Method of producing wear-resistant iron-based sintered alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

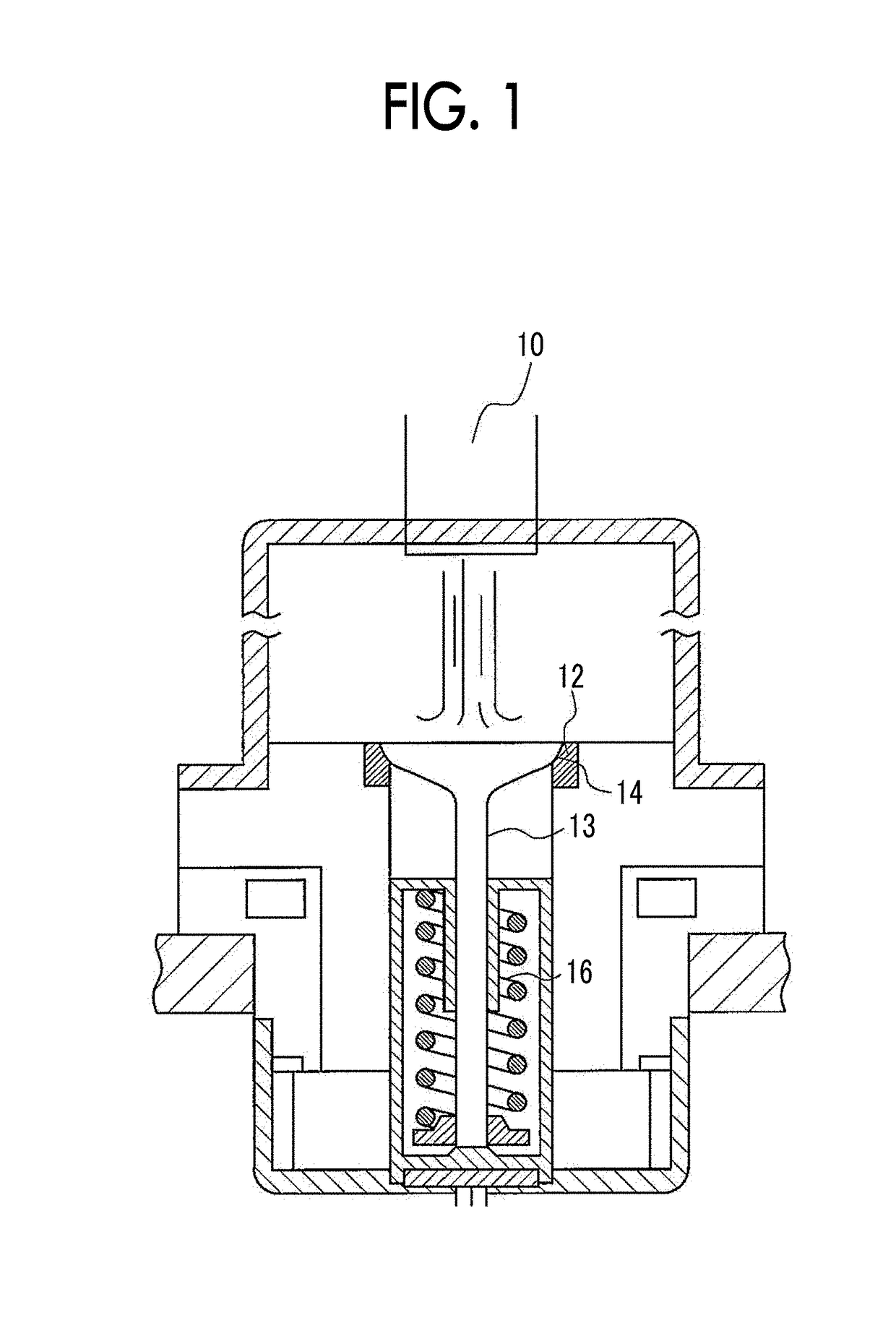

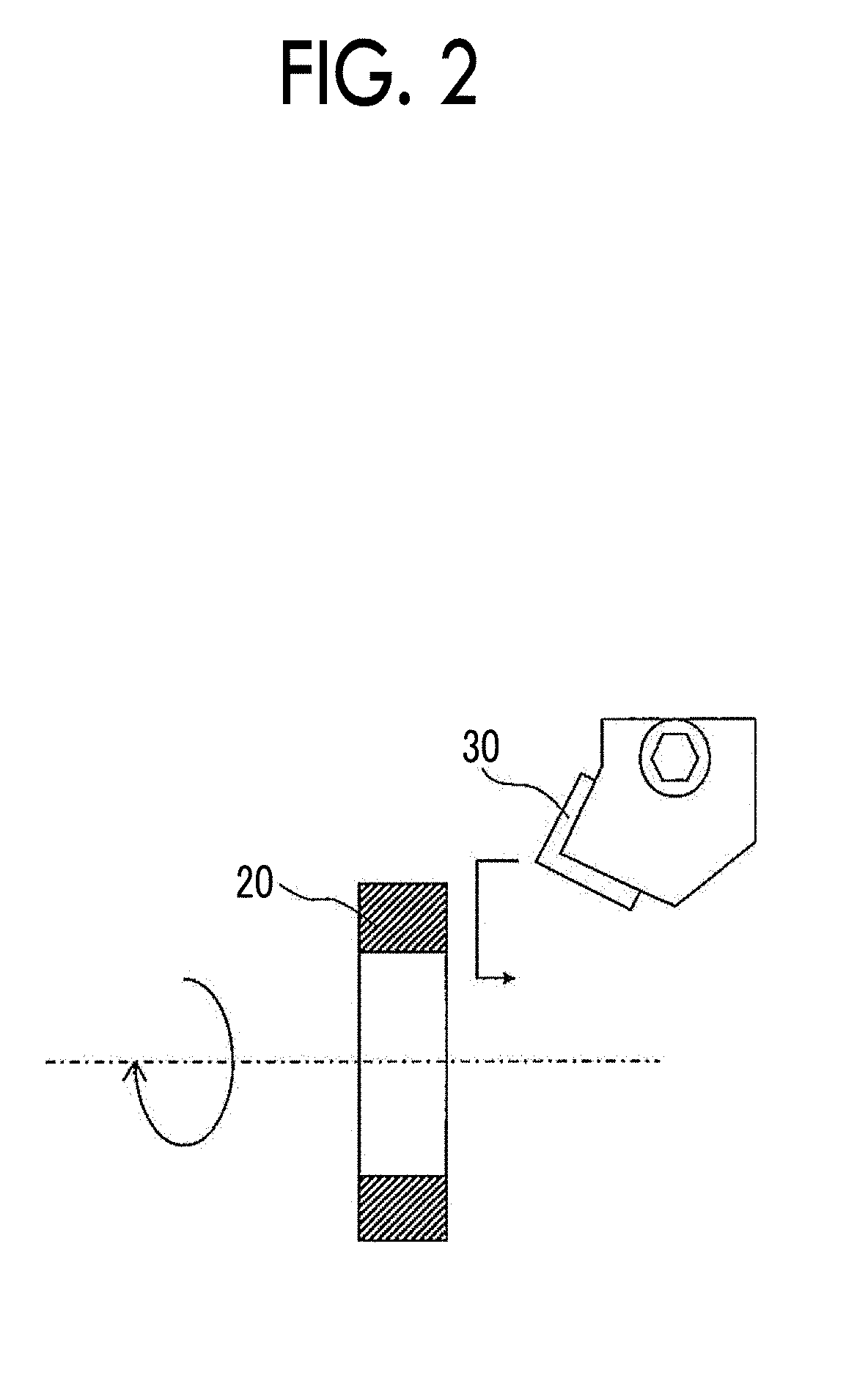

Method used

Image

Examples

example 1

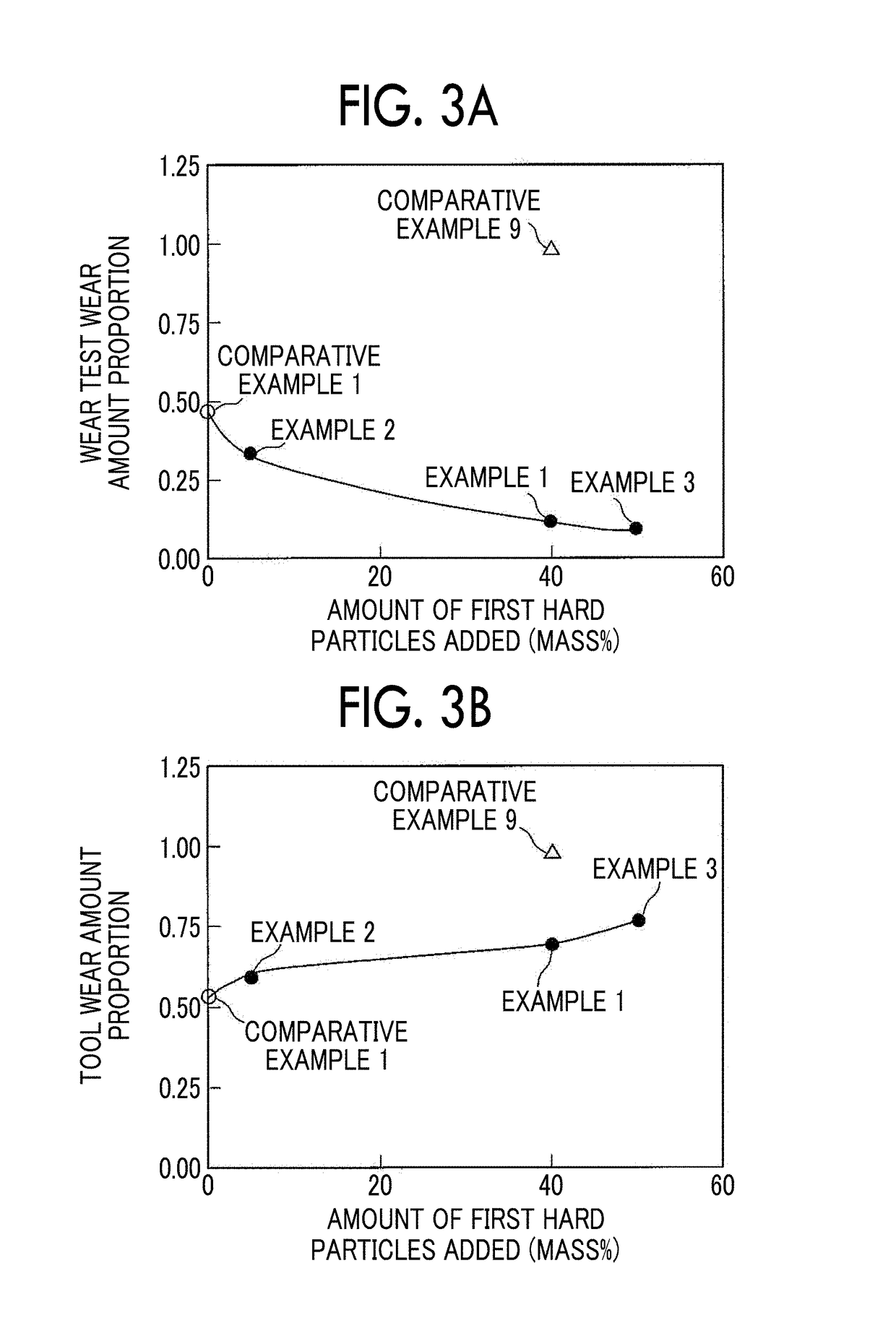

Optimal Amount of First Hard Particles Added

[0098]A sintered alloy according to Example 1 was produced according to the following production method. As the first hard particles, hard particles (commercially available from Daido Steel Co., Ltd) produced from an alloy including Mo: 40 mass %, Ni: 30 mass %, Co: 20 mass %, Mn: 5 mass %, Si: 0.8 mass %, and C: 1.2 mass %, with the balance including Fe and inevitable impurities (that is, Fe-40Mo-30Ni-20Co-5Mn-0.8Si-1.2C) using a gas atomizing method were prepared. The first hard particles were classified into a range of 44 μm to 250 μm using a sieve according to JIS standard Z8801. Here, “granularity of particles” in this specification is a value obtained by classification according to this method.

[0099]As the second hard particles, second hard particles (commercially available from Kinsay Matec Co., Ltd) produced from an Fe-65 alloy including Mo: 65 mass %, with the balance including Fe and inevitable impurities using a grinding method ...

examples 2 and 3

Optimal Amount of First Hard Particles Added

[0102]In the same manner as in Example 1, sintered alloy test pieces were prepared. Examples 2 and 3 were examples for evaluating an optimal amount of first hard particles added. Examples 2 and 3 differed from Example 1 in that, as shown in Table 1, the first hard particles were added at a proportion of 5 mass % and 50 mass %, respectively, with respect to the entire mixed powder.

examples 4 and 5

Optimal Amount of Second Hard Particles Added

[0103]In the same manner as in Example 1, sintered alloy test pieces were prepared. Examples 4 and 5 were examples for evaluating an optimal amount of second hard particles added. Examples 4 and 5 differed from Example 1 in that, as shown in Table 1, the second hard particles were added at a proportion of 1 mass % and 5 mass %, respectively, with respect to the entire mixed powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com