Unit Cell Titanium Casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

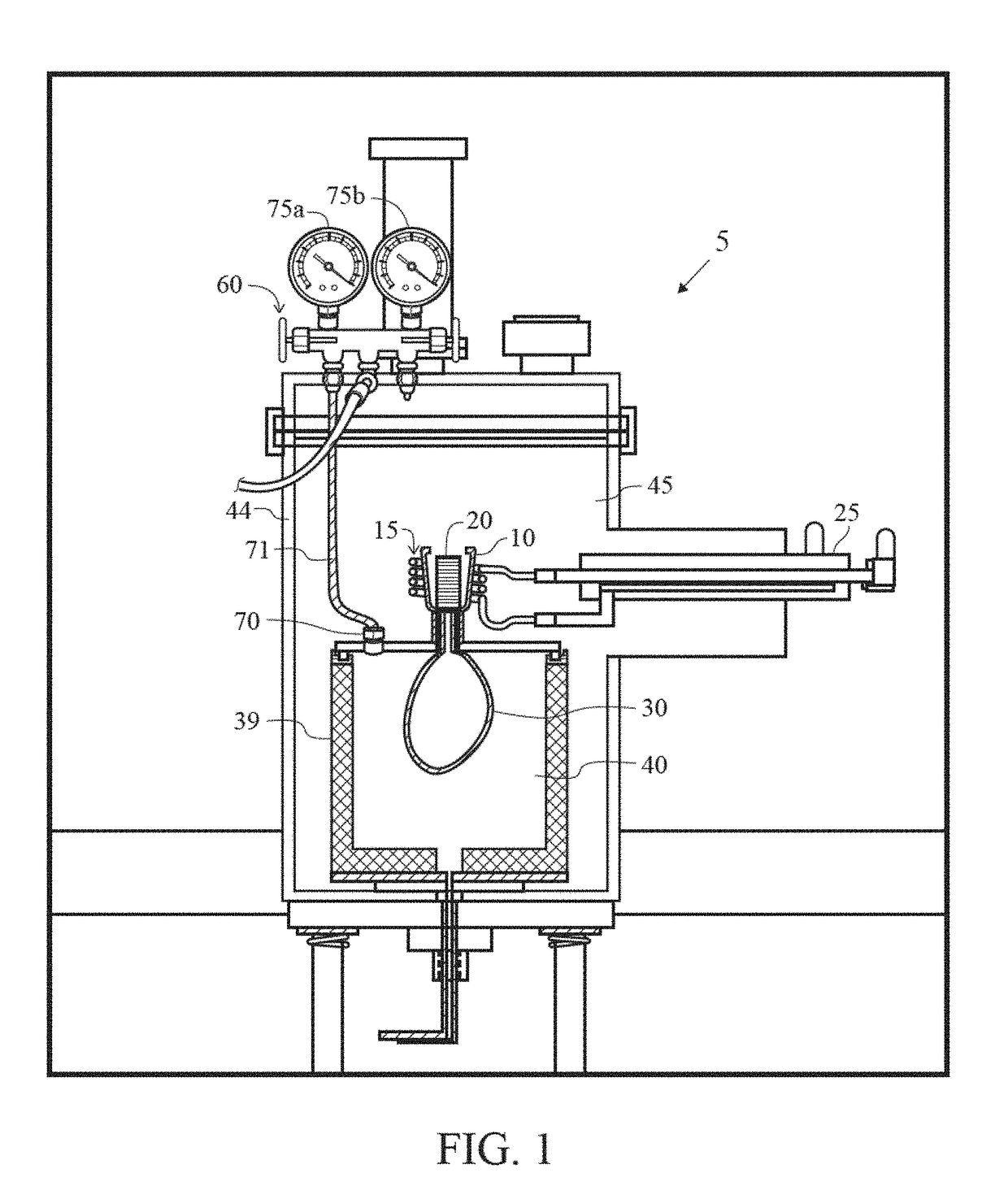

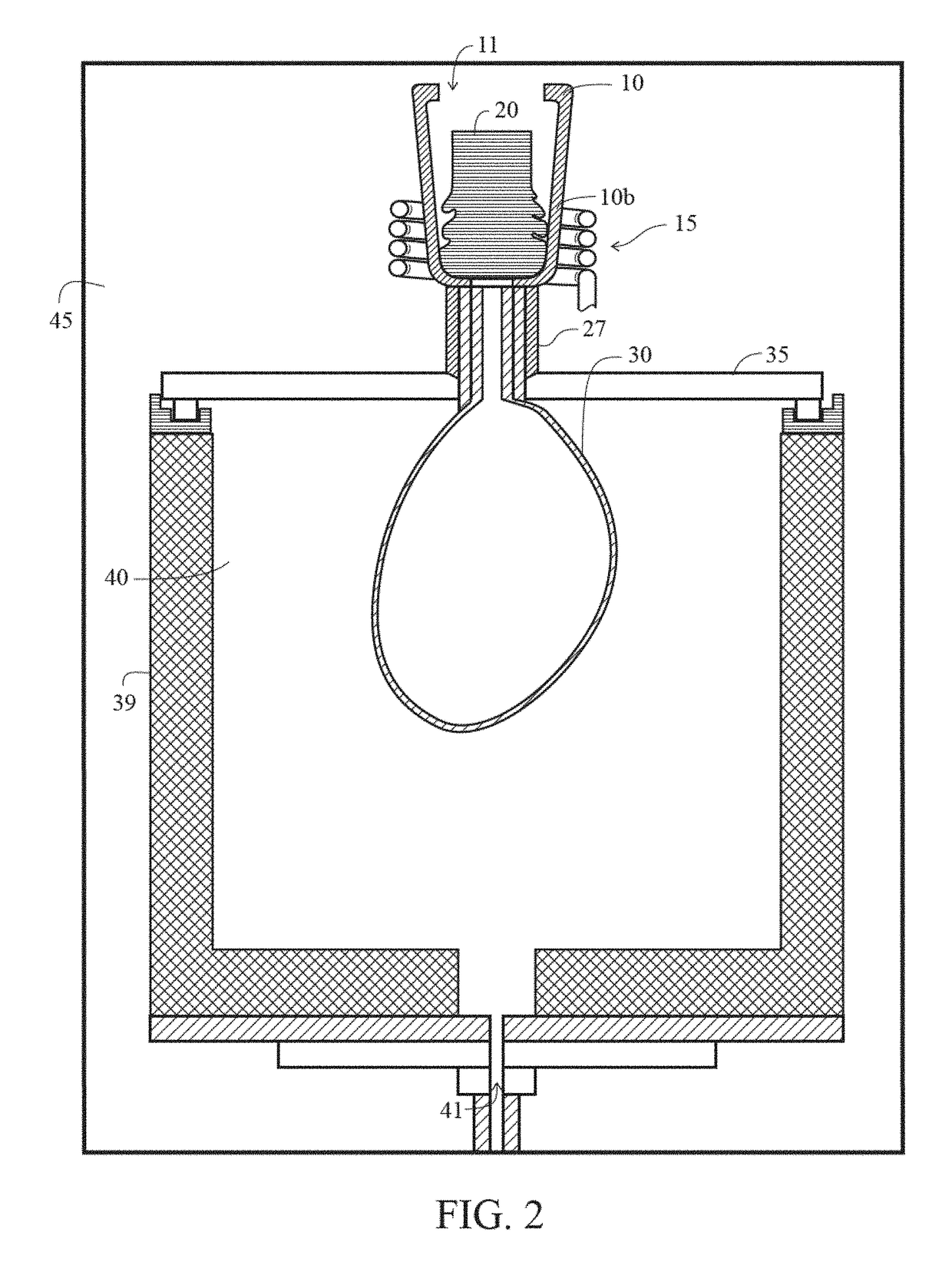

[0037]As shown in FIG. 1, a unit cell titanium casting system 5 comprises an external container 44, an internal container 39, a vacuum mechanism 60, a crucible 10, an induction coil 15, a coil electrical generation mechanism 25, and a mold 30. The external container 44 defines an external chamber 45. The internal container 39 defines an internal chamber 40. The vacuum mechanism 60 includes a vacuum line 71, a vacuum connector 70 and pressure gauges 75a and 75b. The vacuum mechanism 60 is utilized to evacuate and pressurize the external chamber 45 and the internal chamber 40 in order to create a pressure differential between the internal chamber 40 and the external chamber 45.

[0038]The crucible 10 is preferably composed of a ceramic material. In a most preferred embodiment, the crucible 10 is composed of a first layer 11a, a second layer 11b and a silica based third layer 11c, as shown in FIG. 7. A metal ingot 20 is placed within the interior of the crucible 10. The metal ingot 20 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com