Bonded Insulation Product Batt From Spent Carpet And Waste

a technology of bonded insulation and waste, which is applied in the direction of textiles and papermaking, mechanical equipment, other domestic objects, etc., can solve the problems of not being able to reliably use as insulation in bedding, the batt formed is not a bonded and readily handled insolation, and the 868 patent does not teach a thermal insulation product bonded with bi-component fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

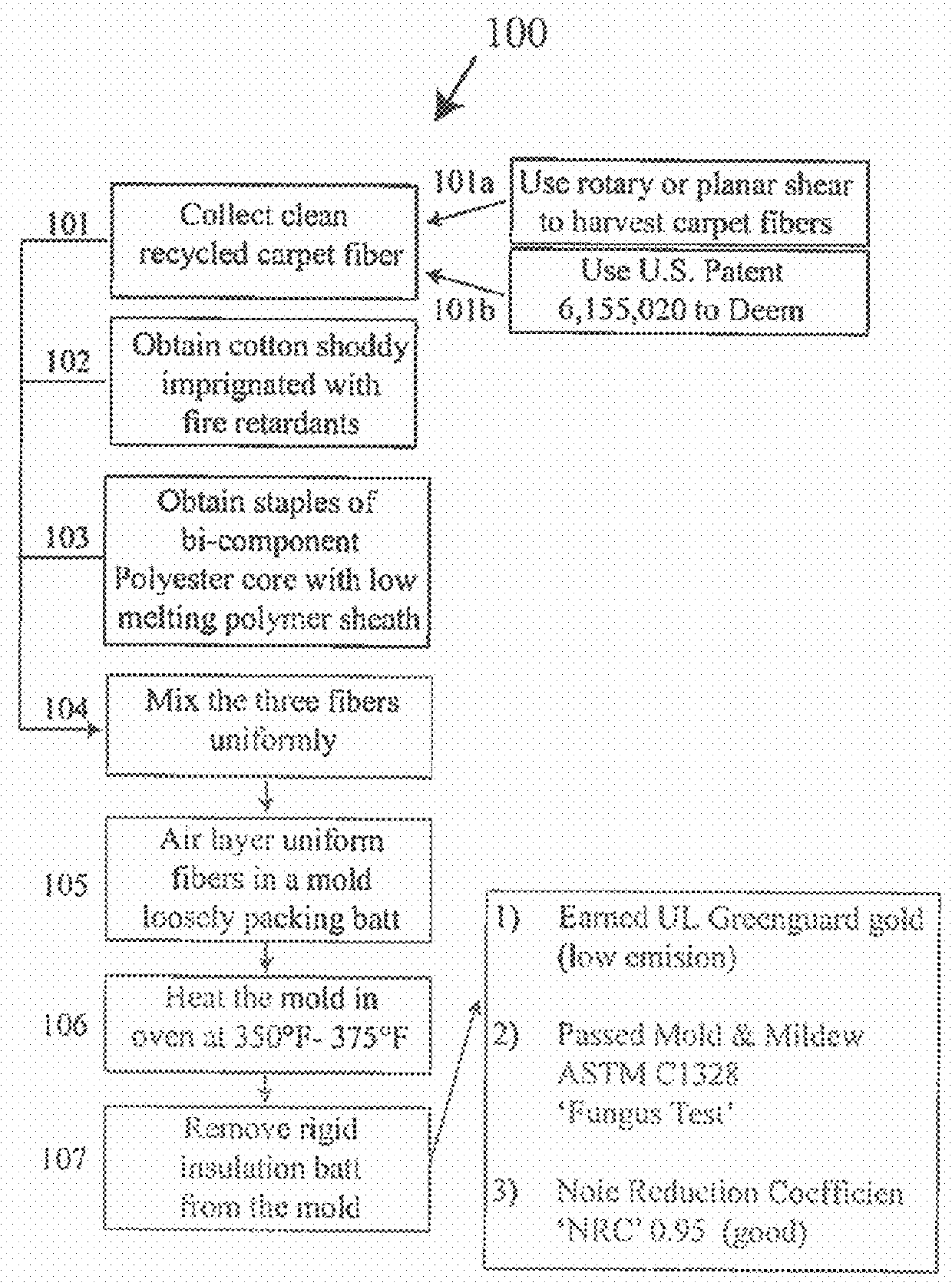

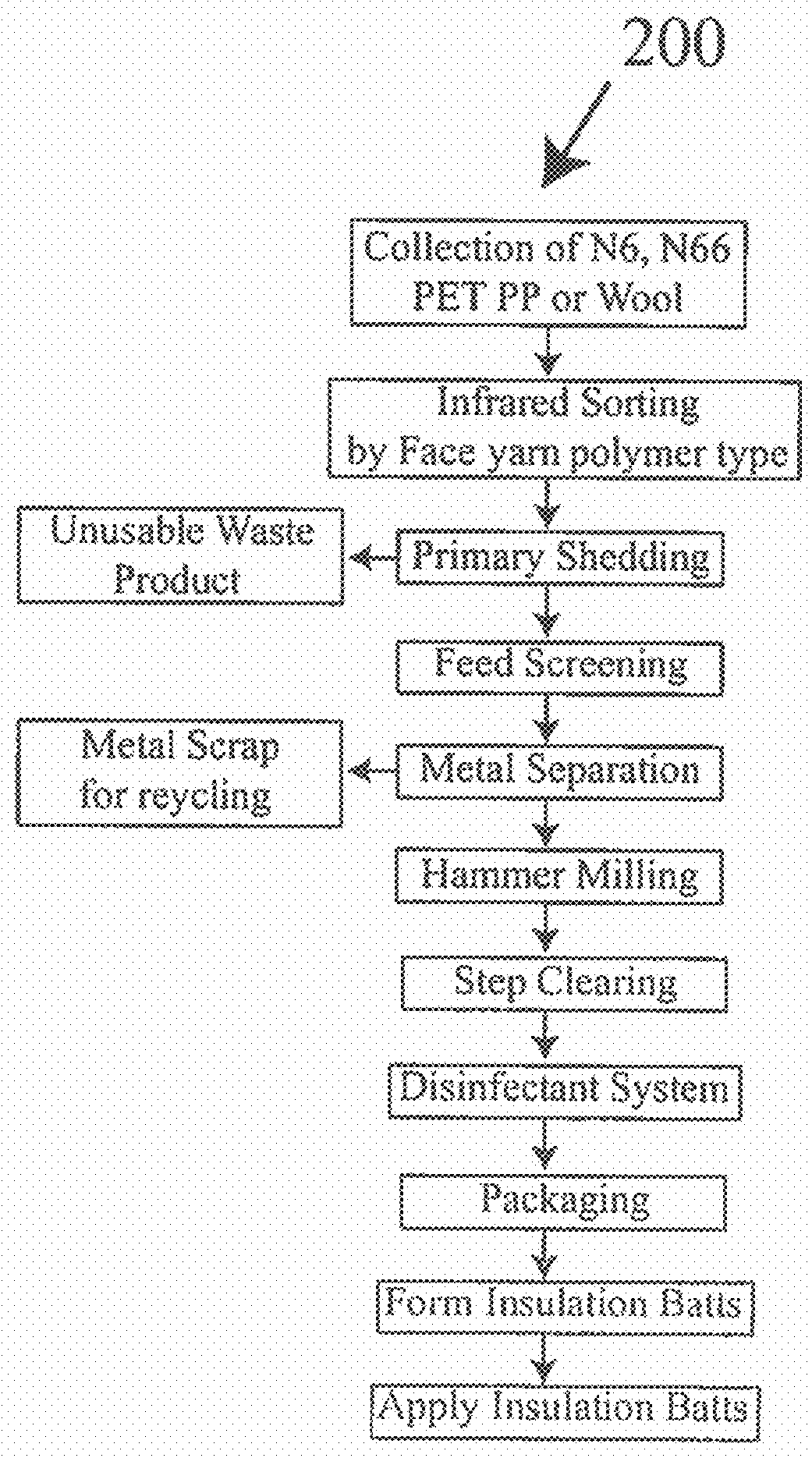

[0035]This invention relates to forming a rigid bonded insulation batt made from carpet fiber of spent carpets. This invention has enormous impact on the environment since several million tons of spent carpets are discarded in landfills and these carpets do not readily degrade. Due to its low bulk density, carpet waste can be voluminous. Therefore, recycling of these carpets and rugs would have a significant impact on efforts to effectively reduce plastic components in municipal waste streams. Carpet scraps of the sort noted above, can prove to be a valuable resource if the plastic generated from recycling can be used for other useful applications rather than being discarded into municipal waste streams.

[0036]The present invention takes advantage of any carpet fiber to effectively bond forming a loosely bonded low density batt, which is thermally insulating due to trapping air pockets. The bonding process of the fibers should not result in excessive melt flow since this closes off a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com