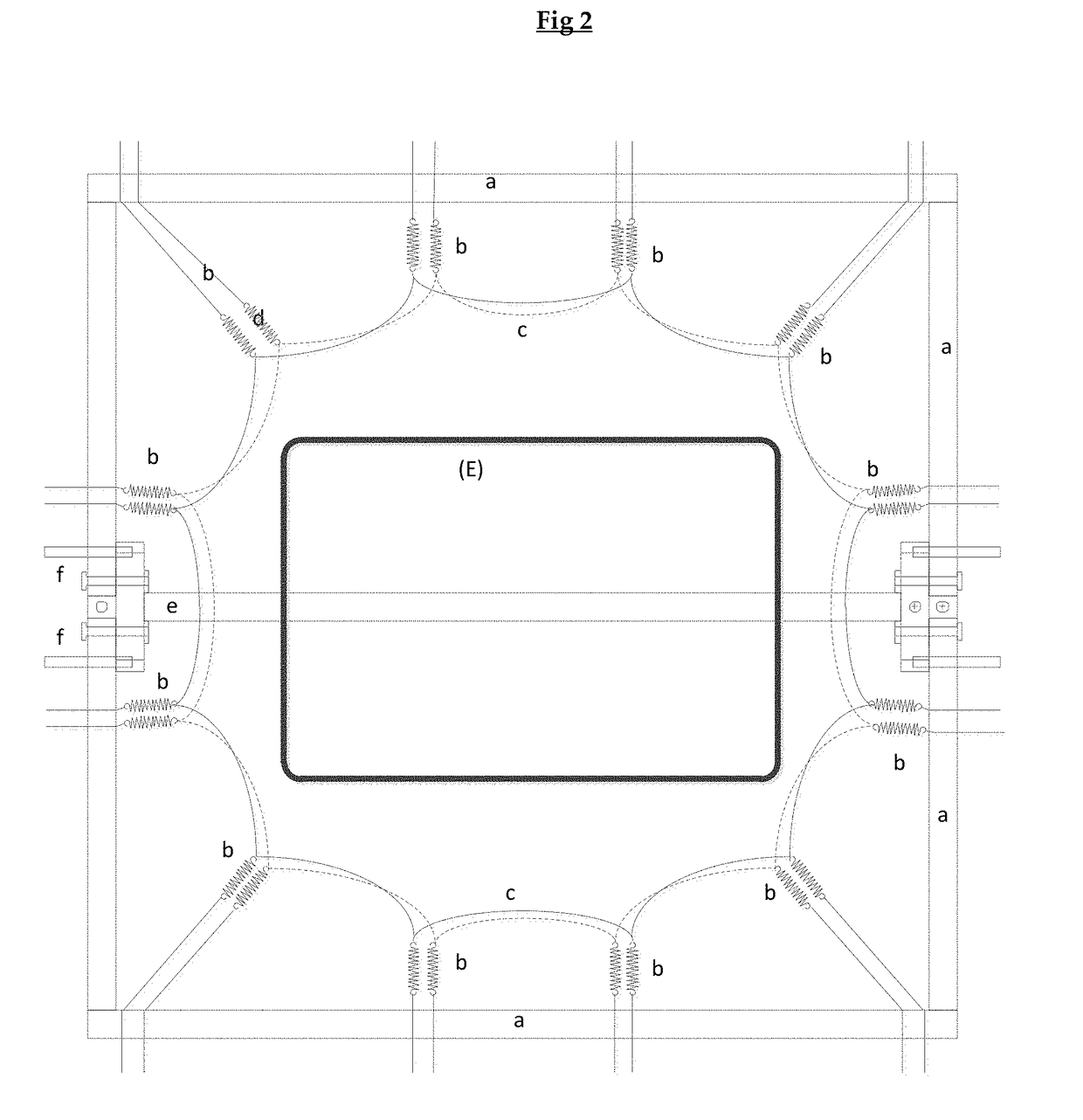

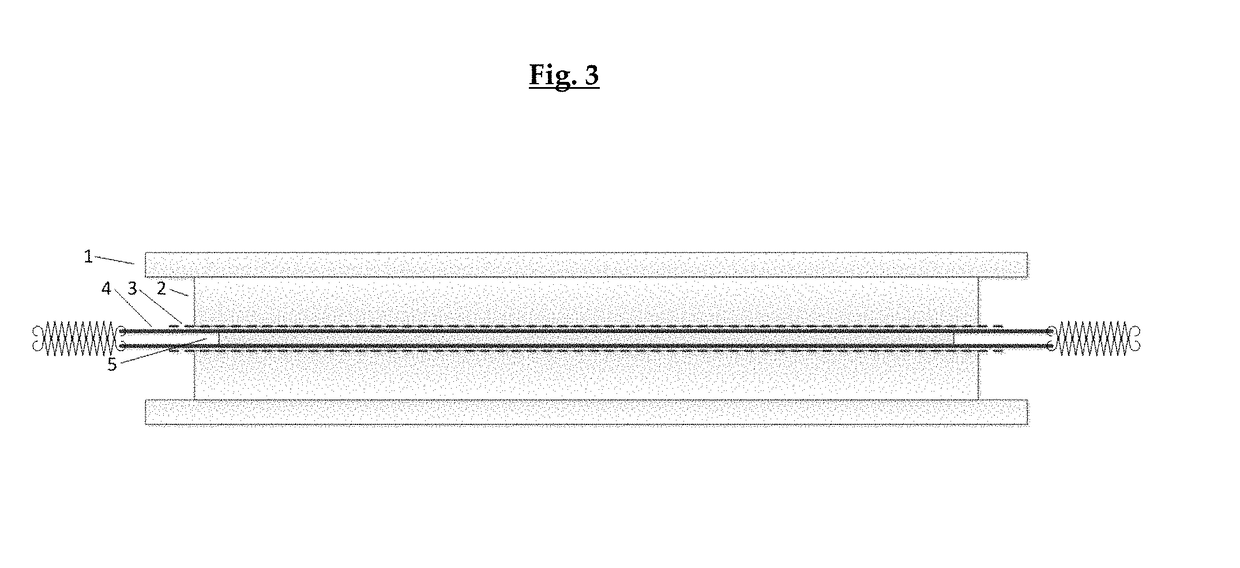

[0172]The following description will be better understood by referring to FIGS. 2 and 3. The assembly of a flat or U-shaped prototype requires the use of fixed or bendable frames enabling the tensioning of the layers of collagen material.

[0173]Forming of Flat or U-Shaped Prototypes (F)

[0174]FIG. 2 is a schematic view of equipment suitable for enabling the tensioning of the layers of collagen material prior to their assembling into a flat or U-formed form stable membrane of the invention.

[0175]That equipment consists of a frame (a), which can be made of any suitable material, e.g. steel or aluminum. The main purpose for the frame is to anchor the springs (b), which tension the two wet collagen layers (c). The hydroxyapatite / collagen plate (E) was positioned in between the two collagen layers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com