Unit Cell Titanium Casting

a titanium casting and unit cell technology, applied in casting apparatus, metal-working apparatus, manufacturing tools, etc., can solve the problems of loss of substantial heat, increase costs, and time-consuming preparation of molding shells, so as to improve the efficiency of equipment, reduce pressure, and optimize the filling of complex geometries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

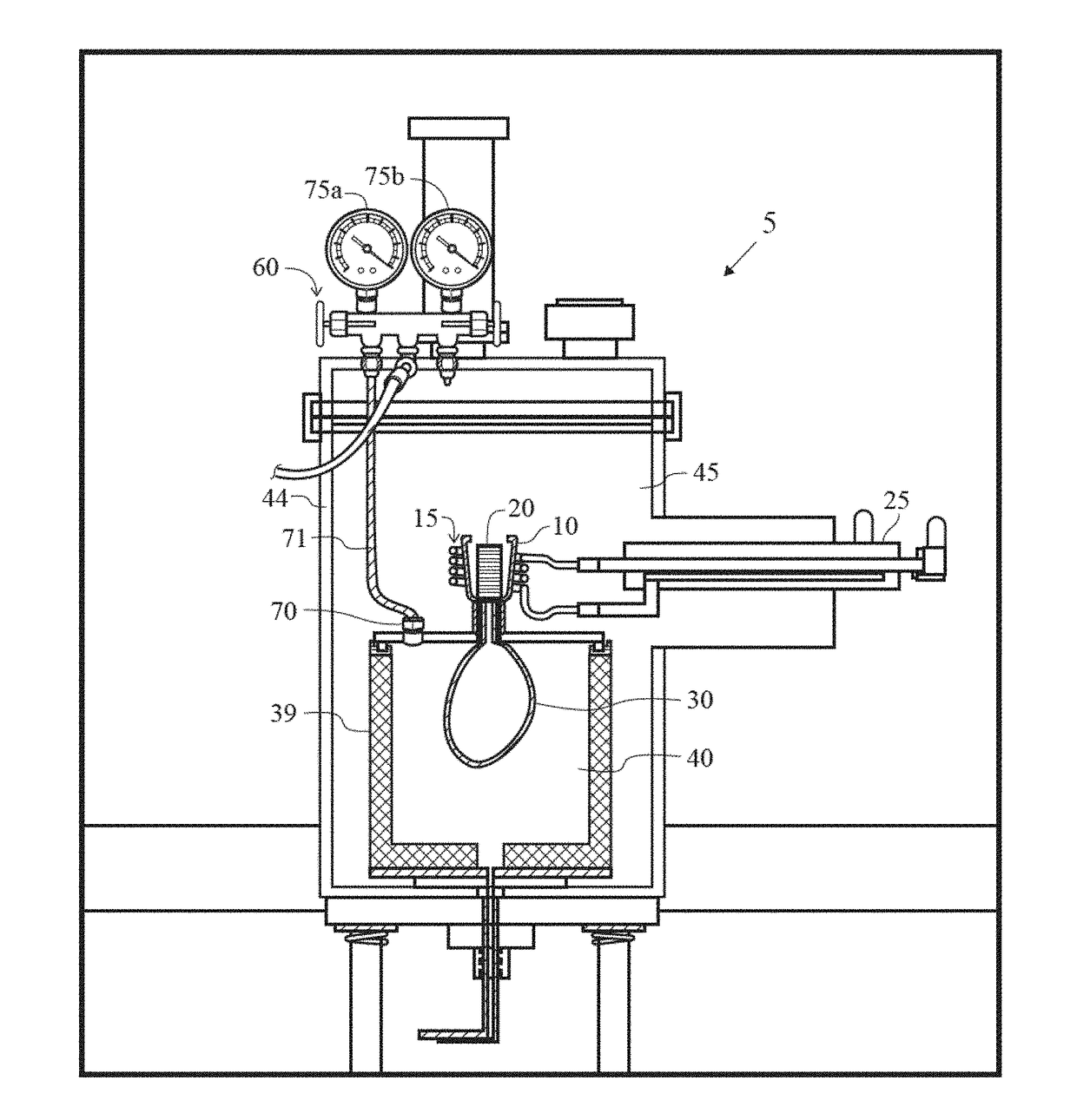

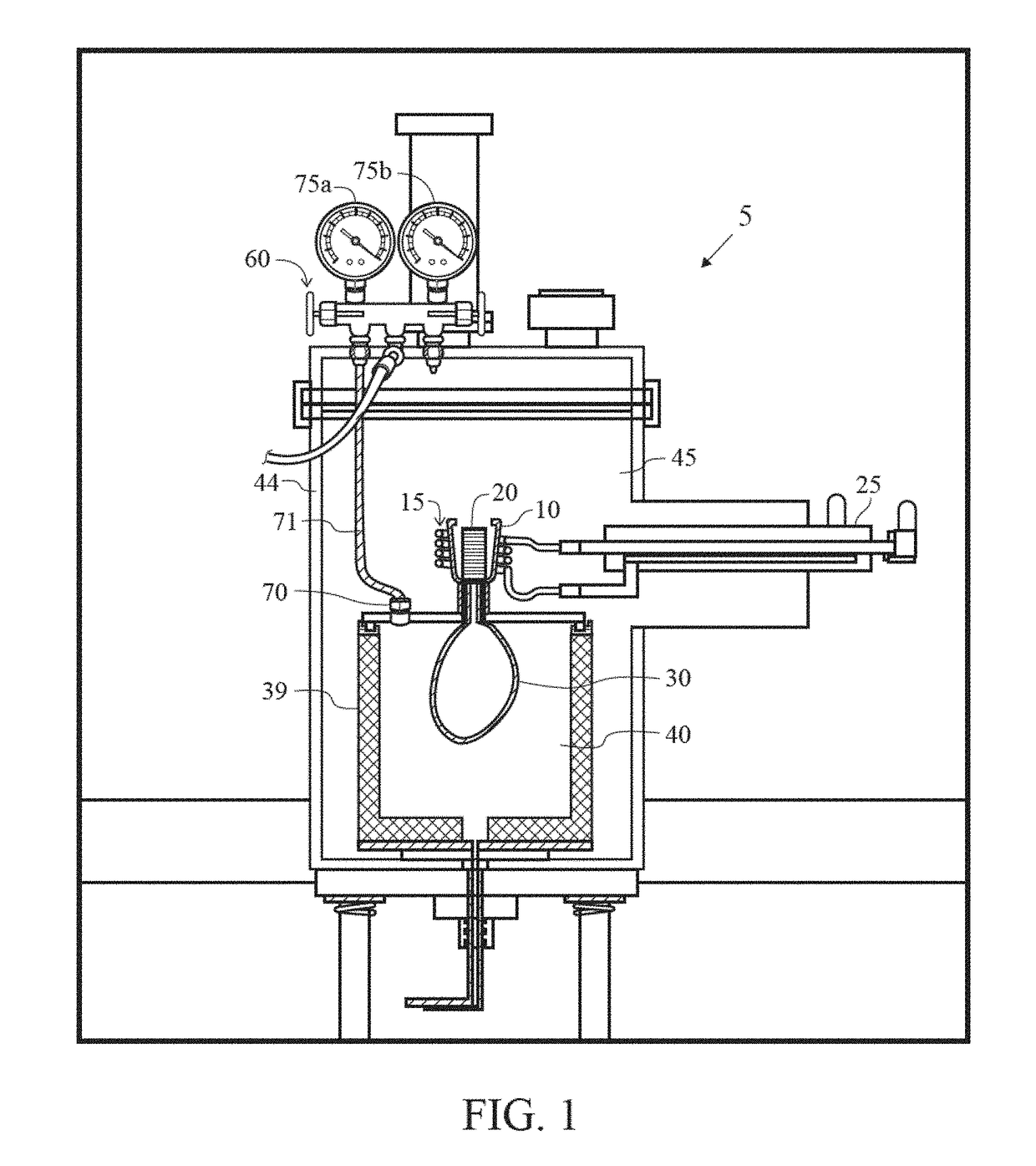

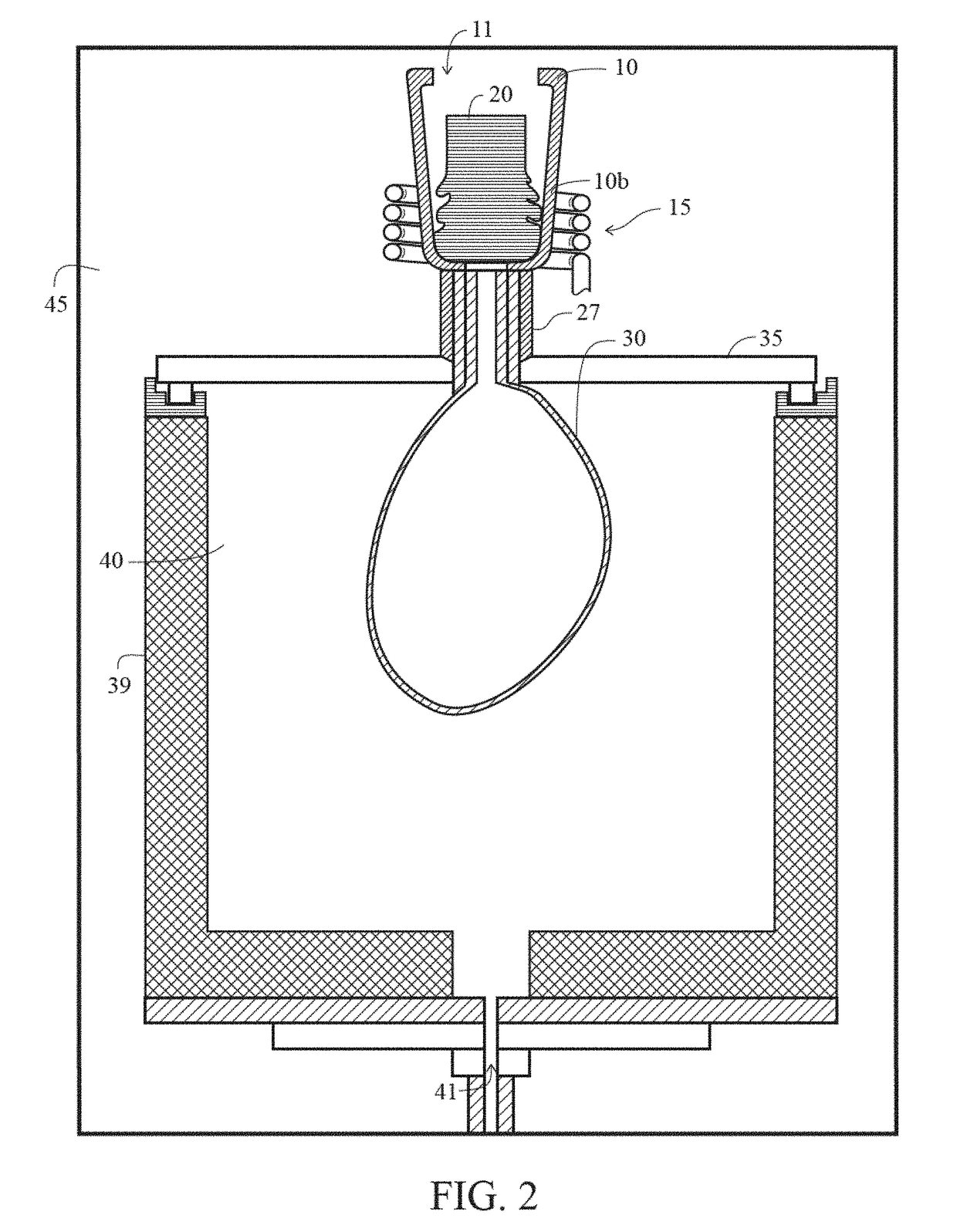

Embodiment Construction

[0038]During the casting process it is critical to ensure that the material be heated sufficiently and consistently in order to ensure proper flow into the pattern mold. Especially with the use of a bottom-fed / gravity flow system, having the ability to precisely control the pour time will allow for optimum material heating ensuring desired material properties in the finished part. In order to achieve this a chill plate should be utilized which would help to definitively control the time that the molten material would transition to the pattern mold. The chill plate would be in the shape of a ring, with an opening centered on the opening of the ceramic crucible where the material is being melted. The plate itself would be cooled during melting and then at the optimal pour time, the cooling would be turned off. With the cooling, the seal melts through and the material is evacuated into the pattern mold. The use of this feature will allow for precise evacuation times providing consisten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| atmospheric pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com